Vane marble lockset adopting milling teeth groove key

A blade and marble technology, applied in the field of blade pin locks, can solve problems such as the limitation of the number of lock keys, the impact of anti-theft performance, and the increase of mutual opening rate, and achieve the effect of good anti-theft performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

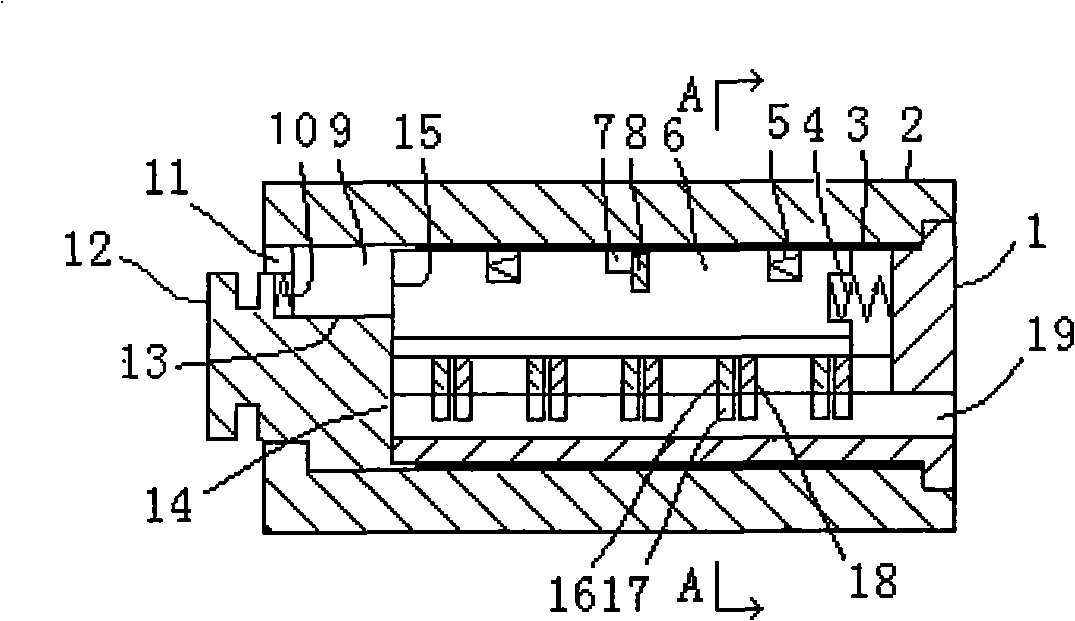

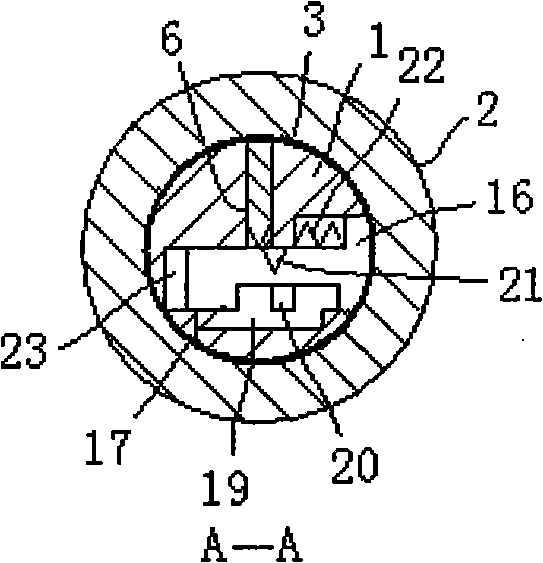

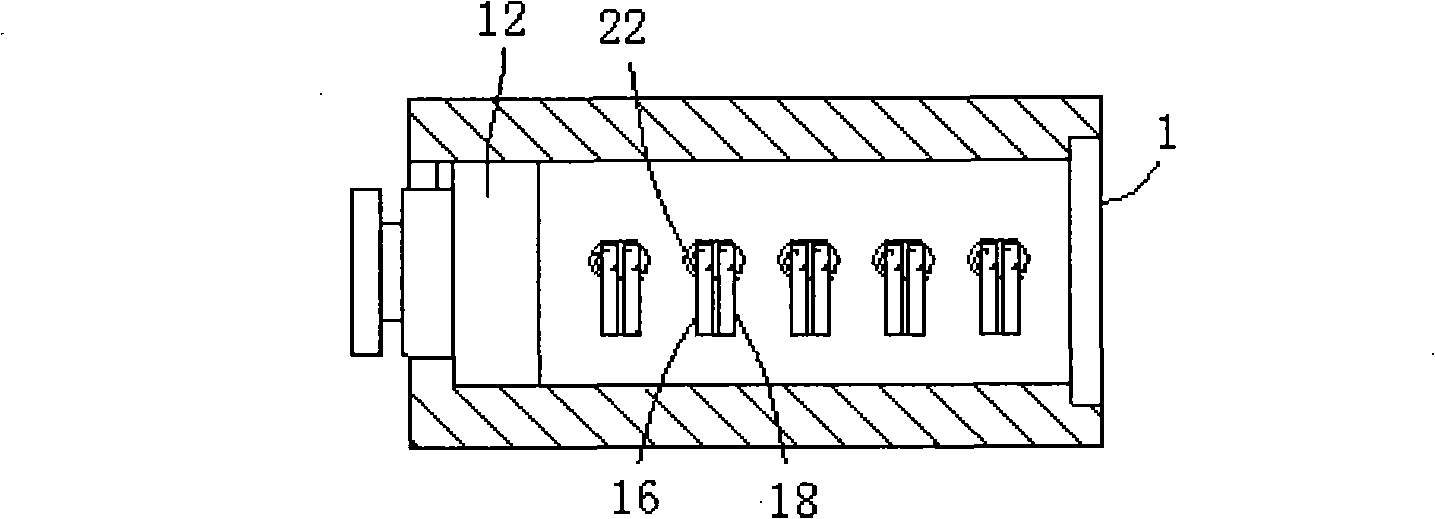

[0020] See Figure 1 to Figure 5 , the lock head of the present invention includes a lock body 2, a front lock cylinder 1 and a rear lock cylinder 12 in the lock body 2, and the front lock cylinder 1 is provided with several blade pinholes 23 along the axis, in which there are two blade pinholes. 16 and 18 are a group of blade pin groups, the end of the blade pin 16 and the middle part of the blade pin 18 in the blade pin groups on the same side are respectively provided with projections 17, 20 extending into the keyhole 19, and each blade The other side of the pin is provided with a V-shaped groove 21, and the blade pin return spring 22 is respectively arranged on the corresponding blade pins on the front lock core 1; The locking side post 6 matched with the shaped groove 21, the locking side post 6 is provided with a stepped groove 7, and the upper part of the locking side post groove is provided with a card 8 and a fixed Components, the fixed part adopts the sleeve 3 that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com