Linearly reciprocating hydraulic drive mechanism

A technology of linear reciprocating motion and driving mechanism, which is applied in the direction of conveyors, mechanical conveyors, transportation and packaging, etc. It can solve the problems of increasing manufacturing costs, declining comprehensive economic indicators of machine tools, lengthening machine tools, etc., and achieves volume reduction and transmission structure. Simple and reliable, the effect of increasing the moving distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

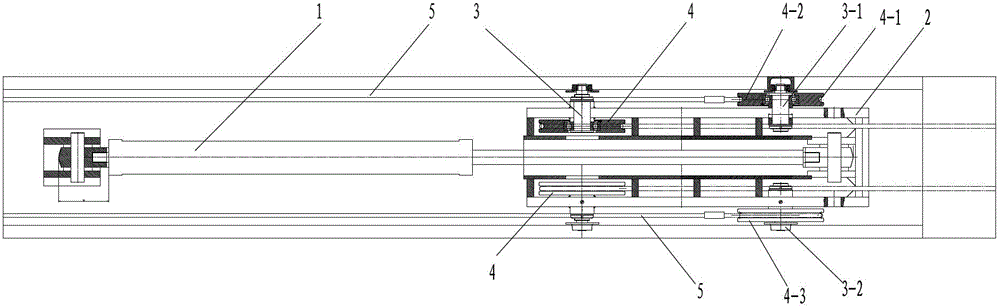

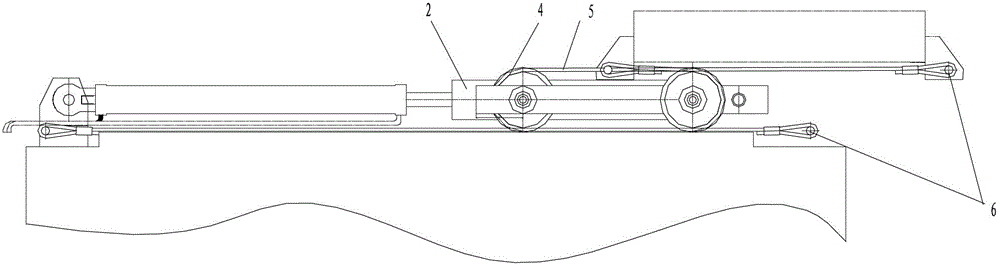

[0013] A hydraulic drive mechanism with linear reciprocating motion. The trolley is driven by a hydraulic cylinder. The left support shaft 3-1 and the right support shaft 3-2 are installed on the left and right sides of the drive trolley. The left support shaft is equipped with a circumferential belt. The left side round wheel 4-2 of circular groove, the right side round round wheel 4-3 that circumference has round groove is housed on the right support shaft, totally four round wheels with the same diameter, two left side round round wheels The round wheel and the two right side circular round wheels all have one on the inside of the mobile frame, and the other round wheel is on the outside of the mobile frame. The left circular wheel is in contact with the right steel wire rope, the right circular wheel is in contact with the left steel wire rope, and the right circular wheel is in contact with the left steel wire rope. There are four steel wire ropes in total. on the fixed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com