Long-life lining type prestressed concrete cylinder pipe subjected to multilayer anti-corrosive treatment

An anti-corrosion treatment, pre-stressed steel technology, applied in the direction of pipeline anti-corrosion/anti-rust protection, pipes, rigid pipes, etc., can solve the problems of steel cylinder corrosion perforation, erosion, corrosive medium erosion, etc., to achieve scientific and reasonable design and overall structure. Simple, easy-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

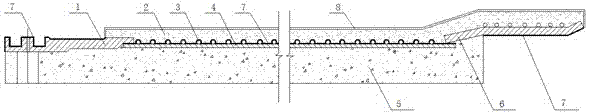

[0022] Such as figure 1 As shown, the lined prestressed steel cylinder concrete pipe with long-life multi-layer anticorrosion treatment includes a cylinder part, and a socket steel ring 6 and a socket steel ring 1 arranged at both ends of the cylinder part. The cylinder part is from the inside to the The outer ones are the concrete layer 5 on the inner wall of the steel cylinder, the steel cylinder 4, the fiber anti-seepage and anti-cracking cement mortar protective layer 2 on the outer wall of the steel cylinder, the outermost epoxy coal tar pitch anti-corrosion layer 8, the outer wall of the steel cylinder 4 and the socket steel ring 6 Prestressed steel wires 3 are wound on them. The outer surface of the steel cylinder 4, the outer surface of the prestressed steel wire 3, the lower surface of the socket steel ring and the upper surface of the socket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com