Electric power conversion device

A power conversion device and current technology, applied in circuit devices, output power conversion devices, electrical components, etc., can solve problems such as IGBT damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A first embodiment of the present invention will be described.

[0050] In Embodiment 1, a delta connection CMC is realized that significantly reduces the volume and weight of a reactor (reactor) as compared with the conventional delta connection CMC.

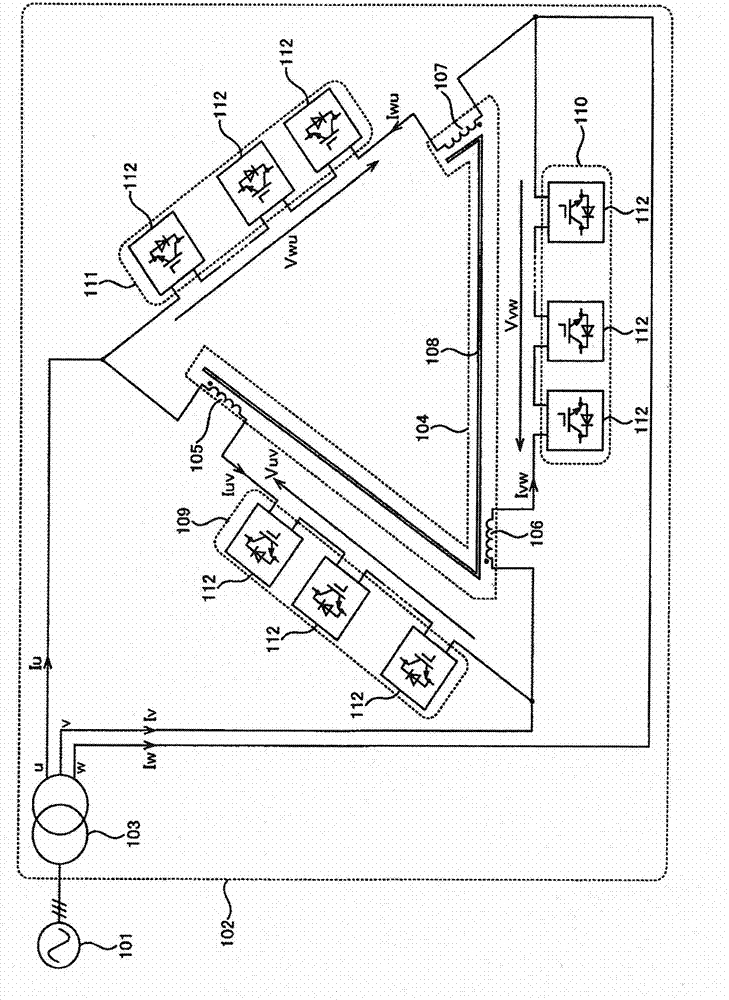

[0051] Below, use figure 1 The overall structure of Example 1 will be described.

[0052] The power conversion device 102 interconnected with the power system 101 is composed of a transformer 103 , a common core reactor 104 , a uv-phase cluster 109 , a vw-phase cluster 110 , and a wu-phase cluster 111 .

