On-line ultrahigh-voltage line power transformer test method

A technology of power transformers and test methods, which is applied in the direction of measuring electrical variables, instruments, and measuring electricity, can solve problems such as unstable instrument indications, large errors in measurement results, and unreadable readings, so as to achieve true and credible diagnostic results and reduce Measuring errors and preventing static electricity from beating people

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

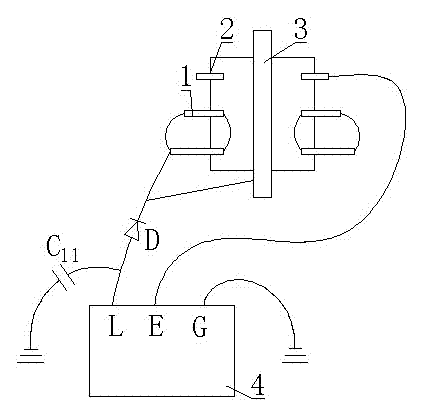

[0035] As shown in the figure, the specific steps of the ultra-high voltage line power transformer test method without disconnection are as follows:

[0036] The specific steps of the ultra-high voltage line power transformer test method without disconnection are as follows:

[0037] 1) Measure the insulation resistance between the transformer core 3, clamps, each winding and the bushing, as well as the leakage current, dielectric loss factor and capacitance value of the bushing and each winding before the transformer is put into operation, and use it as the "original Data", after connecting the side wires of the transformer, measure the above data again as the "basic data".

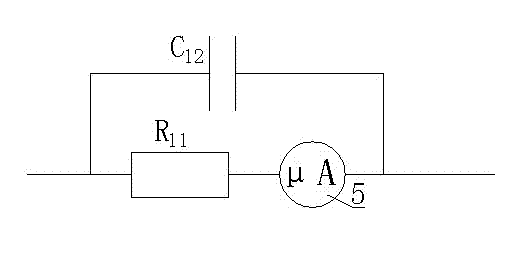

[0038] 2) Measure the insulation resistance R of the winding: ground the G terminal of the megohmmeter 4, connect the L terminal of the megohmmeter 4 with the winding to be tested, the iron core 3 and the clamp of the transformer respectively, and connect the L terminal with the transformer to be tested ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com