Method for producing acetone butanol from fermented cassava

A kind of technology of acetone butanol and cassava, applied in the field of fermentation production of acetone butanol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

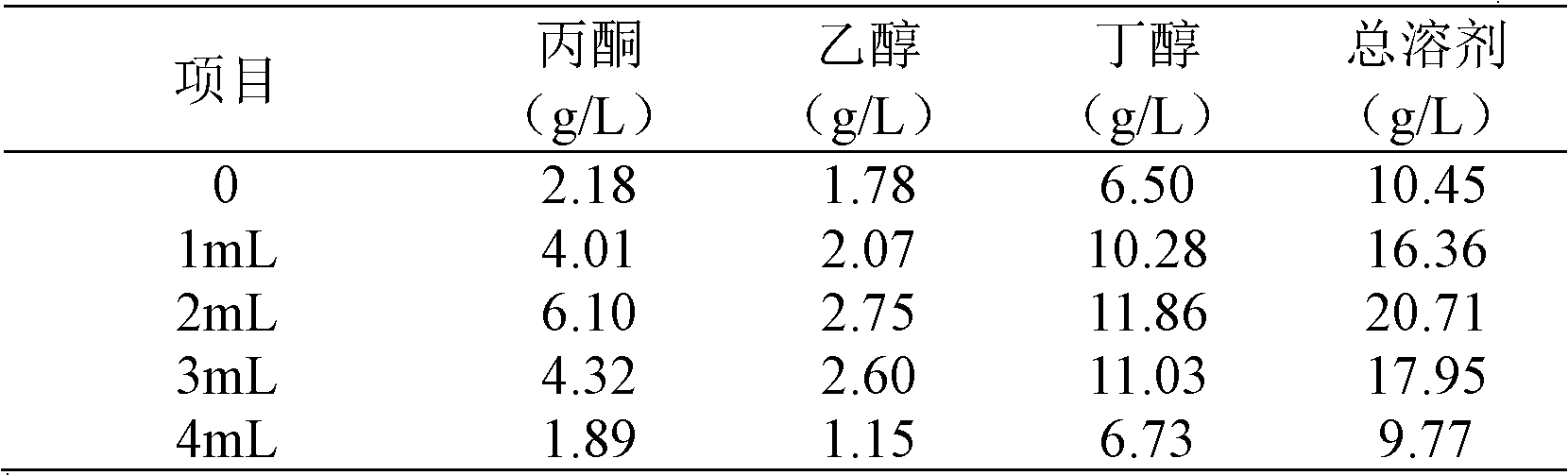

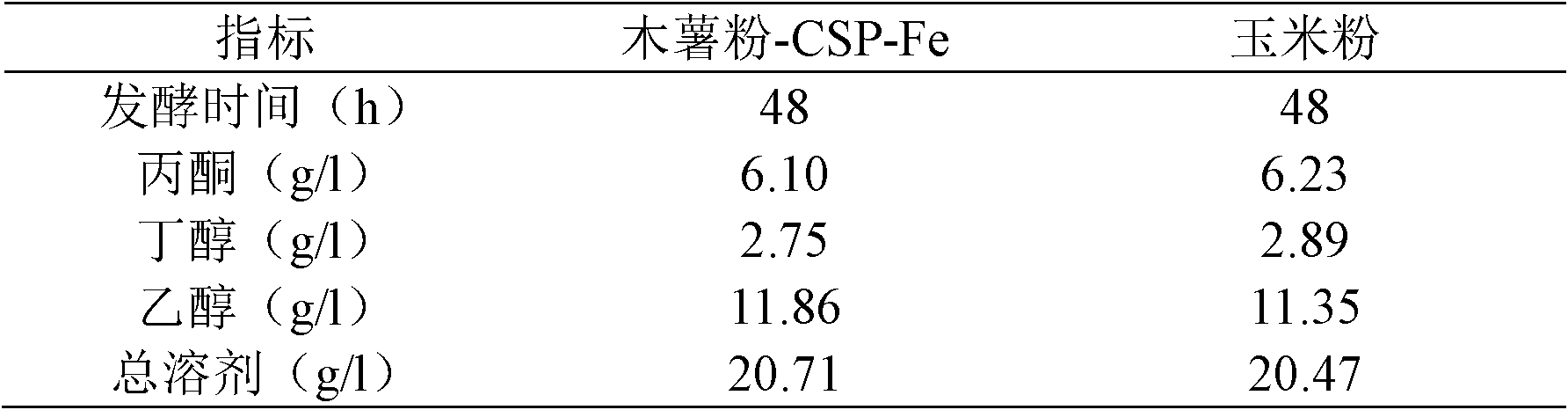

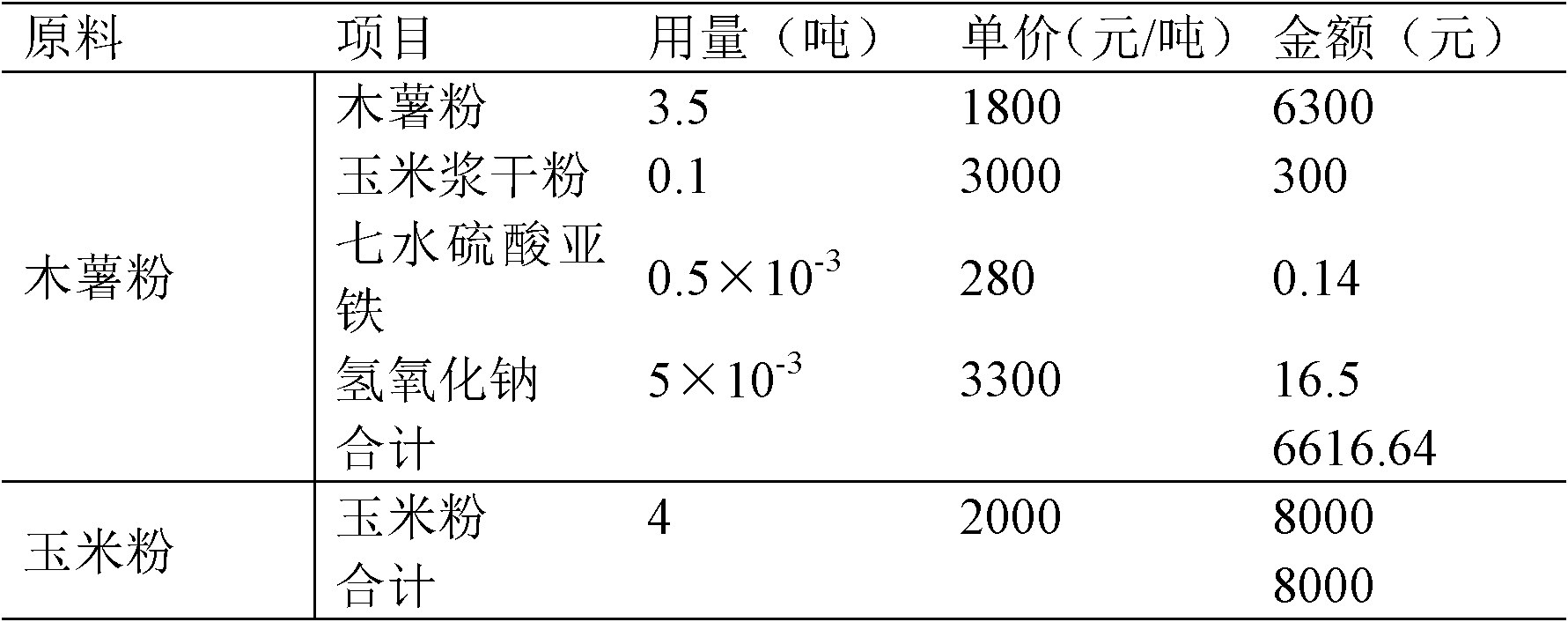

[0016] Embodiment 1: Clostridium acetobutylicum ATCC 824 utilizes cassava flour optimization medium fermentation to produce ABE

[0017] Prepare 200ml of cassava flour medium, medium composition: 7% cassava flour, boil and gelatinize the prepared cassava flour fermentation medium for 10min, transfer it to a 250ml shake flask, and autoclave at 121°C for 1.5h. To prepare the CSP-Fe solution, first prepare 100 mL of 20% corn steep liquor dry powder solution, add 0.1 g of ferrous sulfate heptahydrate, adjust the pH to 7.0 with sodium hydroxide, and autoclave at 121° C. for 20 minutes. When the temperature of the culture medium was lowered to below 40°C, different amounts of sterilized CSP-Fe solutions were added to the cassava flour, and then the activated Clostriidium acetobutylicum (Clostriidium acetobutylicum) ATCC 824 bacterial solution was inserted for 24 hours, and the inoculum size was 10 %, 37 ℃ fermentation culture.

[0018] After the fermentation, the fermentation broth...

Embodiment 2

[0030] Example 2: Fermentation of C.butylicum 23592 using cassava flour optimized medium to produce ABE

[0031] The cassava flour medium and CSP-Fe solution were prepared as described in Example 1. After the temperature of the medium was lowered to below 40°C, 2 mL of the sterilized CSP-Fe solution was added to the cassava flour, and then the activated C. Butylicum 23592 bacterial liquid, inoculum size 10%, fermented at 37°C.

