Metallic target generator without vibrating rod

A metal target and generator technology, which is applied in X-ray tubes with huge currents, microlithography exposure equipment, discharge tubes, etc., can solve the problems of uneven falling track and deviation of metal targets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

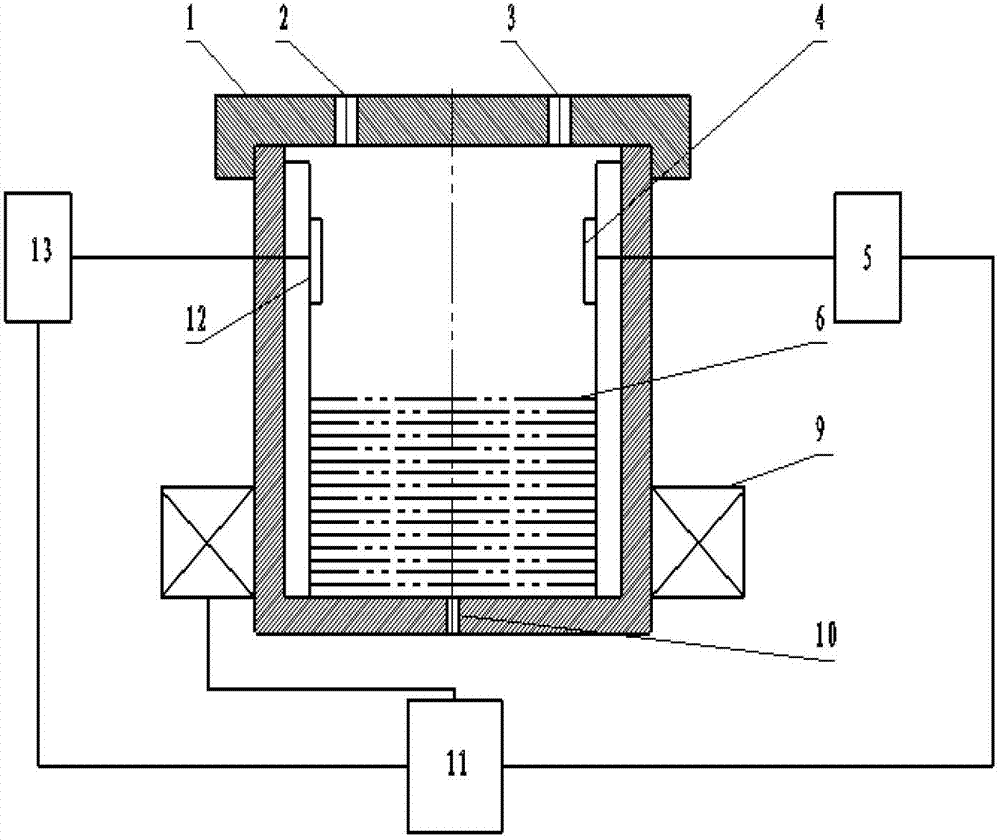

[0057] figure 2 It is a metal target generator without a vibrating rod according to the present embodiment, which includes a cylinder body with an upper cover 1 on the top of the cylinder body, liquid metal 6 is placed in the cylinder body, and a micropore 10 is arranged at the center of the bottom of the cylinder body. The metal liquid drips through the micropores, and an electromagnetic coil 9 is arranged on the outer peripheral wall of the lower part of the cylinder, which generates a changing electromagnetic field by passing in a changing current, and the changing electromagnetic field stirs the liquid metal 6 in the cylinder. , when the liquid metal 6 drops from the micropore 10, it is a metal target that is evenly dropped.

[0058] And the cylinder is also provided with a pressure sensor 12 for detecting the pressure in the cylinder and a temperature sensor 4 for detecting the temperature in the cylinder. The pressure sensor 12 and the temperature sensor 4 are connected...

