Process for co-producing functional bio-organic fertilizer and plant fibers by using corn straws

A bio-organic fertilizer and corn straw technology, which is applied in the preparation of organic fertilizers, the treatment of bio-organic parts, organic fertilizers, etc., can solve the problems of comprehensive utilization of straws, limited actual utilization prospects, and insignificant benefits. Conducive to plant absorption, high value, and the effect of product diversification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 A kind of technology that utilizes corn stalks to produce functional bio-organic fertilizer and co-produce plant fiber

[0030] Proceed as follows:

[0031] (1) Detachment of corn stalk leaf skin: use conventional simple mechanical equipment to separate the stalk of corn stalk from the leaf skin. The width is less than 0.8cm, and it is ready for use;

[0032] (2) Cutting: cutting off the above-mentioned corn stalks from which the leaf bark has been removed, and cutting them into fragments with a length of 5 ± 1 cm, and the equipment used is a general grass cutter;

[0033] (3) Expansion and dissociation: Use a high-efficiency expansion cracker to expand and dissociate the above-mentioned cut corn stalks to obtain puffed materials; the expansion temperature is 200°C, and the expansion pressure is 18kg / cm 2 , the puffing time is 18 seconds;

[0034] (4) Screening and separation: Screen the above-mentioned puffed materials: use a 30-mesh steel mesh screen t...

Embodiment 2

[0049] Embodiment 2 A kind of technology utilizing corn stalk to produce functional bio-organic fertilizer and co-producing plant fiber

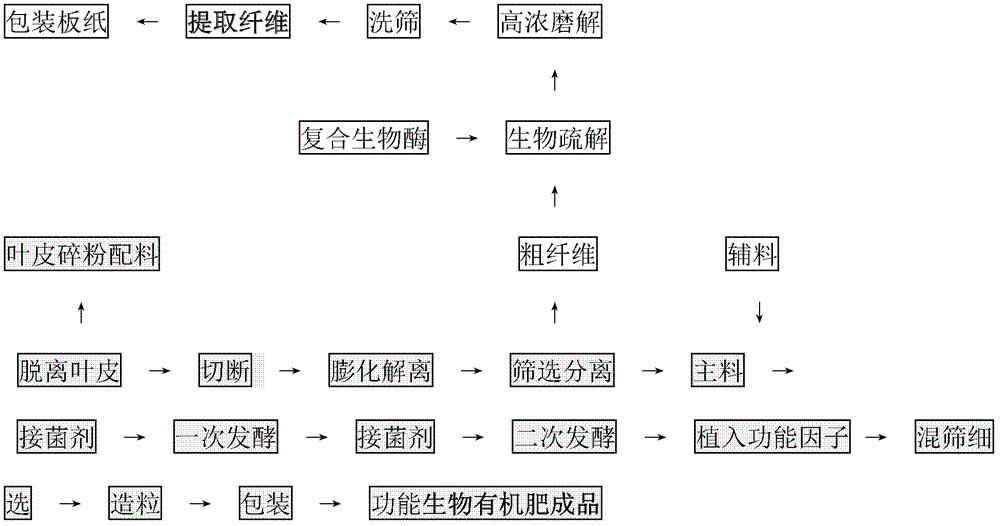

[0050] The steps are as follows: the flow chart is as follows figure 1 shown

[0051] (1) Detachment of corn stalk leaf skin: use conventional simple mechanical equipment to separate the stalk of corn stalk from the leaf skin. The width is less than 0.8cm, and it is ready for use;

[0052] (2) Cutting: cutting off the above-mentioned corn stalks from which the leaf bark has been removed, and cutting them into fragments with a length of 5 ± 1 cm, and the equipment used is a general grass cutter;

[0053] (3) Puffing and dissociation: Use a high-efficiency puffing cracker to puff and dissociate the above-mentioned cut corn stalks to obtain puffed materials; the puffing temperature is 220°C, and the puffing pressure is 20kg / cm 2 , the puffing time is 20 seconds;

[0054] (4) Screening and separation: Screen the above-mentioned puffed materi...

Embodiment 3

[0064] Embodiment 3 A kind of technology that utilizes corn stalks to produce functional bio-organic fertilizer and co-produce plant fiber

[0065] Proceed as follows:

[0066] (1) Detachment of corn stalk leaf skin: use conventional simple mechanical equipment to separate the stalk of corn stalk from the leaf skin. The width is less than 0.8cm, and it is ready for use;

[0067] (2) Cutting: cutting off the above-mentioned corn stalks from which the leaf bark has been removed, and cutting them into fragments with a length of 5 ± 1 cm, and the equipment used is a general grass cutter;

[0068] (3) Puffing and dissociation: Use a high-efficiency puffing cracker to puff and dissociate the above-mentioned cut corn stalks to obtain puffed materials; the puffing temperature is 180°C, and the puffing pressure is 15kg / cm 2 , the puffing time is 15 seconds;

[0069] (4) Screening and separation: Screen the above-mentioned puffed materials: use a 30-40 mesh steel mesh screen for scre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com