Novel gravity separator

A new type of gravity separation technology, which is applied in the direction of solid separation, separation of solids from solids with air flow, and filtration and screening, can solve the problems of unknown separation effect and achieve good separation effect and separation effect good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

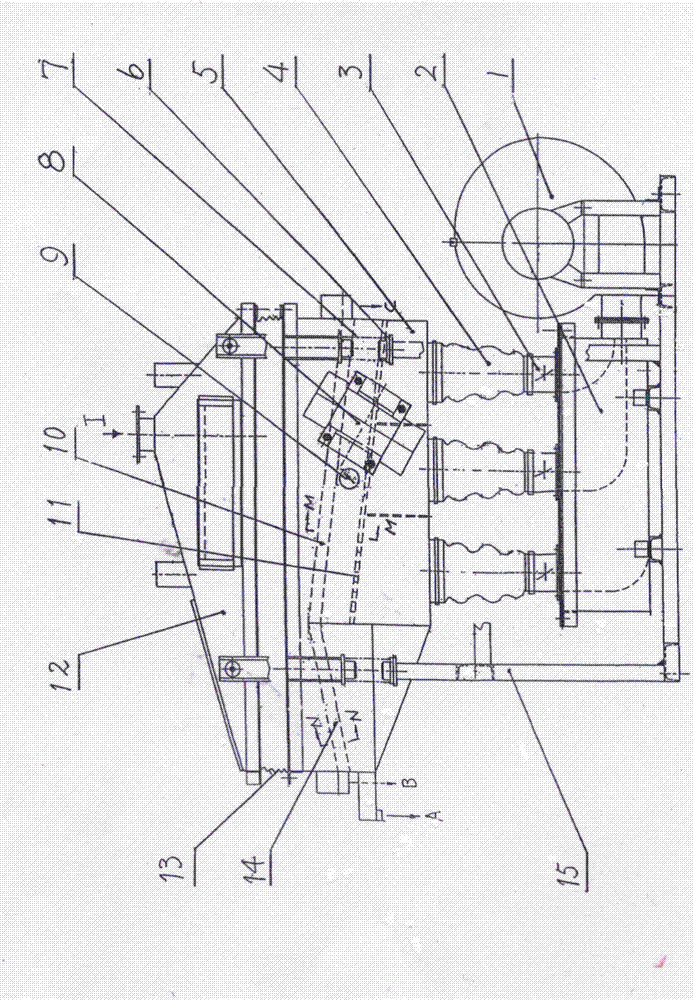

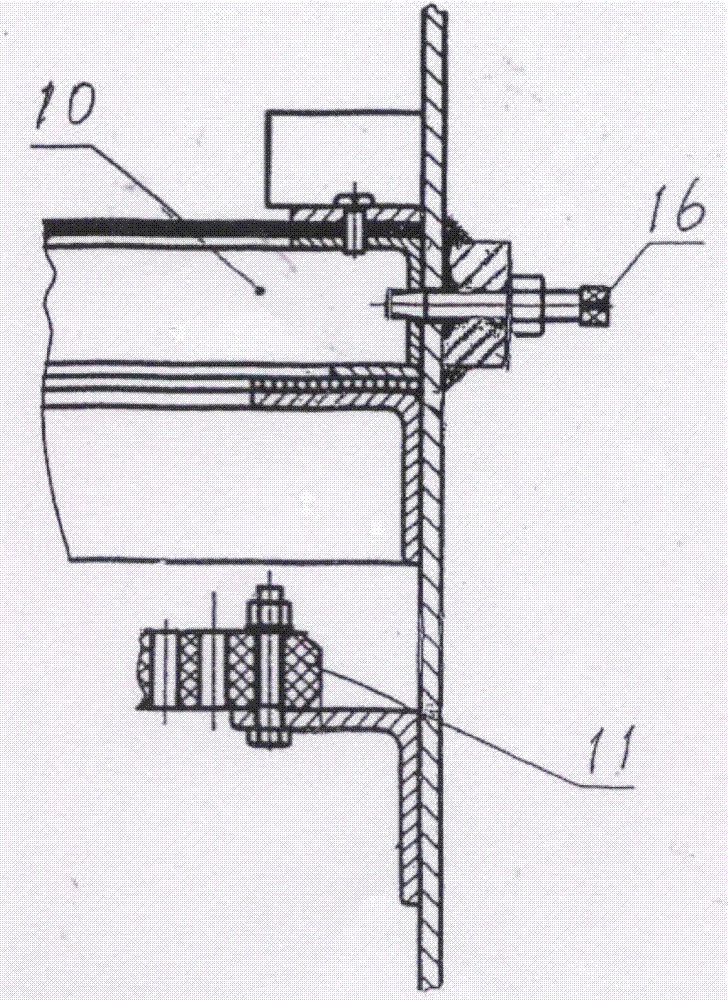

[0032] As shown in the figure, the new gravity separator consists of an air filter 19, blower 1, bellows 2, air volume valve 3, hose 4, vibration box 5, vibration motor 8, gravity separator 10, and even air plate 11. Box cover 12, soft seal 13, vibrating screen 14, spring 7, frame 15 and other components.

[0033] The air filter 19 is used to remove dust in the air to prevent the sieve plate 21 of the gravity sorting sieve 10 from being blocked. The outlet of the filter 19 is connected with the inlet of the blower 1 .

[0034] The blower fan 1 adopts a high-pressure centrifugal fan, and its outlet links to each other with the inlet of the bellows 2.

[0035] In order to obtain a better separation effect, the inner cavity of the bellows 2 is divided into three chambers, which communicate with the three air outlets of the upper cover respectively, and the three air outlets are respectively connected with the corresponding air volume adjustment doors. At this time, the air volu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com