Construction method and device for advance support of front probing beam

A technology of advanced support and forward detection beam, which is applied in the direction of supporting the top beam of the mine roof, earthwork drilling and mining, mining equipment, etc. In order to solve problems such as lack of supporting effect, it can achieve the effect of convenient structure acquisition and forward movement, small workload, and enhanced overall supporting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

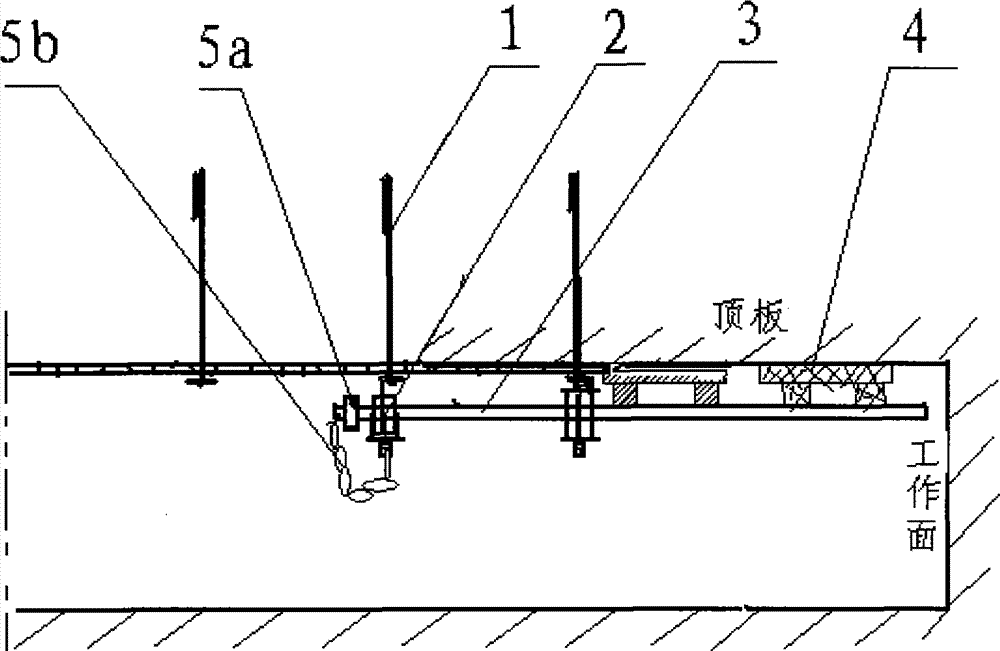

[0019] Such as figure 1 As shown, a kind of advance support construction method of the front probe beam, it is to reserve 30cm-50cm length for the exposed end of the thread of the anchor rod 1 at the top of the roadway when the roadway anchor net is sprayed for a support, so that the thread of the anchor rod 1 The head is exposed to the support surface, and then through the threaded head of the anchor rod 1, install the front and rear two height-adjustable suspension rings 2, insert the front probe beam 3 into the two suspension rings 2, and extend forward to the working On the surface, put a skid 4 in the gap between the front beam 3 and the top plate, adjust the height of the two suspension rings 2, thereby adjusting the angle at which the front beam 3 protrudes, and make the front end of the front beam 3 support the suspended roof; In order to prevent the front beam from slipping, the rear end of the front beam should be provided with a stopper 5a and a hanging chain 5b. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com