Method for preparing erythromycin thiocyanate

A technology of erythromycin thiocyanate and erythromycin, which is applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve problems such as affecting product quality stability and product quality fluctuations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

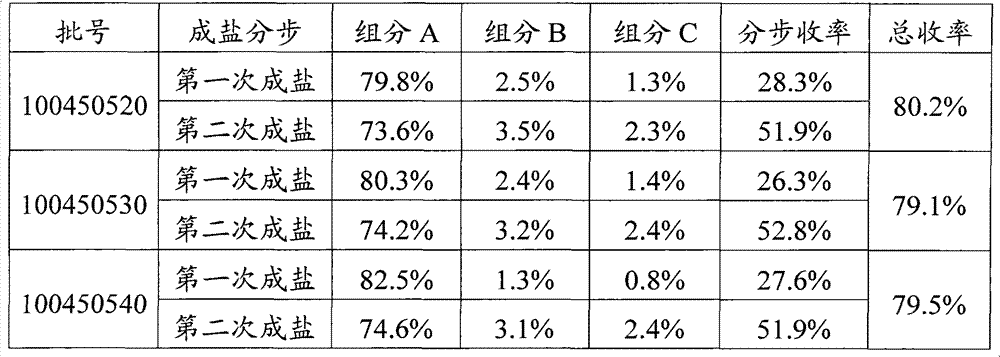

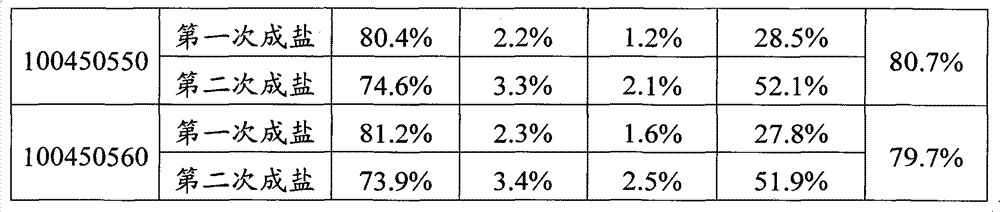

[0027] Take 100350530 batches of erythromycin extract 2T after washing (potency 35862u / ml, components A96.3%, B2.5%, C1.2%), and heat to 38°C. According to the calculation of 1.5L / billion, 107.6L of 15% sodium thiocyanate solution should be added. The first salt crystallization: first add 36L of 15% sodium thiocyanate solution, start stirring, slowly add 15% acetic acid solution, adjust the pH to 8.0 to form salt crystallization. After 20 minutes, the crystallization solution was separated by vacuum filtration. After being drained, rinse with a small amount of new ethyl acetate and drain. Then soak and wash with purified water at 55°C, then drain and vacuum dry to obtain 20.10Kg of finished product, with a billion yield of 27.3%, components A80.2%, B2.5%, and C1.4%; the second time Salt formation and crystallization: maintain the separated crystallization mother liquor at 38°C, add 71.6L of 15% sodium thiocyanate solution, start stirring, slowly add 15% acetic acid solution,...

Embodiment 2

[0029] Take 100350560 batches of erythromycin extract 2T after washing (potency 36570u / ml, components A94.2%, B3.6%, C2.2%), and heat to 35°C. According to the calculation of 1.2L / billion, 87.76L of 20% sodium thiocyanate solution should be added. The first salt crystallization: first add 21.9L of 15% sodium thiocyanate solution, start stirring, slowly add 15% acetic acid solution, and adjust the pH to 8.2 to form salt crystallization. After 20 minutes, the crystallization solution was separated by vacuum filtration. After being drained, rinse with a small amount of new butyl acetate and drain. Then soak and wash with purified water at 55°C, then drain and vacuum-dry to obtain 19.82Kg of finished product, with a yield of 25.7% per billion, and components A78.1%, B2.7%, and C1.8%; the second time Salt formation and crystallization: maintain the separated crystallization mother liquor at 36°C, add 65.86L of 20% sodium thiocyanate solution, start stirring, slowly add 15% acetic...

Embodiment 3

[0031] Take 100350580 batches of erythromycin extract 2T after washing (potency 37605u / ml, components A97.1%, B1.9%, C1.0%), and heat to 40°C. According to the calculation of 1.3L / billion, 97.8L of 18% sodium thiocyanate solution should be added. The first salt crystallization: first add 31.2L of 15% sodium thiocyanate solution, start stirring, slowly add 15% acetic acid solution, and adjust the pH to 8.0 to form salt crystallization. After 20 minutes, the crystallization solution was separated by vacuum filtration. After being drained, rinse with a small amount of new butyl acetate and drain. Then soak and wash with purified water at 55°C, then drain and vacuum-dry to obtain 26.33Kg of finished product, the yield per billion is 28.5%, and components A80.4%, B2.1%, and C1.2%; the second time Salt formation and crystallization: maintain the separated crystallization mother liquor at 40°C, add 66.6L of 18% sodium thiocyanate solution, start stirring, slowly add 15% acetic acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com