Preparation method of zinc oxide/ cuprous oxide heterojunction

A cuprous oxide, heterojunction technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, electrolytic inorganic material coating, etc., can solve problems such as complex process and achieve the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

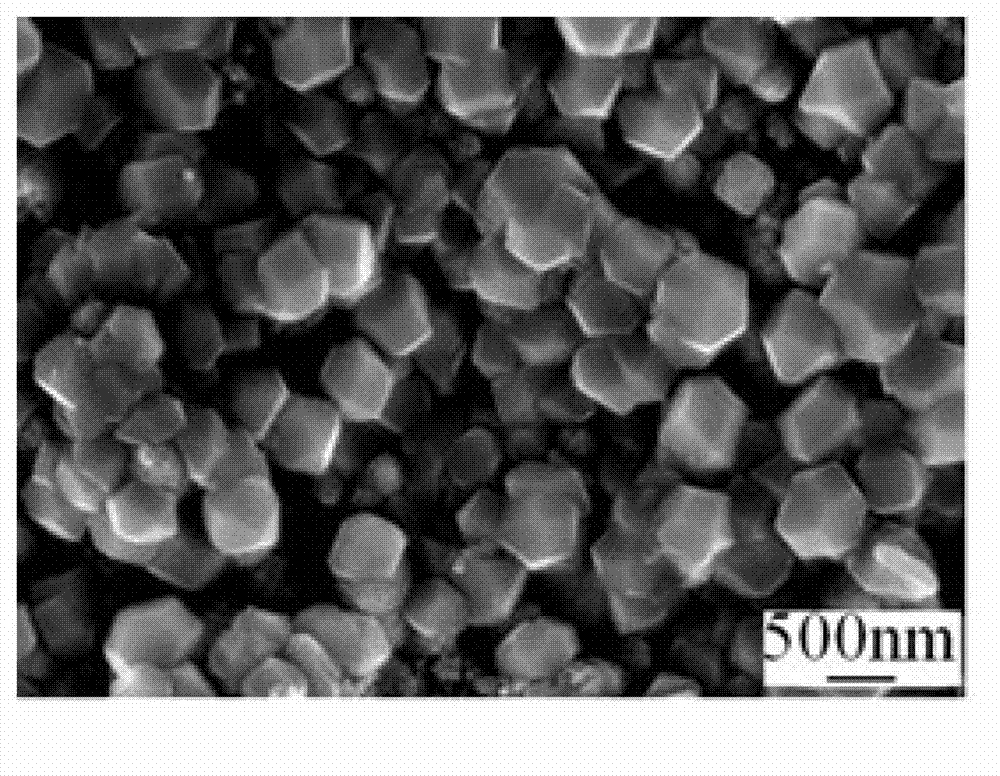

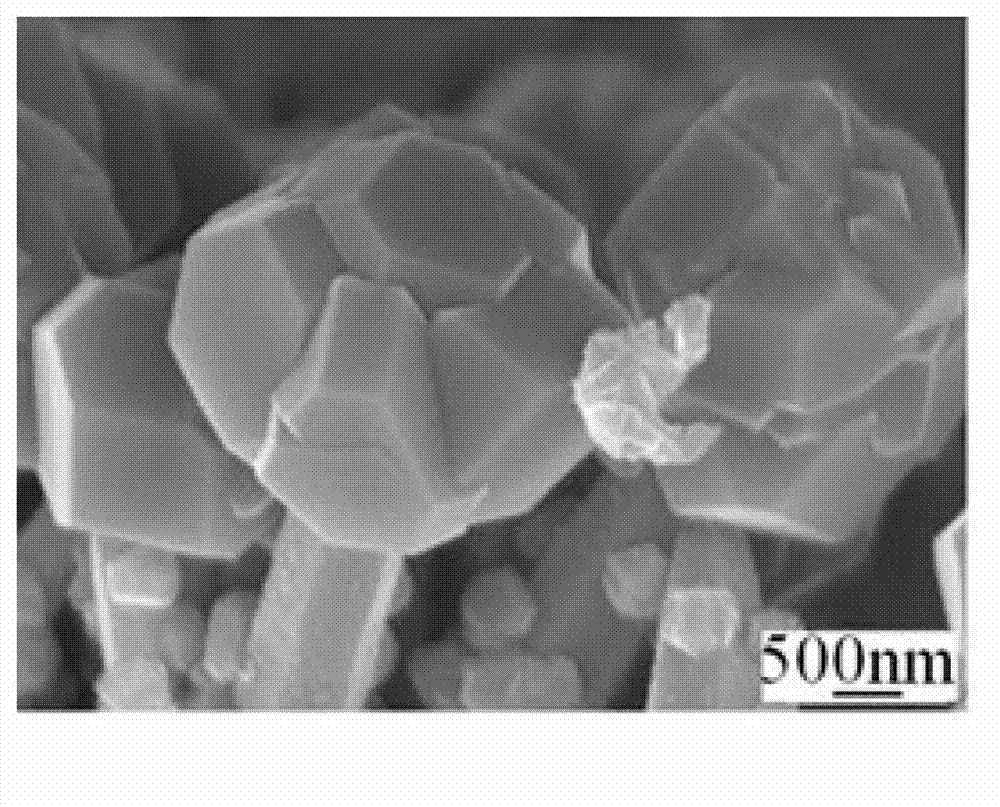

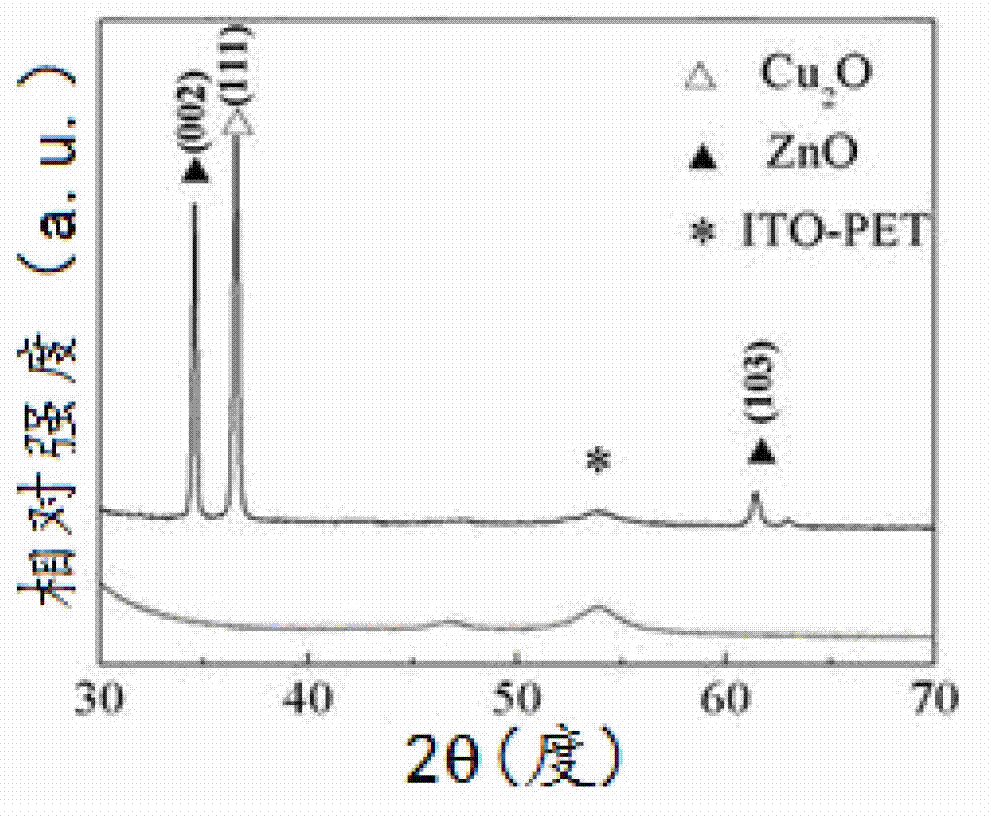

[0022] Example 1, the flexible ITO substrate was ultrasonically cleaned for 20 minutes with distilled water, absolute ethanol, acetone, and absolute ethanol in sequence, then rinsed several times with deionized water, and dried for later use. Weigh 0.0744g of Zn(NO 3 ) 2 ·6H 2 O and 0.0351g of hexamethylenetetramine were dissolved in an appropriate amount of deionized water to form a solution with a concentration of 0.002M, and then stirred on a magnetic stirrer for 20 minutes to obtain a uniform electrolyte. Electrochemical deposition was carried out on E-corder401 electrochemical workstation, using a standard three-electrode system, the flexible ITO substrate was used as the working electrode, the platinum sheet was used as the counter electrode, and the reference electrode was Ag / AgCl. The deposition temperature was controlled at 40°C and the transverse potential was -1.3V. After 0.5h, a pencil-like ZnO nanorod array was obtained, rinsed with deionized water, and then dri...

Embodiment 2

[0024] Example 2, the flexible ITO substrate was ultrasonically cleaned for 25 minutes with distilled water, absolute ethanol, acetone, and absolute ethanol in sequence, then rinsed several times with deionized water, and dried for later use. Weigh 0.1488g of Zn(NO 3 ) 2 ·6H 2 O and 0.0702g of