Construction method of grouting to repair leaks in the joints of ground-connected walls

A construction method and joint technology, which are applied in artificial islands, sheet pile walls, water conservancy projects, etc., can solve the problems that grouting steel pipes cannot be recycled and reused, and the consumption of steel pipes is large. Simple and saving machining effort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Further illustrate the present invention below in conjunction with embodiment and accompanying drawing.

[0031] The construction method of grouting leakage repair of the present invention is carried out when constructing the middle width of the ground connecting wall, and specifically comprises the following steps:

[0032] step 1:

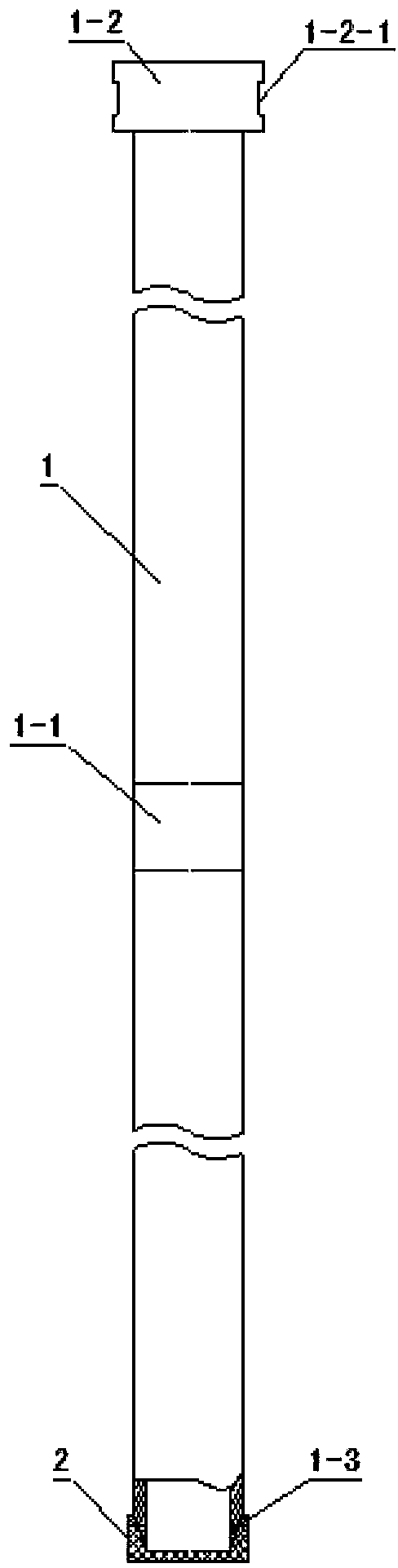

[0033] prepared as figure 1 The mold core drawing pipe 1 that reserves the grouting channel at the joint of the groove section wall as shown.

[0034] Such as figure 1 As shown, the core drawing tube 1 is a circular seamless steel pipe with extrusion resistance, bending resistance and smooth surface, the outer diameter is 50-60 mm, and the length should be greater than the wall of the groove section, that is, the design height of the middle width is 30-50 mm. When the mold core drawing pipe needs to be connected by seamless steel pipe, the two ends of the pipe joint 1-1 can be threadedly connected with the inner side of the seamless st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com