Waste gas inlet end structure of EGR (Exhaust Gas Recirculation) cooler

一种EGR冷却器、进气端的技术,应用在废气再循环、换热器、换热器外壳等方向,能够解决波纹管隔热管失效等问题,达到提高抗振动性能、降低壁面温度、提高可靠性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

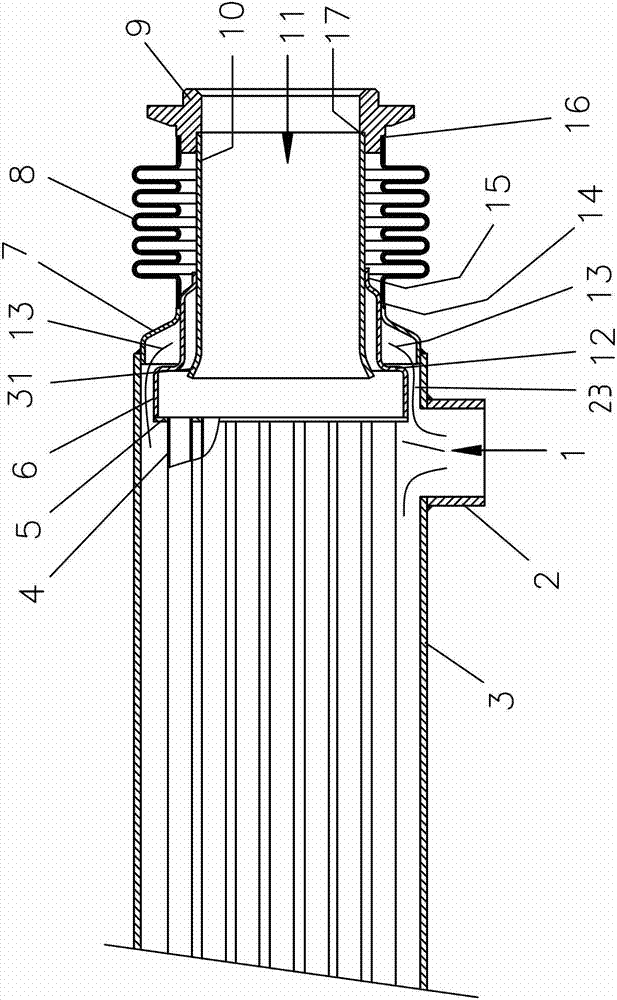

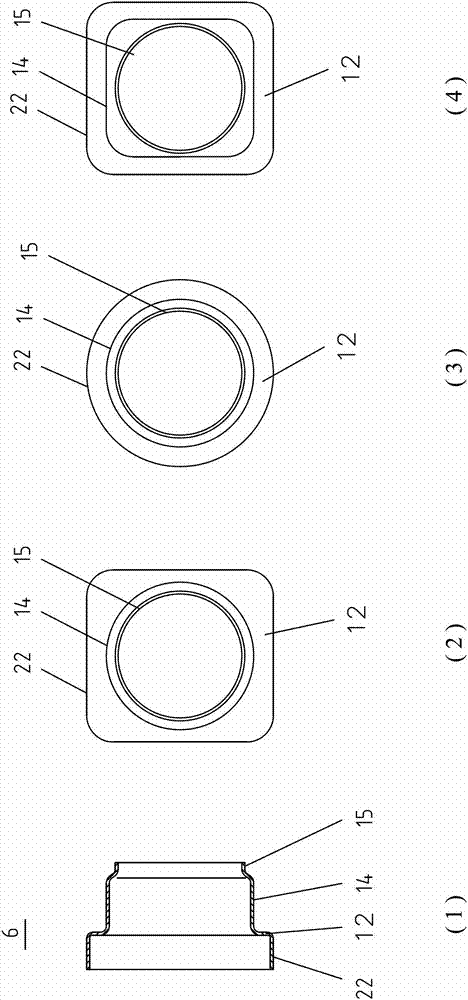

[0024] The present invention will be further described below with specific embodiments in conjunction with the accompanying drawings.

[0025] refer to figure 1 and figure 2 , an exhaust gas inlet structure of an EGR cooler of the present invention, comprising a water housing 3, an air intake pipe 9, a corrugated pipe 8, an insulating pipe 10, an air inlet chamber 6, a pre-cooling water chamber 7 and a main board 5, the described The water casing 3 is provided with a water inlet pipe 2 , and the water casing 3 is provided with a heat dissipation core 4 , and one end of the heat dissipation core 4 is connected with the main board 5 . The air intake pipe 9, the corrugated pipe 8, the pre-cooling water chamber 7 and the water shell 3 are sequentially connected by brazing or argon arc welding. The heat insulation pipe 10 is placed in the bellows 8, one end is welded to the air intake pipe 9, and the other end is suspended. The air intake chamber 6 is a two-stage variable-diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com