[0032] After the fermentation, the fermentation broth was taken, the sample was centrifuged at 10000rpm for 10min, and the supernatant was collected. The ABE solvent components in the supernatant were analyzed by gas chromatography (GC).

[0033] The results showed that when no CSP-Fe solution was added, the rate and yield of ABE solvent produced by cassava flour fermented by C.butylicum 23592 bacterial liquid were low, and the total solvent concentration at the end of fermentation was 9.26g / L; After 2mL of CSP-Fe mixed solution, the total solvent co...

Embodiment 3

[0034] Example 3: C.acetobutylicum 170 uses cassava flour to optimize medium fermentation to produce ABE

[0035] The cassava flour medium and CSP-Fe solution were prepared as described in Example 1. After the temperature of the medium was lowered to below 40°C, 2 mL of the sterilized CSP-Fe solution was added to the cassava flour, and then the activated C. Acetobutylicum 170 bacteria liquid, 10% inoculum, fermented at 37°C.

[0036] After the fermentation, the fermentation broth was taken, the sample was centrifuged at 10000rpm for 10min, and the supernatant was collected. The ABE solvent components in the supernatant were analyzed by gas chromatography (GC). The results showed that when no CSP-Fe solution was added, the rate and yield of ABE solvent produced by cassava flour fermented by C.acetobutylicum 170 bacteria liquid were low, and the total solvent concentration at the end of fermentation was 10.18g / L; After 2mL of CSP-Fe mixed solution, the total solvent concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com