hexamethylenetetramine were dissolved in an appropriate amount of deionized water to form a solution with a concentration of 0.005M, and then stirred on a magnetic stirrer for 25 minutes to obtain a uniform electrolyte. Electrochemical deposition was carried out on E-corder401 electrochemical workstation, using a standard three-electrode system, the flexible ITO substrate was used as the working electrode, the platinum sheet was used as the counter electrode, and the reference electrode was Ag / AgCl. The deposition temperature was controlled at 50°C and the transverse potential was -1.4V. After 1h, pencil-like ZnO nanorod arrays were obtained, rinsed with deionized water, and then dried...

Embodiment 3

[0026] Example 3, the flexible ITO substrate was ultrasonically cleaned for 35 minutes with distilled water, absolute ethanol, acetone, and absolute ethanol in sequence, then rinsed several times with deionized water, and dried for later use. Weigh 0.2232g of Zn(NO 3 ) 2 ·6H 2 O and 0.1053g of hexamethylenetetramine were dissolved in an appropriate amount of deionized water to form a solution with a concentration of 0.008M, and then stirred on a magnetic stirrer for 35 minutes to obtain a uniform electrolyte. Electrochemical deposition was carried out on E-corder401 electrochemical workstation, using a standard three-electrode system, the flexible ITO substrate was used as the working electrode, the platinum sheet was used as the counter electrode, and the reference electrode was Ag / AgCl. The deposition temperature was controlled at 60°C and the transverse potential was -1.5V. After 1.5h, a pencil-like ZnO nanorod array was obtained, rinsed with deionized water, and then dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com