A kind of detection method of elemental manganese in lithium manganese phosphate

A detection method and technology for lithium manganese phosphate, applied in the field of chemical analysis, can solve the problems of difficulty in detecting the content of elemental manganese, inability to separate lithium manganese phosphate, and reduced cycle stability, achieving convenient on-site detection, accurate endpoint judgment, and easy observation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

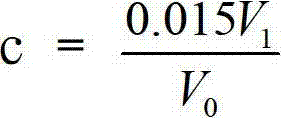

Image

Examples

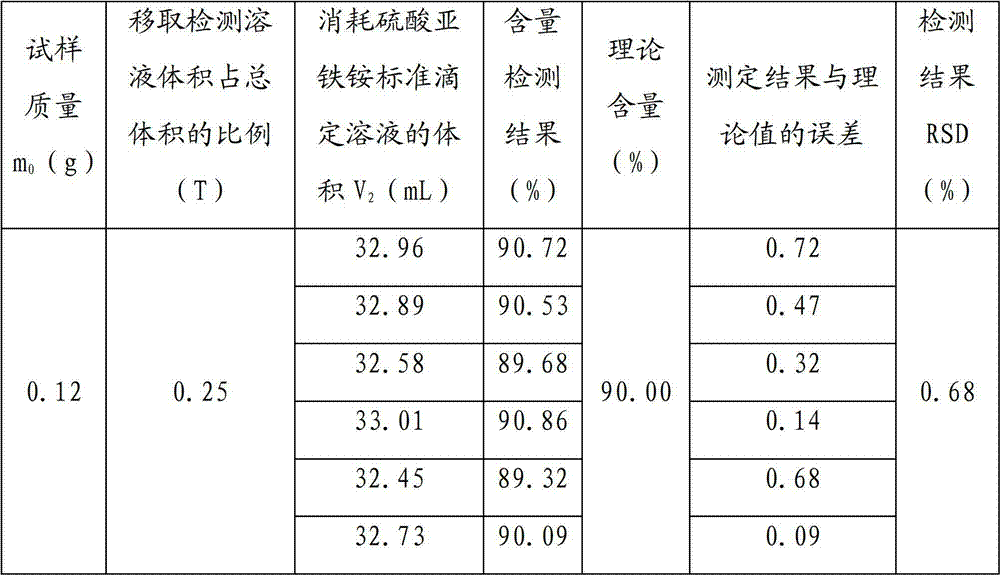

Embodiment 1

[0057] Mix 9.00g of elemental manganese in every 1.00g of pure lithium manganese phosphate, and detect it as a sample, including the following steps:

[0058] (1) Weigh 0.12g of the sample into a conical flask, put it into a stirring bar, add 60mL of ammonium nitrate-ammonia buffer solution, and stir evenly;

[0059] (2) Put the sample obtained in step (1) on the stirrer immediately and heat it for 10 minutes. 100mL volumetric flask, constant volume;

[0060] (3) Pipette 25mL of the solution obtained in step (2) into an Erlenmeyer flask, add 15mL of phosphoric acid, mix well, place on a high-temperature electric furnace to heat, the solution evaporates until phosphoric acid fumes come out, and the temperature is about 220-240°C , stop heating;

[0061] (4) Immediately add 4.0g ammonium nitrate, shake well, let it stand still, remove nitrogen oxides, cool to 50°C, add 60mL deionized water, shake well, continue to cool to room temperature, and then titrate the solution with fe...

Embodiment 2

[0073] Mix 1.00g of elemental manganese in every 9.00g of pure lithium manganese phosphate, and detect it as a sample, including the following steps:

[0074] (1) Weigh 1.15g of the sample into a conical flask, put it into a stirrer, add 60mL of ammonium nitrate-ammonia buffer solution, and stir evenly;

[0075] (2) Put the sample obtained in step (1) on the stirrer immediately, heat for 20 minutes, after the end, use four layers of slow-speed filter paper, add pulp, and filter under reduced pressure; wash 8 times with deionized water, combine the filtrates, and transfer to 100mL volumetric flask, constant volume;

[0076] (3) Pipette 25mL of the solution obtained in step (2) into an Erlenmeyer flask, add 15mL of phosphoric acid, mix well, place on a high-temperature electric furnace to heat, the solution evaporates until phosphoric acid fumes come out, and the temperature is about 220-240°C , stop heating;

[0077] (4) Immediately add 3.0g ammonium nitrate, shake well, let ...

Embodiment 3

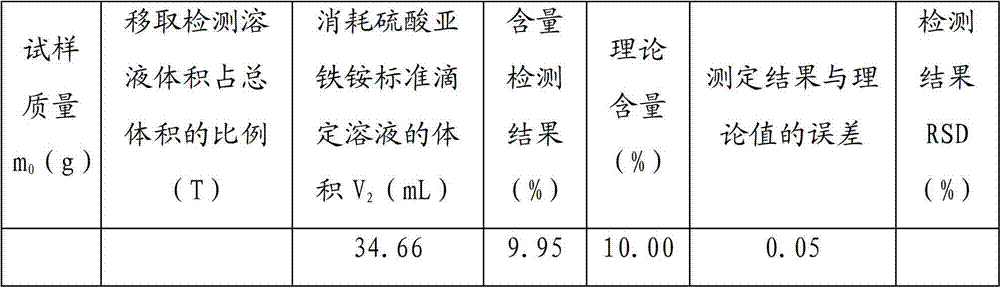

[0090] Mix 0.05g elemental manganese in every 9.95g pure lithium manganese phosphate, detect as sample, comprise the following steps:

[0091] (1) Weigh 15.56g of the sample into a conical flask, put it into a stirrer, add 60mL of phosphate buffer (pH7.6), and stir evenly;

[0092] (2) Put the sample obtained in step (1) on the stirrer immediately and heat it for 10 minutes. 100mL volumetric flask, constant volume;

[0093] (3) Pipette 25mL of the solution obtained in step (2) into an Erlenmeyer flask, add 15mL of phosphoric acid, mix well, place on a high-temperature electric furnace to heat, the solution evaporates until phosphoric acid fumes come out, and the temperature is about 220-240°C , stop heating;

[0094] (4) Immediately add 2.0g ammonium nitrate, shake well, let it stand still, remove nitrogen oxides, cool to 50°C, add 60mL deionized water, shake well, continue to cool to room temperature, and then titrate the solution with ferrous ammonium sulfate standard Tit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com