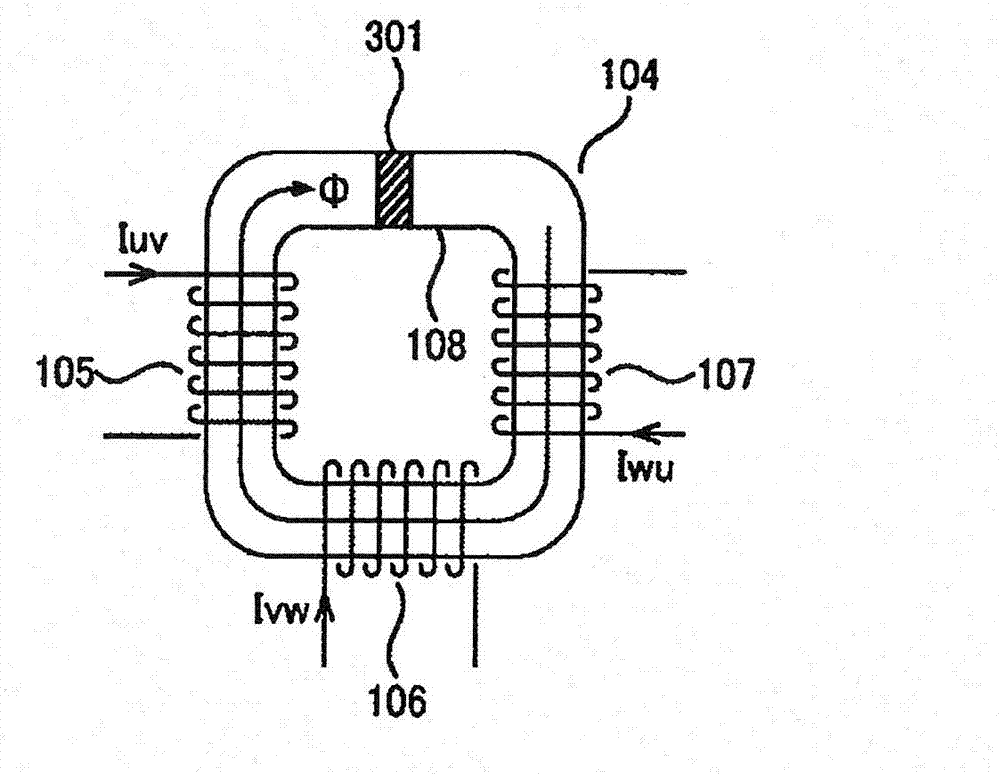

[0053] The common core reactor 104 is composed of uv-phase windings 105, vw-phase windings 106, wu-phase windings 107, and a common iron core 108. The uv, vw, and wu-phase windings 105-107 are polarized with magnetomotive force Wound on the common core 108.

[0054] The uv phase cluster 109 and the uv phase winding 105 are connected in series. Likewise, the vw-phase cluster 110 and the vw-phase winding 106 , and the...

Embodiment 2

[0133] Next, a second embodiment of the present invention will be described.

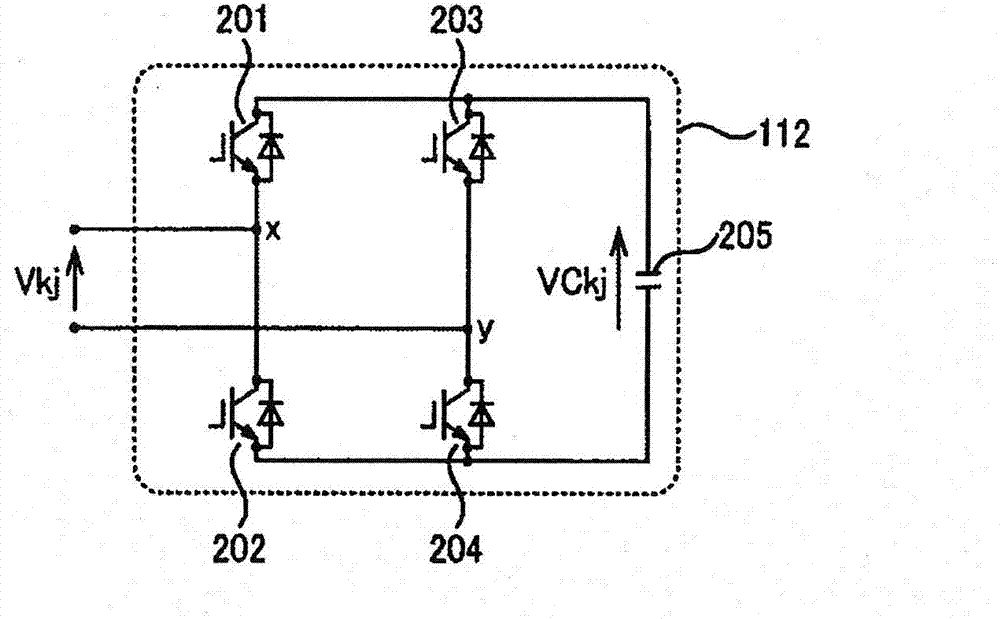

[0134] In Embodiment 2, instead of the unit cell 112 of Embodiment 1 figure 2 ,use Figure 7 A unit cell 701 is shown with an active power supply mechanism 702 connected.

[0135] Thus, in the second embodiment, effective electric power can be received between the power system 101 and the power conversion device 102 .

[0136] Hereinafter, the overall structure of Embodiment 2 will be described.

[0137] In Example 2, in figure 1 In the power conversion device 102 shown, the M unit cells 112 included in each of the clusters 109 to 111 are configured to be figure 2 The unit cell shown is replaced by Figure 7 A unit cell 701 is shown with an active power supply mechanism 702 connected thereto.

[0138] In addition, the whole structure is the same as that of Example 1 except for this point.

[0139] Below, refer to Figure 5 Control when the power conversion device 102 receives active power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com