Movable bottom plate reinforced concrete support for heaving floor roadway and construction method

A mobile, roadway technology, applied in mine roof support, earthwork drilling, mining equipment, etc., can solve the problems of limited improvement, difficult repair, overall deformation and damage of roadway, etc., and achieve compressive strength and tensile strength improvement. , improve the integrity and carrying capacity, improve the effect of its own carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

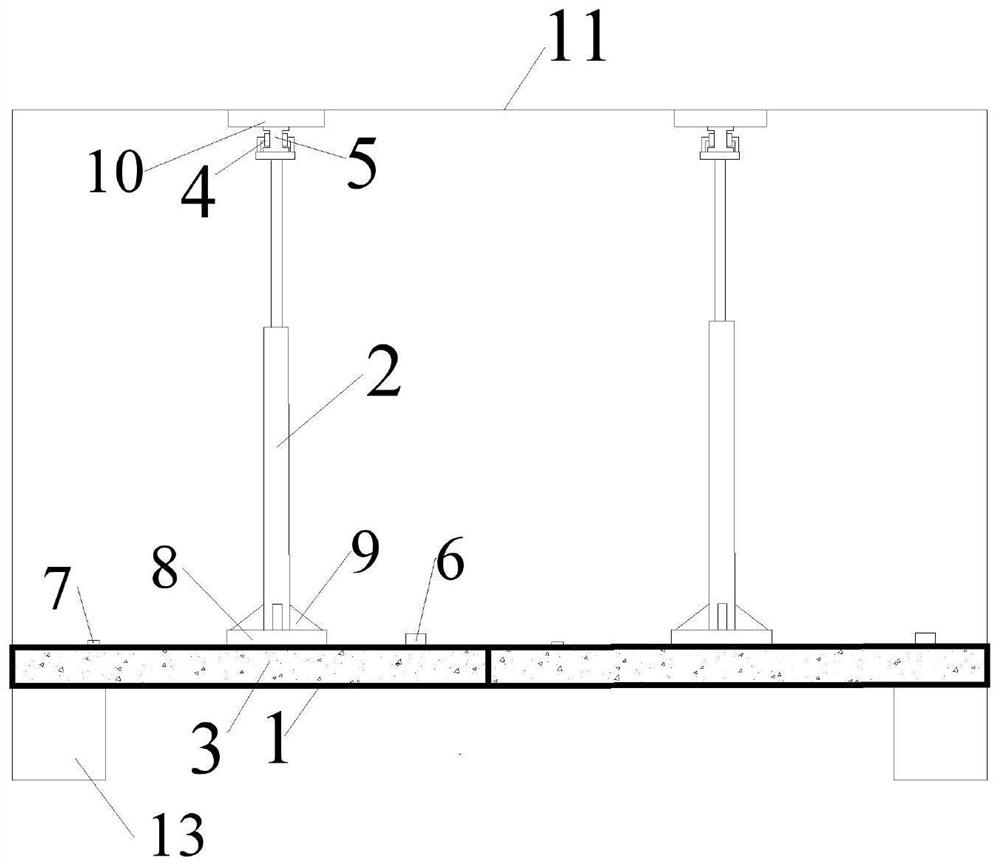

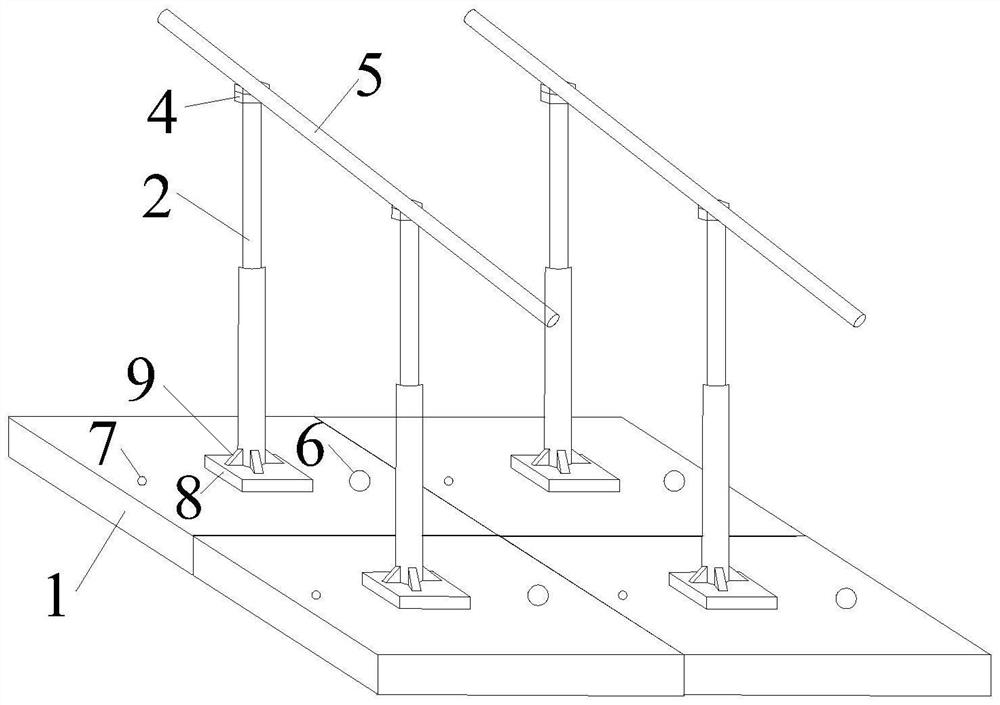

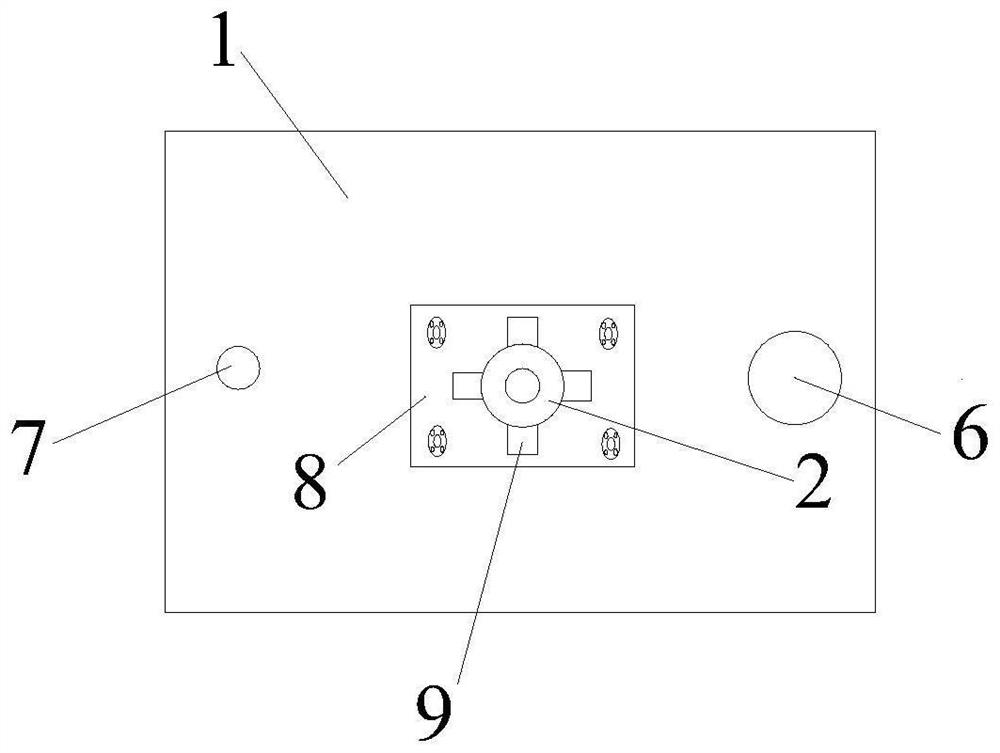

[0033] like Figure 1-5 As shown in the figure, a movable bottom plate steel-concrete support used in a serious kick drum roadway, a hollow steel body 1, a hydraulic support 2, a concrete slurry 3, a fixed slider 4 and a sliding steel rail 5, the hollow steel body (1) It is arranged at the bottom of the roadway 11 , and several hydraulic struts 2 are arranged between the hollow steel body 1 and the top of the roadway 11 . The hollow steel body 1 is a hollow cuboid formed by integral casting of steel with high strength and good toughness, and the edges and corners are chamfered. In this embodiment, the hollow steel body 1 is integrally cast with high-strength and good toughness steel above Q460. , the thickness of the steel is 15-30mm, the length of the hollow steel body 1 is 1-3m, the width is 0.5-1.5m, and the thickness is 0.3-1m. The length, width and thickness of the hollow steel body 1 can be determined according to the size of the mine pressure, Factors such as the dimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com