Wet-type desulfurizing deduster downstream spraying structure

A technology of wet desulfurization and dust collector, applied in chemical instruments and methods, using liquid separating agent, combined devices, etc., can solve the problems of increasing fan motor power and increasing the overall operation resistance of equipment, so as to reduce motor power and reduce equipment resistance , the effect of low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing:

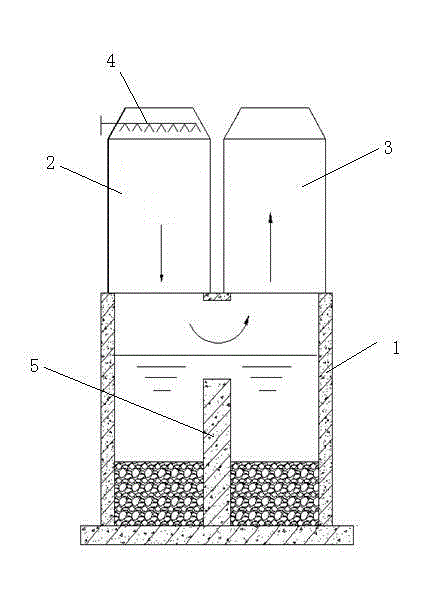

[0011] as attached figure 1 As shown, the present invention includes a base cylinder 1 on which a desulfurizer cylinder 2 and a dehydrator cylinder 3 are arranged. The diameters of the upper ports of the desulfurizer cylinder 2 and the dehydrator cylinder 3 are both smaller than the diameters of the lower ports, and a spray pipe 4 is provided at the upper port of the desulfurizer cylinder 2 . The foundation cylinder 1 is made of concrete, and a partition plate 5 is arranged inside it.

[0012] Working process of the present invention is as follows:

[0013] The sulfur-containing flue gas enters from the upper end of the desulfurizer barrel 2, fully mixes with the desulfurization liquid sprayed from the spray pipe 4, and then moves from top to bottom. During the downward movement of the desulfurizer barrel 2, the flue gas velocity Slow down, which is beneficial for dust, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com