Meat grinding mechanism body and method for manufacturing same

A body and minced meat technology, applied in grain processing, etc., can solve the problems of shrinkage cavities, pores, unstable material hardness, and low accuracy of the body, so as to eliminate shrinkage cavities, improve production efficiency, and stabilize the size of the body Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the drawings and embodiments.

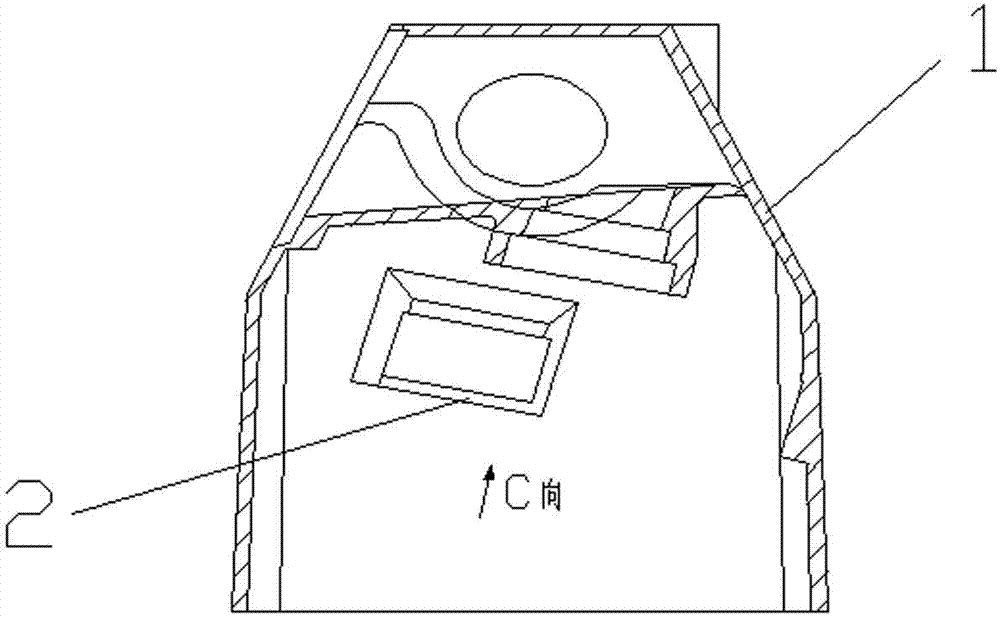

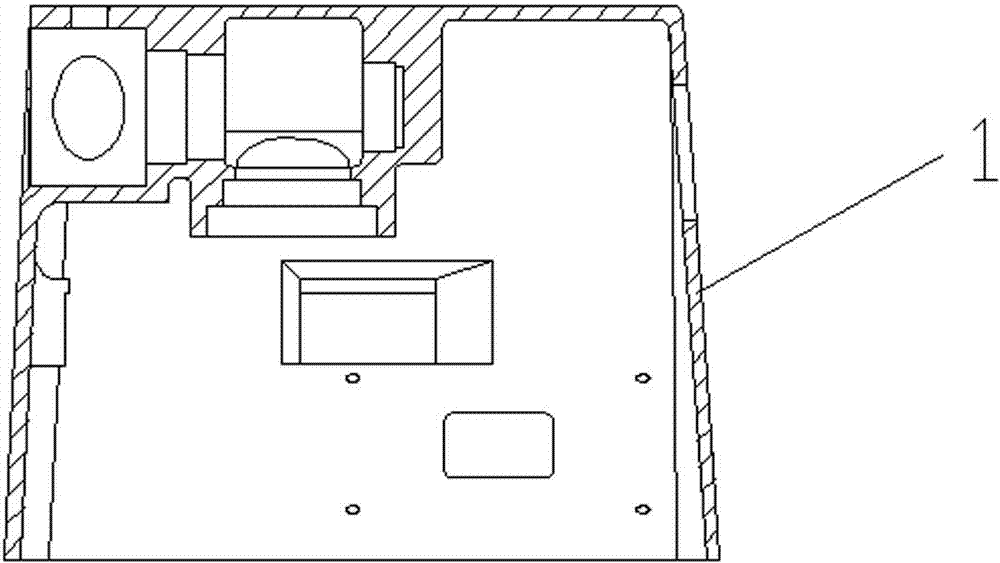

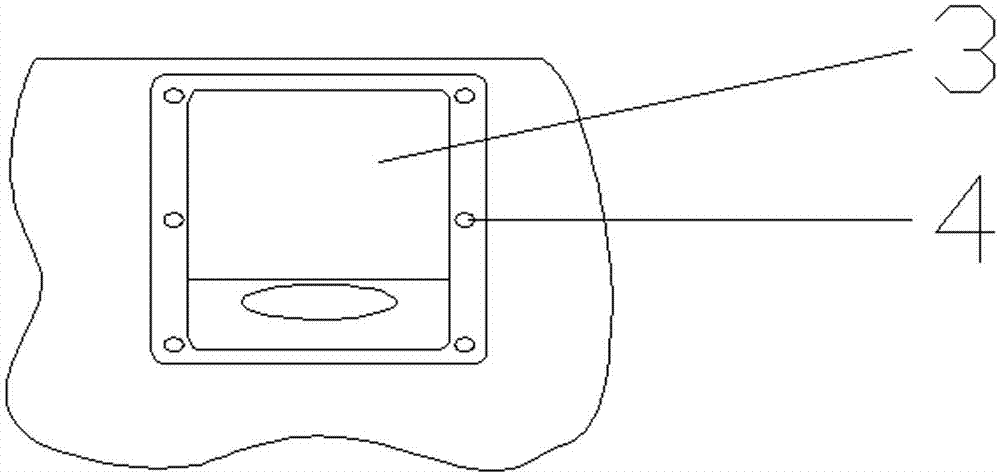

[0016] See Figure 1 to Figure 3 , A body of a meat grinder, comprising a body 1. The oil cavity of the body 1 is provided with a rectangular hole 2 that is convenient for smoothly extracting the mandrel in the oil cavity; during assembly, the rectangular hole 2 Cover the upper part with a die-cast aluminum plate 3 and a gasket, and fasten on the body 1 with screws 4.

[0017] The method for making the body of the above-mentioned meat grinder is as follows:

[0018] The first step: first make a metal mold according to the structural characteristics of the machine body, and then according to the needs of the die-casting process, open a rectangular hole on the side of the oil cavity of the machine body to facilitate the smooth extraction of the core mold in the oil cavity;

[0019] Step 2: Heat the solid aluminum to 660.4°C before casting to melt it into liquid aluminum, pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com