Lock

A lock cylinder and lock shell technology, applied in the field of locks, can solve the problems of poor anti-opening performance, repeated turning and insertion of keys, inconvenient blade hole processing, etc., to achieve strong anti-theft performance, good anti-theft performance, mutual opening low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

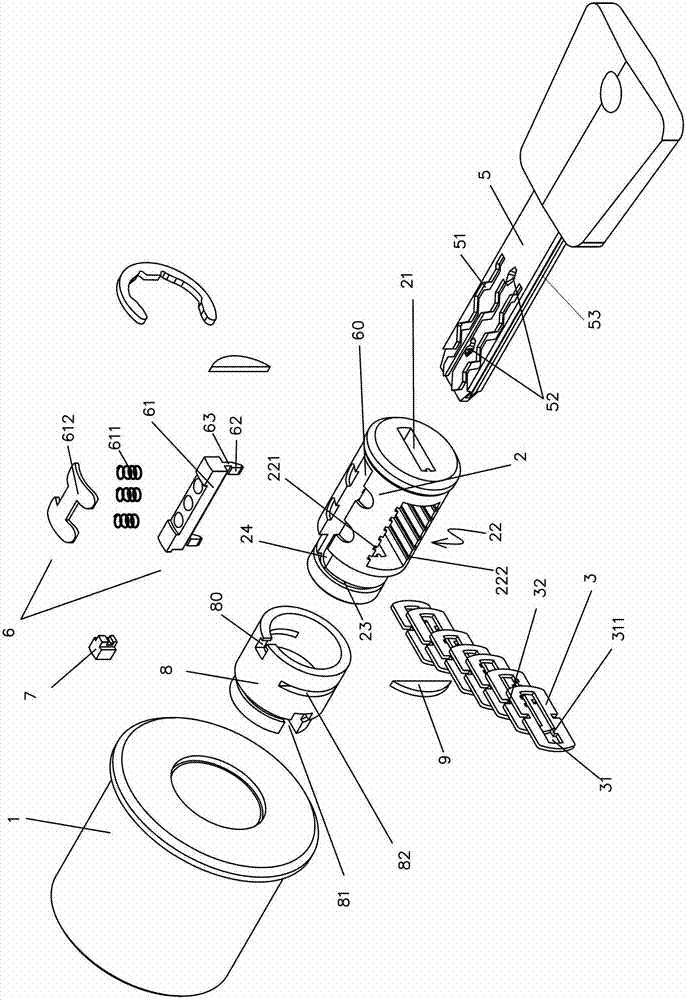

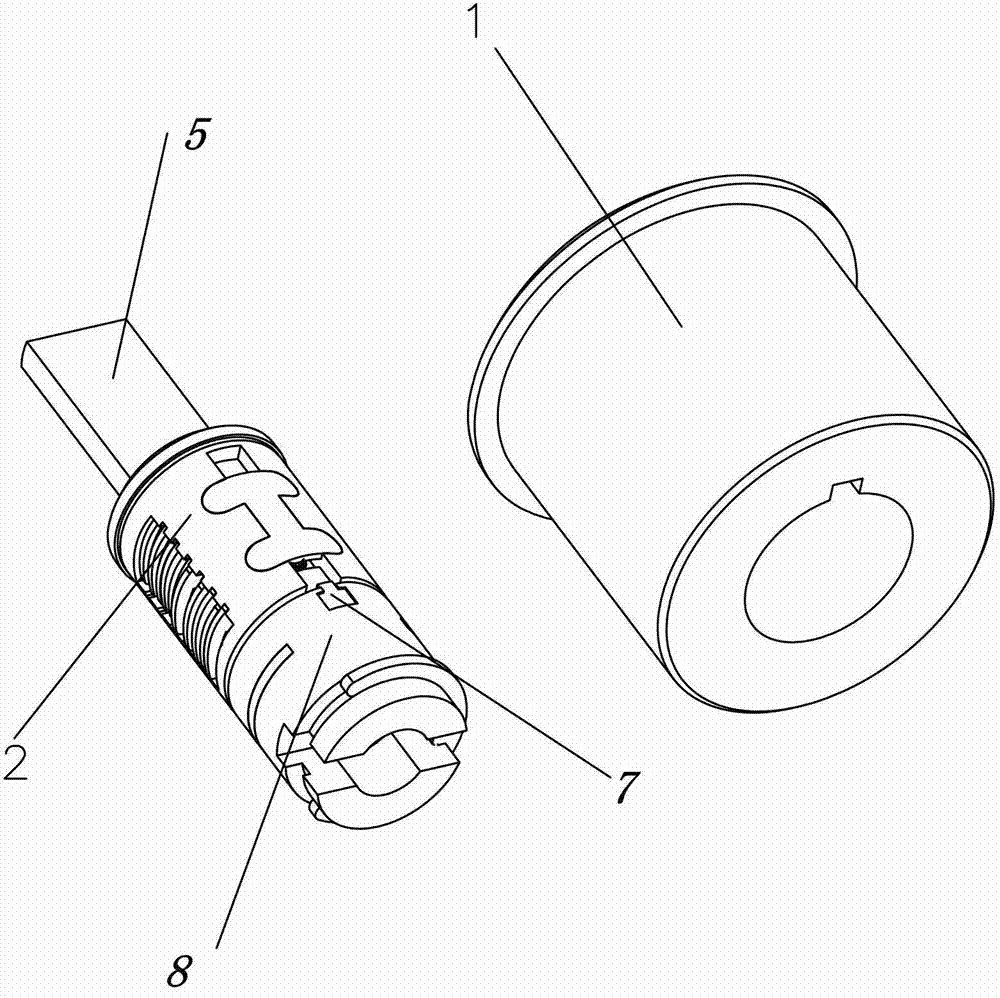

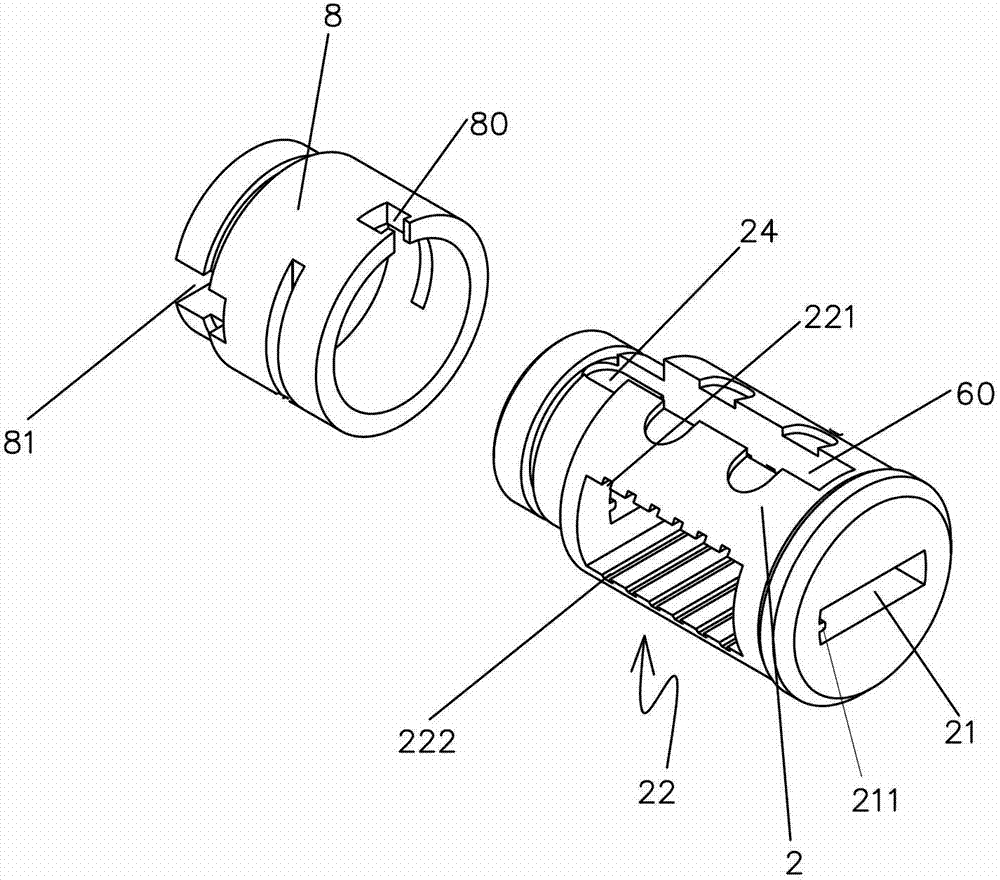

[0035] A lock, which includes a lock case 1 and a lock cylinder 2 that can rotate in the lock case driven by a key. The lock case 1 is also provided with a tail sleeve 8 that can rotate in the lock case and is sleeved on the inside of the lock cylinder 2 , the inner side of the tail cover 8 is provided with a starting key groove 81; the lock cylinder 2 is provided with a keyhole 21, and one side of the keyhole 21 is provided with a bumper lifting groove 60 communicating with it, and the bumper lifting groove 60 is provided with a There is a bumper assembly 6, and the bumper assembly 6 includes a bumper 61, a return spring 611 that drives the bumper to reset and a safety cover 612, the lower end of the bumper 61 is at least provided with a bumper bump 62, and the periphery of the keyhole 21 is provided with a bumper. There is a blade hole 22, which is provided with a plurality of blades 3 that are closely connected and can move laterally in the blade hole, and each blade 3 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com