Mining method for jetting concrete in wet type

A wet spraying and concrete technology, which is used in earth-moving drilling, mining equipment, wellbore lining, etc., can solve the problems of short conveying distance (the horizontal conveying distance is generally not more than 30m, reducing production efficiency, increasing labor intensity and labor volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 A kind of method for mining wet shotcrete:

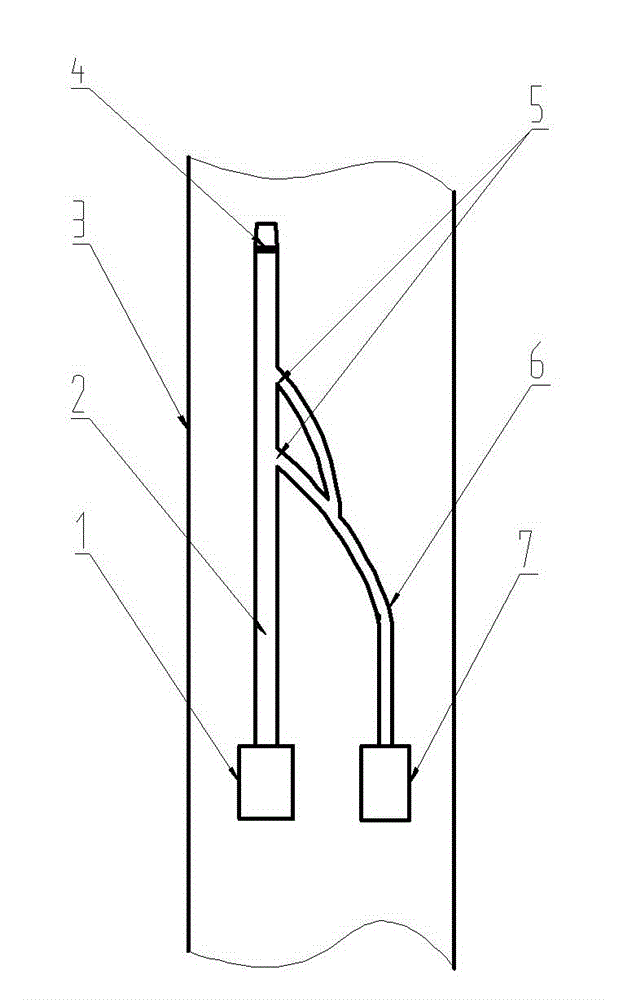

[0027] Utilize the cement slurry conveying equipment 7 to make the cement into uniform cement slurry according to the water-cement ratio 0.6, then transport the cement slurry to the cement slurry delivery pipeline 6, and the length of the delivery pipeline is 80m; the fineness modulus of 2.5 Medium-coarse sand and stone aggregates with a particle size of ≤15mm (the sand and gravel should be washed with clean water before use) are formulated into a mixture at a weight ratio of 1:1, and the sand and gravel mixture is transported to the sand and gravel by a rotor jet machine 1. In the stone mixture conveying pipeline 2, the conveying distance is 80m, and then at a distance of 15m from the nozzle 4, the cement slurry conveying pipeline 6 is merged into the sand and gravel mixture conveying pipeline 2 through two tees 5 Medium; under the action of high-pressure wind, the cement slurry and gravel mixture are mixed, sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com