Raw material dry-state proportion and preparation vulcanization process of latex for producing low-nitrosamine condom

A nitrosamine and condom technology, applied in male contraceptives, etc., can solve the problem that the safety risk residue of chemical cleaning has not been fully evaluated and verified, and achieve the effect of reducing the risk of carcinogenicity and using it safely and reliably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

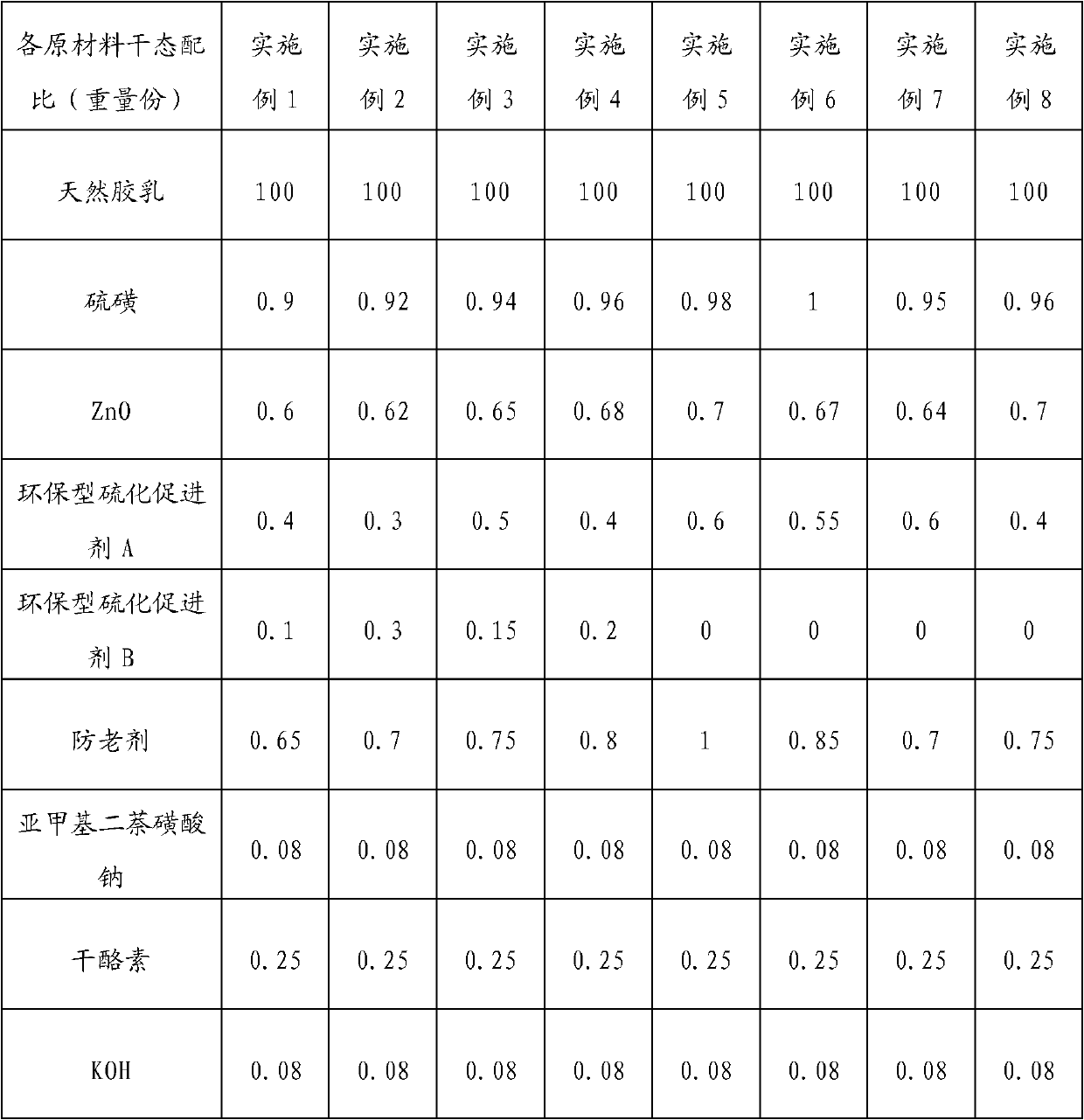

[0032] A preparation and vulcanization process of latex for low-nitrosamine condom production, comprising the following steps:

[0033] (1) Take the specified raw materials in parts by weight in the following table 1 respectively, and prepare an aqueous solution or an emulsion dispersed in water, and the mass percent concentration is respectively: natural rubber latex-60%, sulfur-50%, ZnO-50% , Environment-friendly vulcanization accelerator A-50%, environment-friendly vulcanization accelerator B-50%, anti-aging agent-40%, KOH-10%, casein-10%, sodium methylene dinaphthalene sulfonate-10%, Among them, the environment-friendly vulcanization accelerator A uses zinc dibenzyl dithiocarbamate, the environment-friendly vulcanization accelerator B uses tetrabenzyl thiuram disulfide, and the anti-aging agent uses 2,6-di-tert-butyl-4-methanol base phenol;

[0034] (2) adding the natural rubber latex emulsion prepared according to step (1) in the vulcanization tank;

[0035] (3) Ammonia s...

Embodiment 2

[0045] The specified raw materials are weighed in the following table 1 to repeat the method of Example 1, wherein the environment-friendly vulcanization accelerator A selects zinc diisobutyldithiocarbamate for use, and the environment-friendly vulcanization accelerator B selects tetrabenzyl Thiuram disulfide and anti-aging agent are selected from 2,6-di-tert-butyl-4-methylphenol.

Embodiment 3

[0047] The specified raw materials are weighed to repeat the method of Example 1 in parts by weight in the following table 1, wherein the environment-friendly vulcanization accelerator A selects dibutyl zinc dithioformate for use, and the environment-friendly vulcanization accelerator B selects tetraisobutyl dithioformate zinc for use. Thiuram sulfide and anti-aging agent are p-cresol and dicyclopentadiene butylated products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com