Grain die and manufacturing method thereof and granulator

A pellet machine and pellet technology, applied in manufacturing tools, presses, presses for material forming, etc., can solve the problems of affecting output, large running resistance of pressure rollers, useless power consumption, etc., to increase output and eliminate dead ends of rolling. , the effect of reducing useless power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples cited are only used to explain the present invention, and are not used to limit the scope of the present invention.

[0034] The particle mold includes a ring mold and a flat mold. The following describes the present invention with a ring mold and a flat mold as examples.

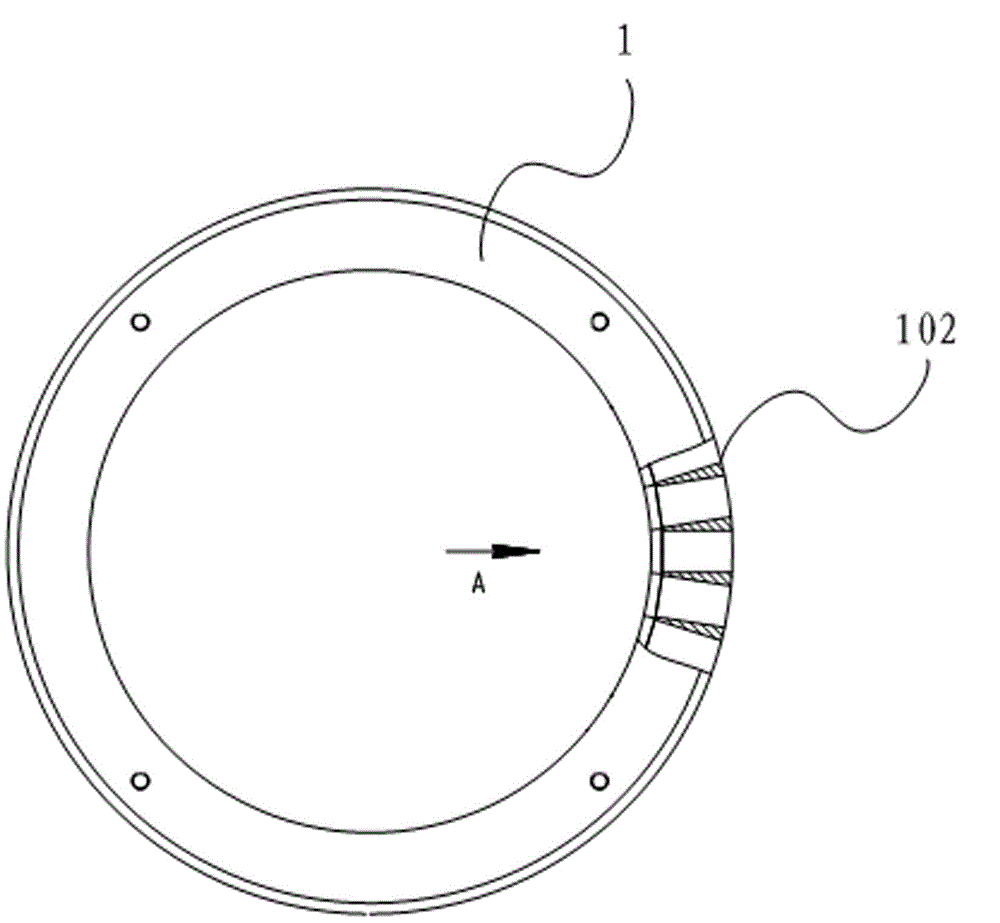

[0035] figure 1 Shown is a schematic diagram of the structure of ring die 1, one of the particle dies. The ring die 1 has a cylindrical structure, and a die hole 102 that leads from the inside of the ring die 1 to the outside is provided on the wall of the ring die 1.

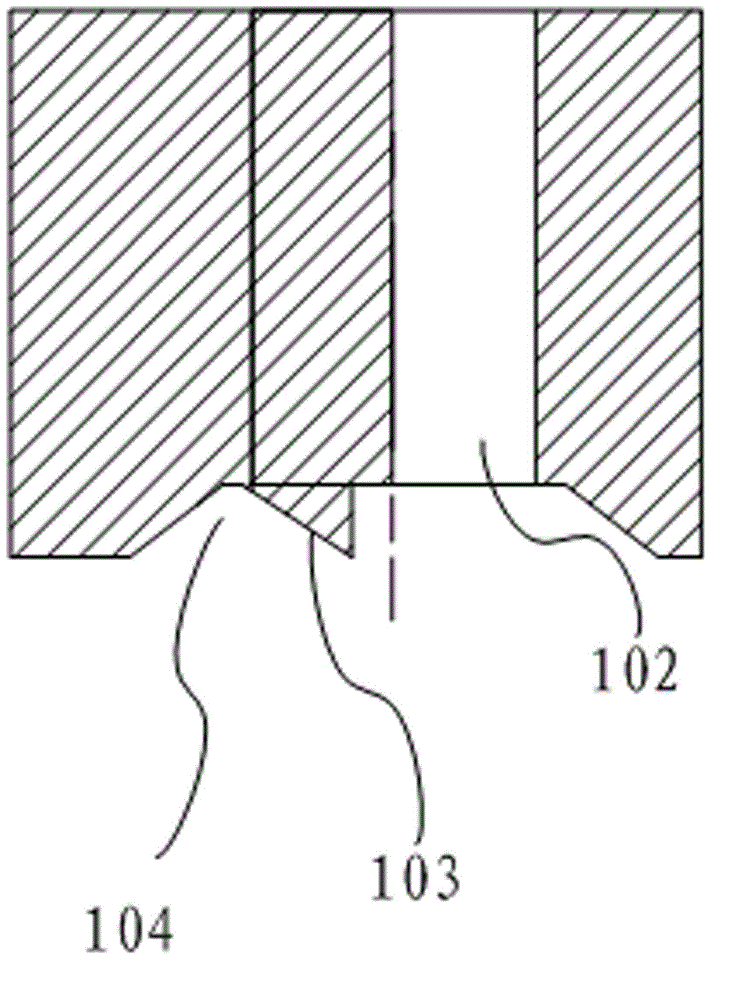

[0036] figure 2 for figure 1 The structure diagram of the ring die 1 in the A direction, image 3 for figure 2 Schematic diagram of the cross-sectional structure of the middle edge B-B. Combine figure 2 with image 3 As shown, on the inner wall of the ring die 1, protrusions 103 are formed inclined to bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com