Demulsification method for extracting soybean oil by aqueous enzymatic method

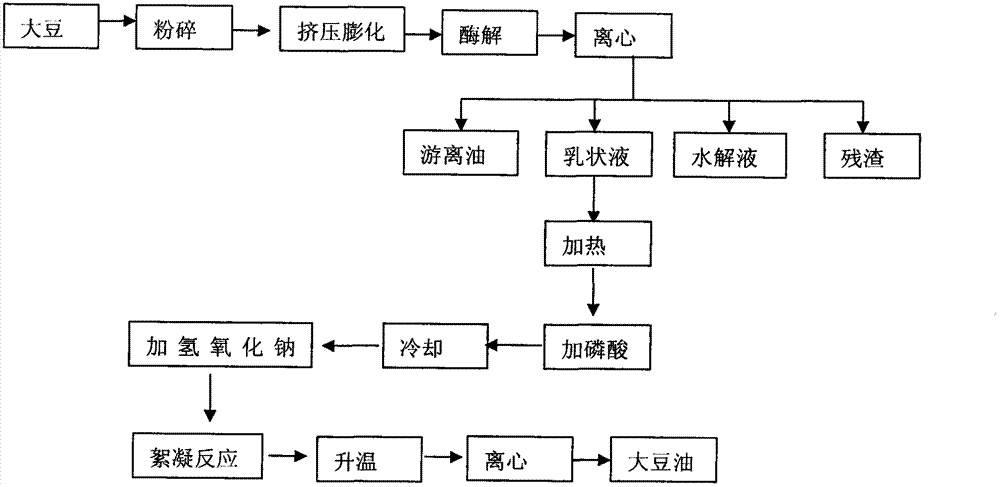

A soybean oil and water enzymatic technology, which is applied in the production of oil/fat and fat production, can solve the problems of low demulsification rate and long demulsification time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

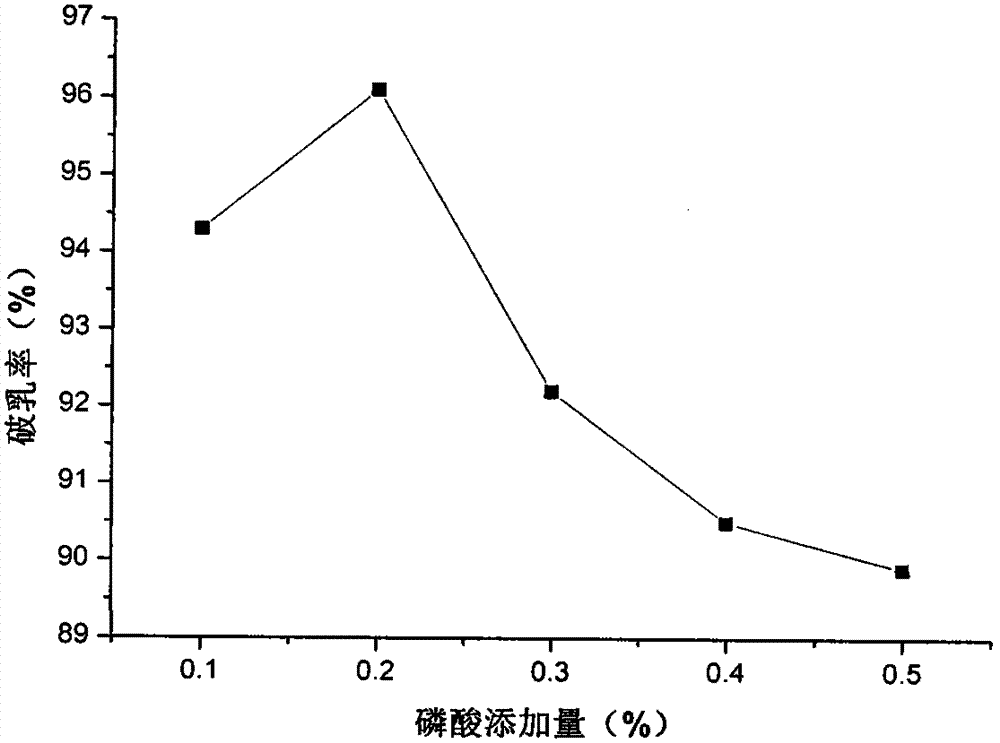

[0021] Example Demulsification Process Optimal Parameter Screening Test

[0022] 1 Materials and methods

[0023] 1.1 Test raw materials

[0024] Soybean Kennong 42 cultivated by Heilongjiang Academy of Agricultural Sciences, the protein content is 41.6%, the oil content is 21.3%, the moisture content is 10.6%, and the ash content is 4.3%.

[0025] Alcalase alkaline endoprotease novo (1.2×10 5 U / mL)

[0026] 2.1.2 Test instruments and equipment

[0027] Instrument Manufacturer

[0028] CX-500 Ultrasonic Cleaner Beijing Second Medical Equipment Factory

[0029] Electronic Analytical Balance METTLER TOLEDO Instruments (Shanghai) Co., Ltd.

[0030] Hammer Mill China Tianjin Test Instrument Co., Ltd.

[0031] LDZ5-2 Desktop Low Speed Centrifuge Shanghai Anting Scientific Instrument Factory

[0032] Electric constant temperature water bath Yuyao Dongfang Electrical Instrument Factory

[0033] TGL-16G High Speed Desktop Centrifuge Shanghai Anting Scientific Instrument F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com