Embedded nut used for stone cellular board

A technology of stone honeycomb panels and pre-embedded nuts, which is applied in the direction of nuts, bolts, threaded fasteners, etc., can solve the problems of unstable installation, and achieve the effect of fast and firm installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

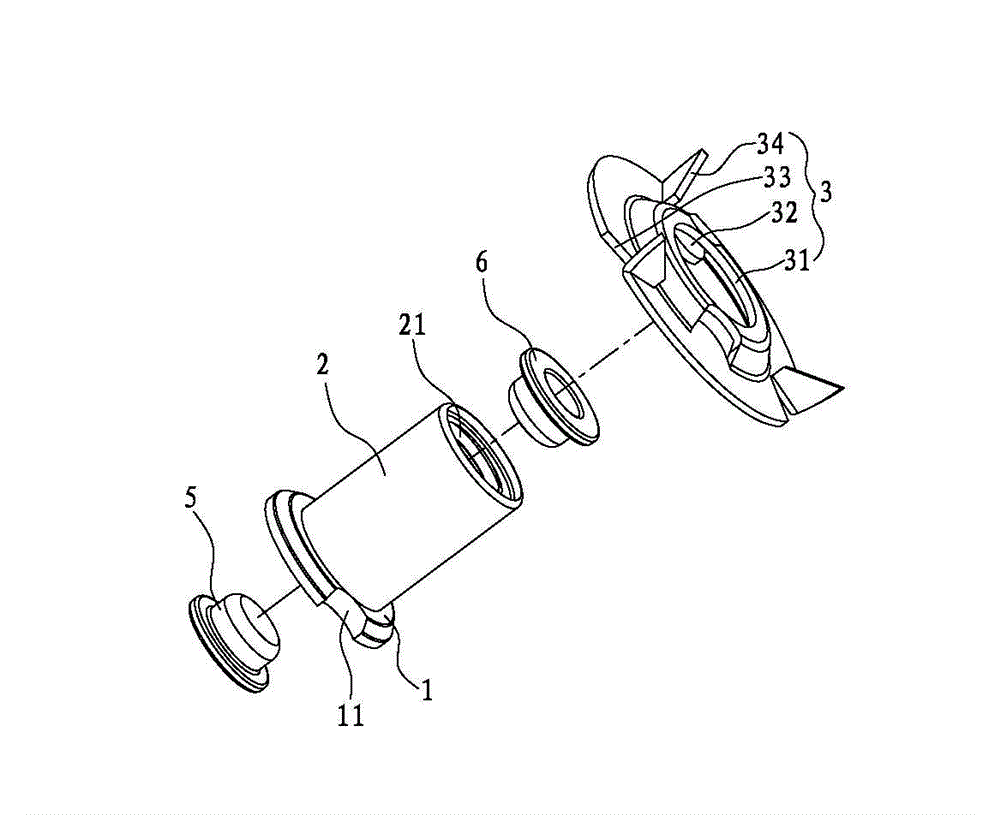

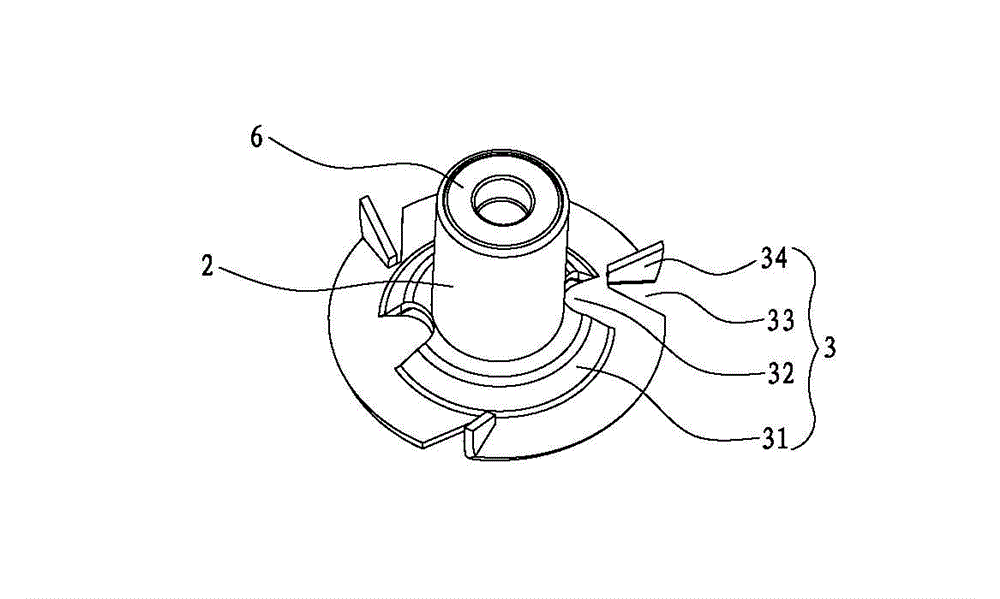

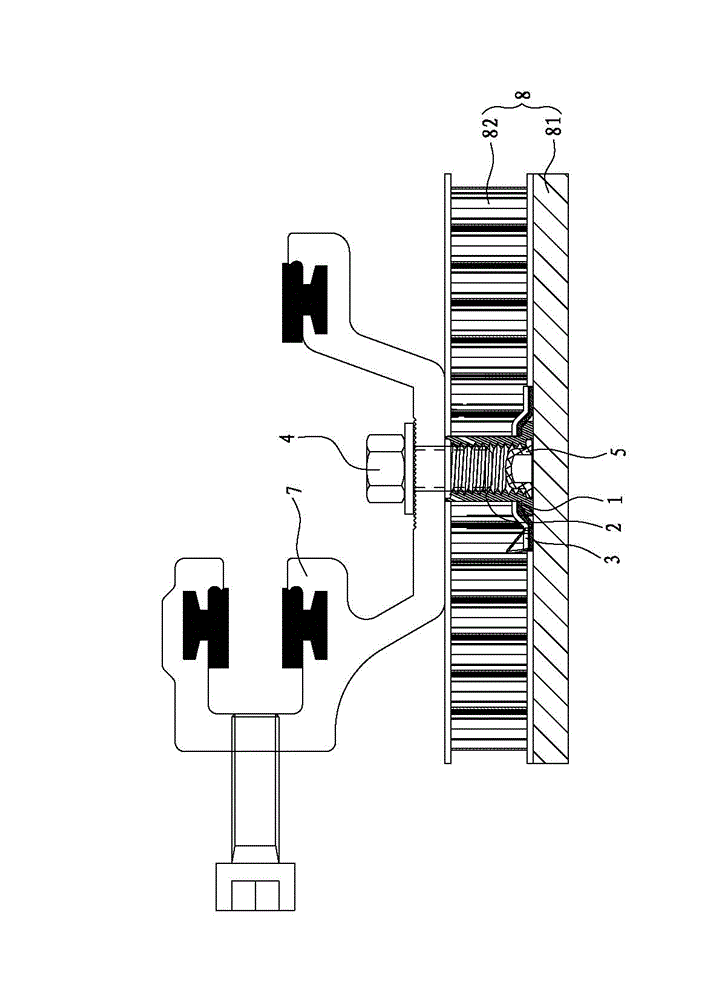

[0037] Such as figure 1 , figure 2 and image 3 Shown is a preferred embodiment of the present invention, an embedded nut for a stone honeycomb panel, including a cylinder 2 with a base 1 and an anti-rotation ring 3 . The base 1 is connected with the inner end of the cylinder 2, and the cylinder 2 forms an internally threaded hole 21. The improvement of the present invention is that the anti-rotation ring 3 is sleeved on the cylinder 2 , the anti-rotation ring 3 is positioned on the base 1 , and an upturned angle 34 is formed on the anti-rotation ring 3 . The anti-rotation ring 3 of the present invention can be fixed in the stone honeycomb panel 8 together with the cylinder 2 and the base 1, and snapped into the honeycomb panel 82 by means of the upturned angle 34, effectively preventing the entire embedded nut from being stuck in the stone honeycomb panel 8 Rotate so that the present invention will not be driven to rotate together when screwing and cooperating with the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com