Water-saving control valve of resistance welding piston rod cooling system

A cooling system and resistance welding technology, applied in resistance welding equipment, sliding valves, valve devices, etc., can solve the problems of oil leakage and scrapping of shock absorbers, reduction of hardness of chrome plating layer, scratching of rubber oil seals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

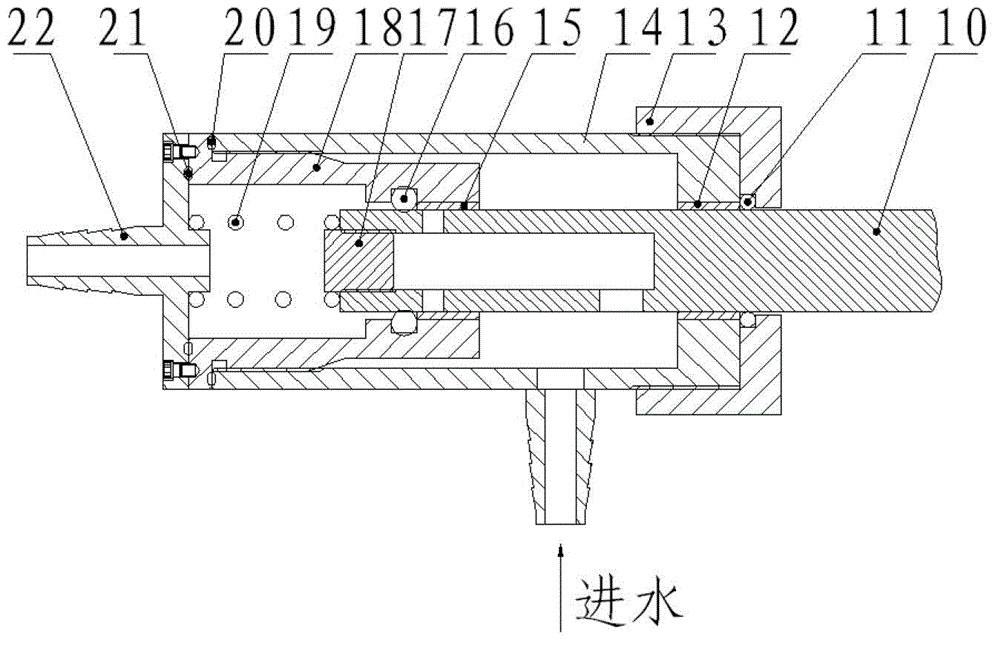

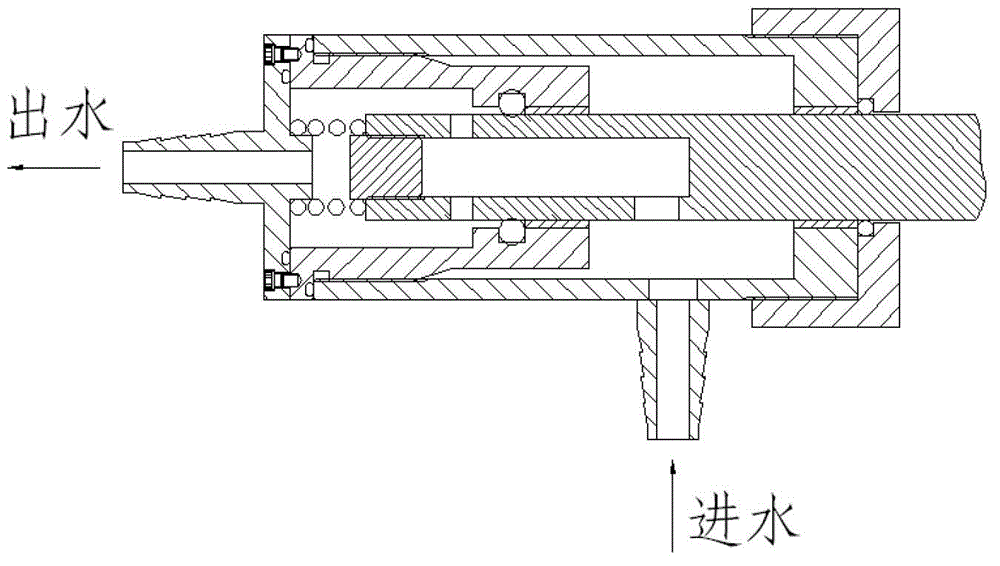

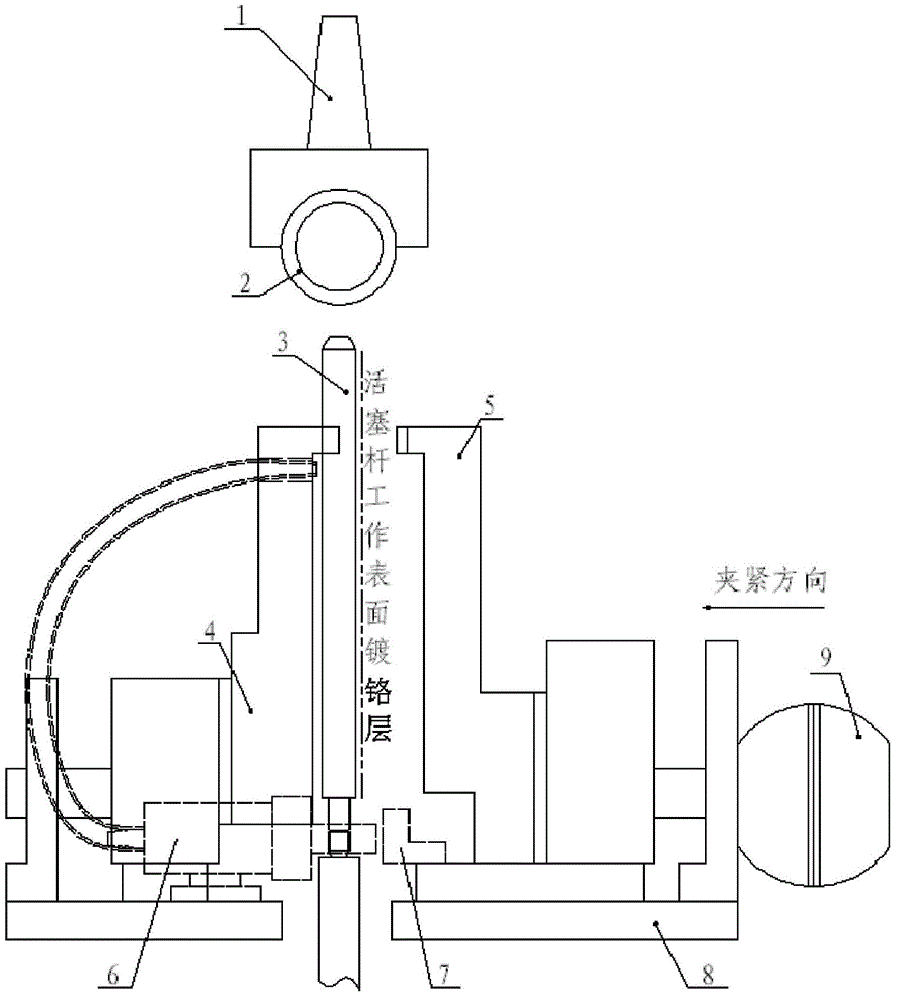

[0015] attached by figure 1 It can be seen that the present invention includes a cylinder body 14 and a guide support 18 provided in the cylinder body 14, and also includes a guide column switch 10, and the guide column switch 10 is arranged in the guide support 18, and the cylinder body 14 and the guide column The junction between the support 18 and the guide post switch 10 is provided with a front guide cylinder 12 and a rear guide cylinder 15, and two different cavities are formed between the cylinder body 14 and the guide post switch 10 and the guide support 18 and the guide post switch 10. Body, the cavity between the guide support 18 and the guide post switch 41 is provided with a return spring 19 . A long hole is drilled in the axial center of the guide column switch 10, and two rows of holes communicating with the axial long holes are drilled on the surface, and a sealing bolt 17 is provided at the starting end of the axial long hole. The end of the cylinder body 14 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com