Method for detecting exhaust enthalpy of turbine

A detection method and technology of exhaust steam enthalpy, which can be used in measurement devices, heat measurement, instruments, etc., can solve the problems of large measurement error, no temperature measurement points, and insufficient accuracy of system heat balance calculation results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

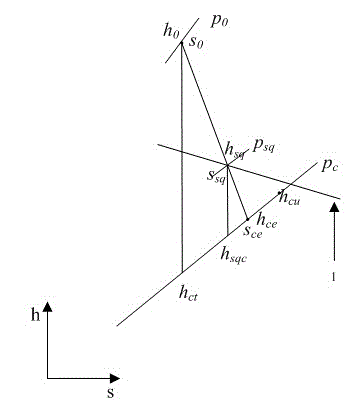

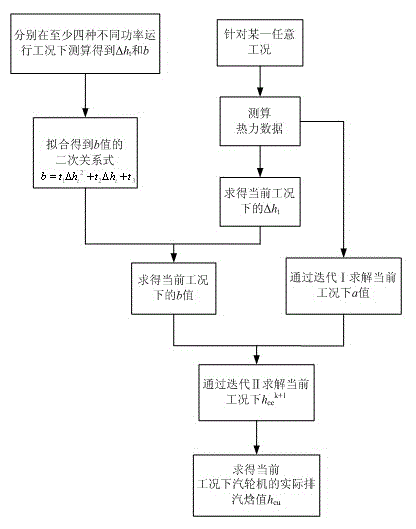

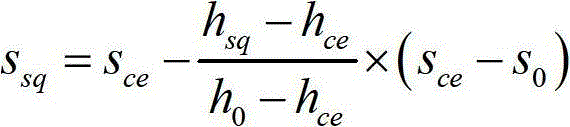

Method used

Image

Examples

Embodiment 1

[0048] Example 1: According to four different working conditions, the exhaust steam enthalpy value of a 300MW steam turbine of SAIC was detected under any working condition.

[0049] 1) In four different power operating conditions: rated working condition (THA working condition), 75% rated working condition (75% THA working condition), 60% rated working condition (60% THA working condition) and 50% rated working condition The ideal enthalpy drop △h of the low-pressure cylinder of the steam turbine is measured and calculated under the working condition (50%THA working condition) t And the percentage b of the sum of nozzle loss, rotor blade loss, blade height loss, sector loss, impeller friction loss, and leakage loss of the low-pressure cylinder accounted for the ideal enthalpy drop of the low-pressure cylinder b, to obtain the △h under each working condition t and b, the estimated △h t The methods for value and b-value are as follows:

[0050] 11) Use the temperature and pre...

Embodiment 2

[0078] Example 2: According to five different working conditions, the exhaust steam enthalpy value of a certain 300MW steam turbine of SAIC was detected under any working condition.

[0079] 1) In five different power operating conditions: rated working condition (THA working condition), maximum continuous output (TMCR working condition), 75% rated working condition (75% THA working condition), 60% rated working condition (60 %THA working condition) and 50% rated working condition (50%THA working condition), the ideal enthalpy drop △h of the low-pressure cylinder of the steam turbine is calculated t And the percentage b of the sum of nozzle loss, rotor blade loss, blade height loss, sector loss, impeller friction loss, and leakage loss of the low-pressure cylinder accounted for the ideal enthalpy drop of the low-pressure cylinder b, to obtain the △h under each working condition t and b, the estimated △h t The methods for value and b-value are as follows:

[0080] 11) Use the...

Embodiment 3

[0103] Example 3: According to six different working conditions, the exhaust steam enthalpy value of a certain 300MW steam turbine of SAIC was detected under any working condition.

[0104] 1) In six different power operating conditions: rated working condition (THA working condition), maximum continuous output (TMCR working condition), summer working condition (TRL working condition), 75% rated working condition (75%THA working condition ), 60% rated working condition (60%THA working condition) and 50% rated working condition (50%THA working condition), the ideal enthalpy drop △h of the low-pressure cylinder of the steam turbine is calculated t And the percentage b of the sum of nozzle loss, rotor blade loss, blade height loss, sector loss, impeller friction loss, and leakage loss of the low-pressure cylinder accounted for the ideal enthalpy drop of the low-pressure cylinder b, to obtain the △h under each working condition t and b, the estimated △h t The methods for value an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com