Mercerized yarn, pulp-free woven fabric and production methods of mercerized yarn and pulp-free woven fabric

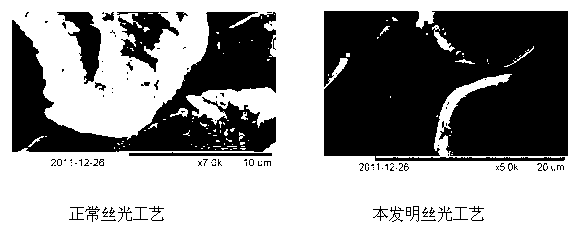

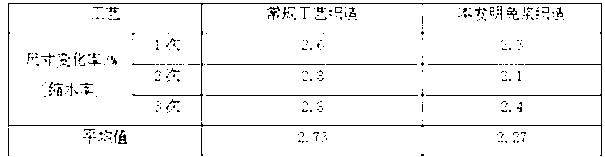

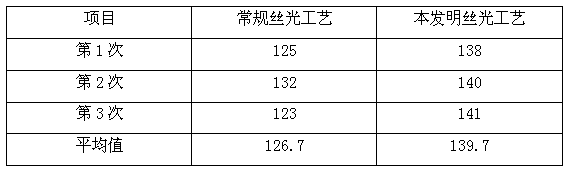

A production method and yarn technology, which is applied in the direction of mercerization, yarn, fabric, etc. of yarn/thread/filament, can solve the problems of not involving dyed yarn, limited application range, etc., and achieve perfect dimensional stability, smoothness and hairiness Effects of low residue and shortened post-finishing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The warp yarn is 100S / 2 mercerized cotton white yarn, and the weft yarn is 100S / 2 fine cotton. The processing method of the size-free woven fabric is as follows:

[0042] 1. Yarn singeing: Singeing the 100S / 2 yarn on the yarn singeing machine, the stability of the burner is 1000°C, and the speed is 900 m / min. After singeing, the surface of the yarn is smooth, free of yellowish white and strong damage phenomenon.

[0043] 2. Shaking yarn: shake the tubular singeed yarn on the yarn shaking machine into 550g skeins per skein.

[0044] 3. Mercerizing: Put the skeined yarn on the yarn mercerizing machine for mercerizing treatment, the concentration of mercerizing lye is 25 degrees Baume, the stretching length is 3.5%, the reaction time is 4 minutes, the reaction temperature is 17°C, and hot water washing The temperature is 30°C.

[0045] 4. Dyeing: The yarn after mercerizing is washed with hot water, pickled, boiled, bleached and dyed successively, so that the yarn is dyed w...

Embodiment 2

[0063] The processing method of the size-free woven fabric whose warp is 80S / 2 mercerized cotton / linen natural color yarn and weft is 80S / 2 mercerized cotton is as follows:

[0064] 1. Yarn singeing: The 80S / 2 cotton / linen yarn is singeed on the yarn singeing machine. After singeing, the surface of the yarn is smooth without yellowish white and strong damage.

[0065] 2. Shaking yarn: shake the tubular singeed yarn on the yarn shaking machine into 550g skeins per skein.

[0066] 3. Mercerizing: The skeined yarn is subjected to mercerizing treatment on a yarn mercerizing machine, the concentration of mercerizing lye is 30 degrees Baume, the stretching length is 2.8%, the reaction time is 3.5 minutes, the reaction temperature is 19°C, and hot water washing The temperature is 60°C.

[0067] 4. Water washing: the yarn after mercerizing is washed with hot water, acid washed, and washed until neutral.

[0068] 5. Drying: The dyed yarn is dried in a drying room to make the moisture...

Embodiment 3

[0080] The processing method of the size-free woven fabric whose warp yarn is 120S / 2 mercerized cotton blue yarn and weft yarn is 100S / 2 white cotton / tencel yarn is as follows:

[0081] 1. Yarn singeing: The cotton 120S / 2 yarn is singeed on the yarn singeing machine. After singeing, the surface of the yarn is smooth and clean, without yellowish white and strong damage.

[0082] 2. Shaking yarn: Shake the tubular singeed yarn on the yarn shaking machine into skeins of 300g per skein.

[0083] 3. Mercerizing: The skeined yarn is subjected to mercerizing treatment on a yarn mercerizing machine, the concentration of mercerizing lye is 32 degrees Baume, the stretching length is 2.5%, the reaction time is 5 minutes, the reaction temperature is 22 ° C, hot water washing The temperature was 85°C.

[0084] 4. Dyeing: The yarn after mercerizing is washed in hot water, pickled, boiled and dyed into blue in sequence.

[0085] 5. Drying: The dyed yarn is dried in a drying room to make th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com