Anti-oil back streaming structure of vacuum pump

A vacuum pump and anti-return technology, which is applied to the components of the pumping device for elastic fluid, pump elements, rotary piston type/swing piston type pump components, etc., can solve the problem that the vacuum pump cannot be started or is difficult to start, and the exhaust of the vacuum pump Problems such as large resistance, vacuum pump failure and scrapping, etc., achieve the effect of simplifying product structure design, ensuring smooth operation, and solving startup difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

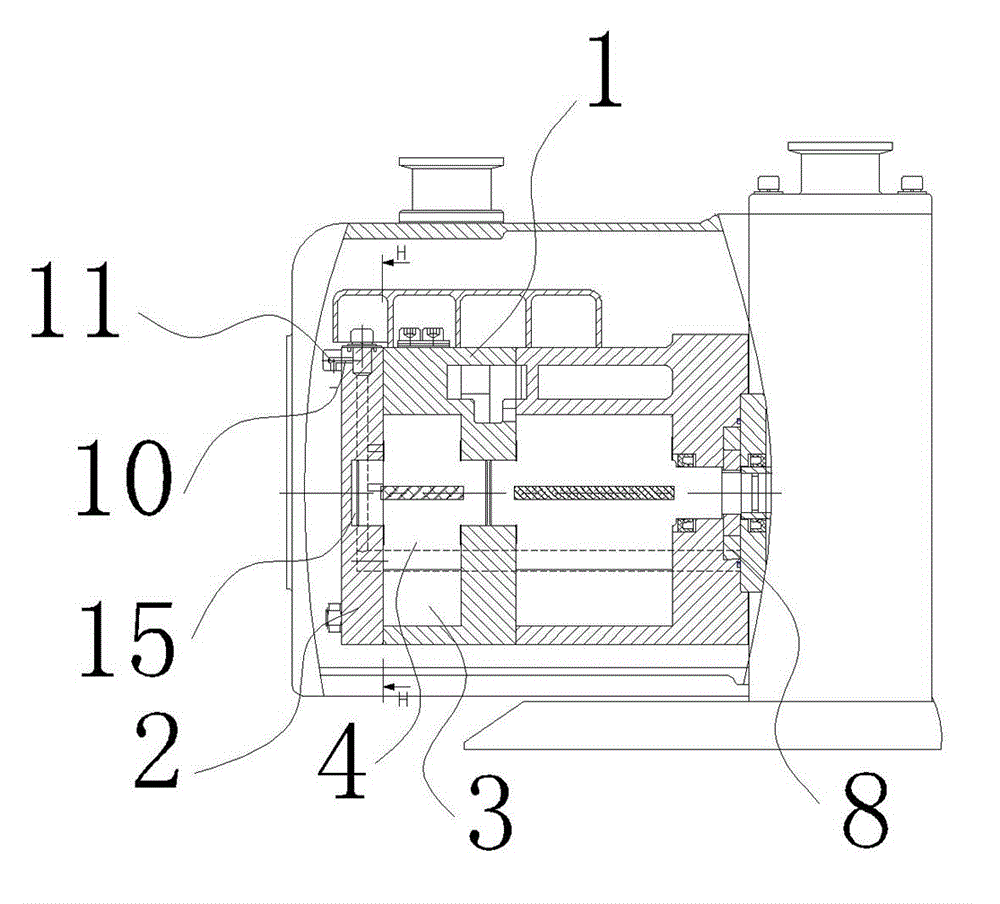

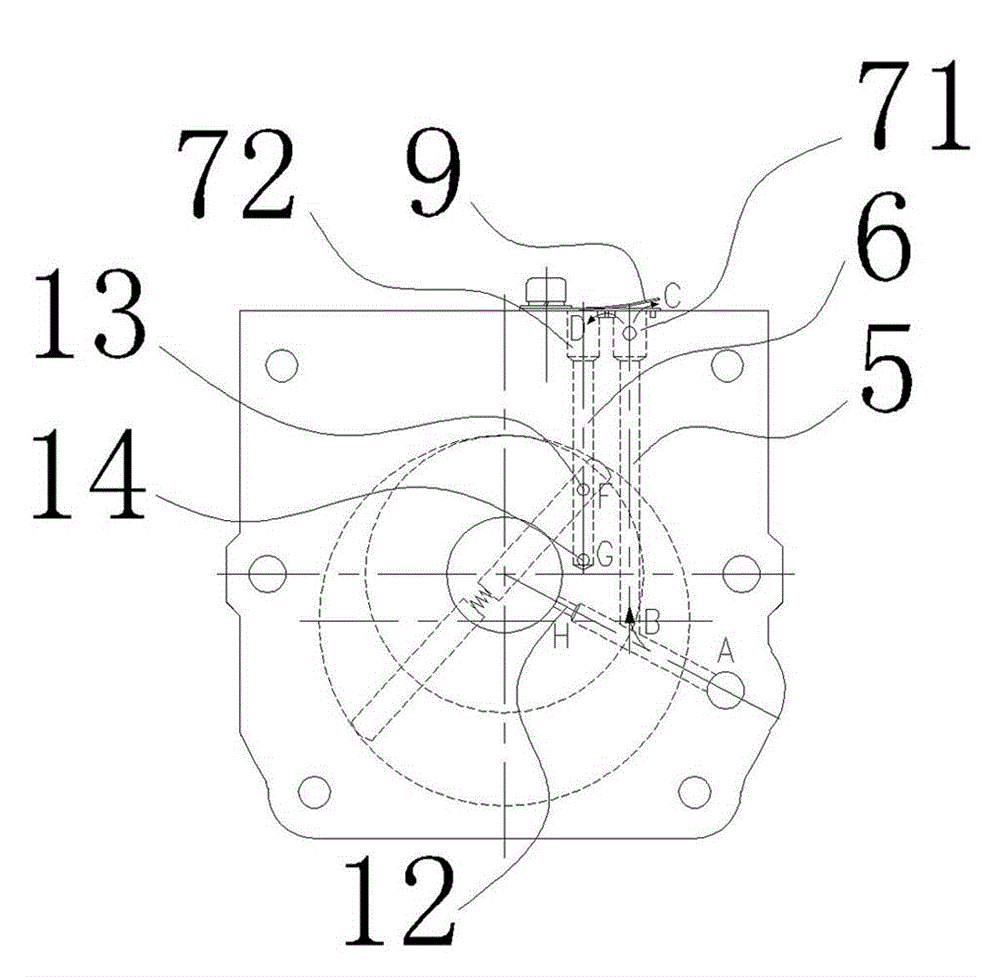

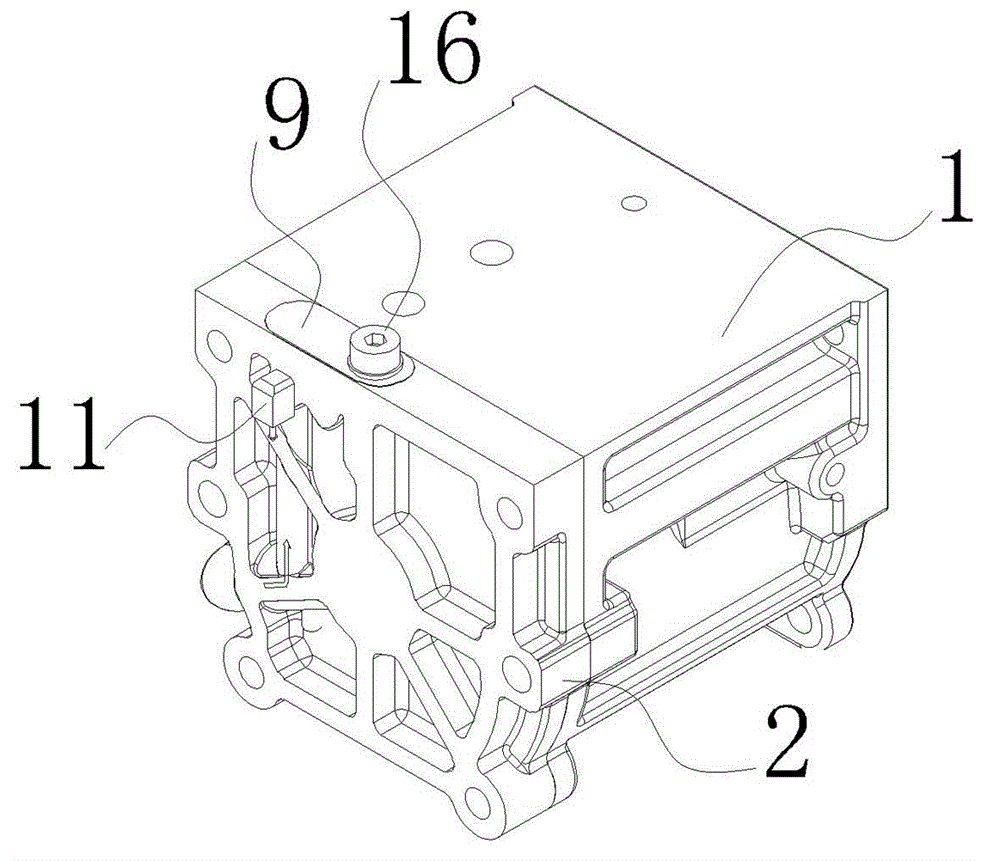

[0024] Such as figure 1 As shown, in order to clearly describe the anti-oil return structure of a vacuum pump of the present invention, the following is an example of a two-stage rotary vane vacuum pump. It includes a pump stator 1 and a pump back cover 2 packaged at the rear end of the pump stator 1. A pump rotor 4 is eccentrically arranged in the pump housing cavity 3 formed by the pump stator 1 and the pump back cover 2, and a rotating shaft positioning hole 15 of the pump rotor 4 is opened on the inner side of the pump rear cover 2, and the positioning hole 15 is connected with the rotating shaft positioning hole. 15 The opposite pump stator 1 is provided with a stator rotating shaft positioning hole, and the pump rotor 4 is rotatably supported between the rotating shaft positioning hole 15 and the stator rotating shaft positioning hole, and the two ends of the pump rotor 4 are respectively connected to the inner surface of the pump back cover 2 and the pump The end surfa...

Embodiment 2

[0027] On the air intake side of the pump back cover 2, there is a pump oil outlet passage 5 and a pump oil introduction passage 6 along the longitudinal direction, and the diameter of the lubricating passage 12 is 1 / 2 of the diameter of the pump oil outlet passage 5, and the rest is the same as that of the implementation Example 1 is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com