Embodiment 2

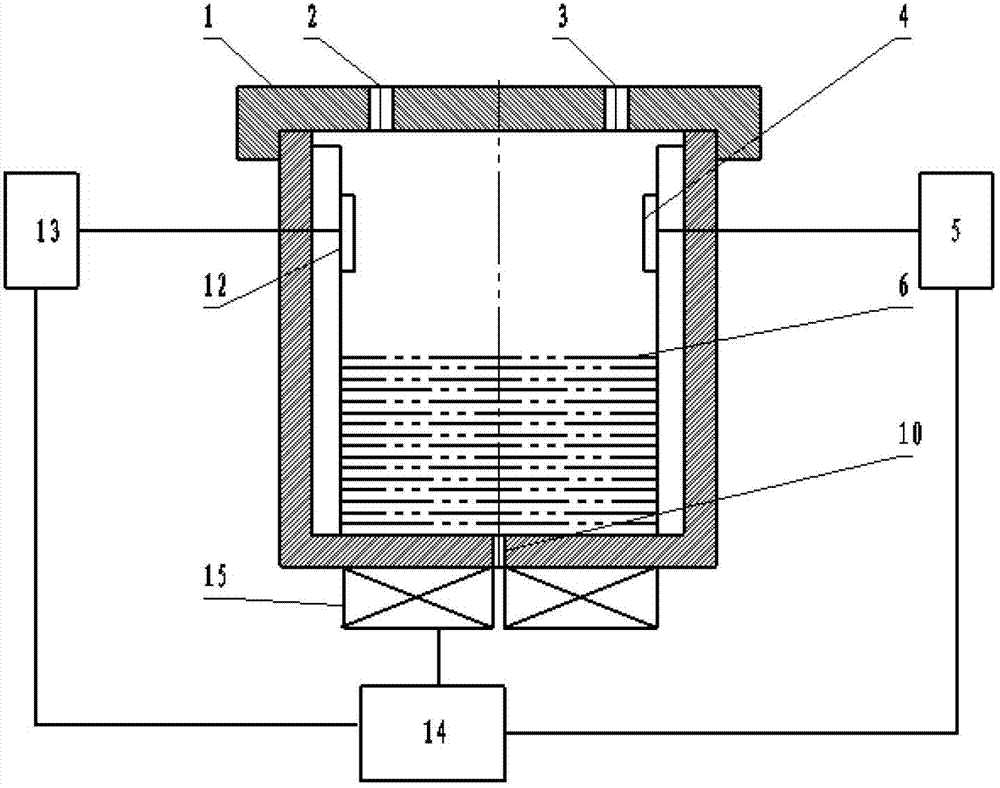

[0072] image 3 It is another kind of electromagnetic stirring current breaking device without a vibrating rod. The difference between this embodiment and Embodiment 1 is that the electromagnetic coil 15 used to generate the driving force for stirring the liquid metal in the cylinder is located at the bottom of the cylinder. When the variable frequency current is input, (similarly) a traveling wave magnetic field will be generated. This magnetic field will pass through the bottom of the container and act on the molten metal, generating induced electric potential and current in the molten liquid. The induced current and the magnetic field will generate electromagnetic Force, so as to promote the directional flow of molten metal and play a stirring role.

[0073] like image 3 As shown, the temperature sensor 4 transmits the measured temperature in the container to the temperature control system 5 to adjust the system temperature. The pressure measured by the pressure sensor 1...

Embodiment 3

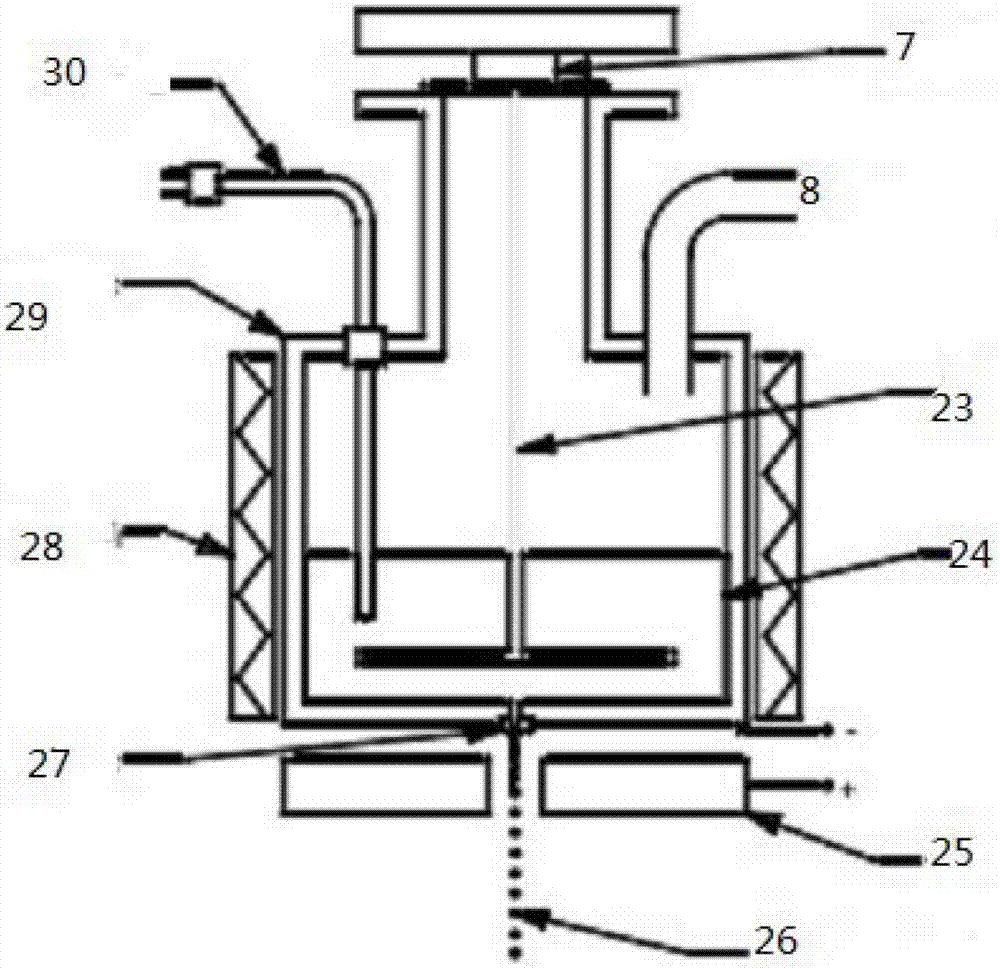

[0075] Image 6 As shown, the micropore 10 in this embodiment protrudes from the bottom of the cylinder and extends outward to form a tubular channel, and the electromagnetic coil 9 is symmetrically arranged on the outer periphery of the protruding hole wall of the micropore channel 10 .

[0076] According to the knowledge of electromagnetism, the molten metal will produce forced flow under the action of the rotating magnetic field, and the flow direction of the flowing metal liquid can be reversed. This device uses this principle to control the frequency of producing metal targets by controlling the closure of the rotating magnetic field. When working, the jet fills the entire micropore, and a rotating magnetic field is applied at the micropore. Since the jet flows downward under pressure control, when the rotating magnetic field is turned on, the jet is subject to a large Lorentz force. This rotational force can make the jet The change of the flow direction has a braking eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com