Hand stubble-cleaning return-to-field operation machine

An operation machine and stubble removal technology, which is applied in the field of agricultural farmland stubble removal operation tools, can solve the problems of stubble removal agricultural machinery safety hazards, reduced operating energy consumption, and reduced operating labor force, and achieves overcoming machine side slippage on slopes, reduced operating energy consumption, and The effect of reducing the amount of work labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

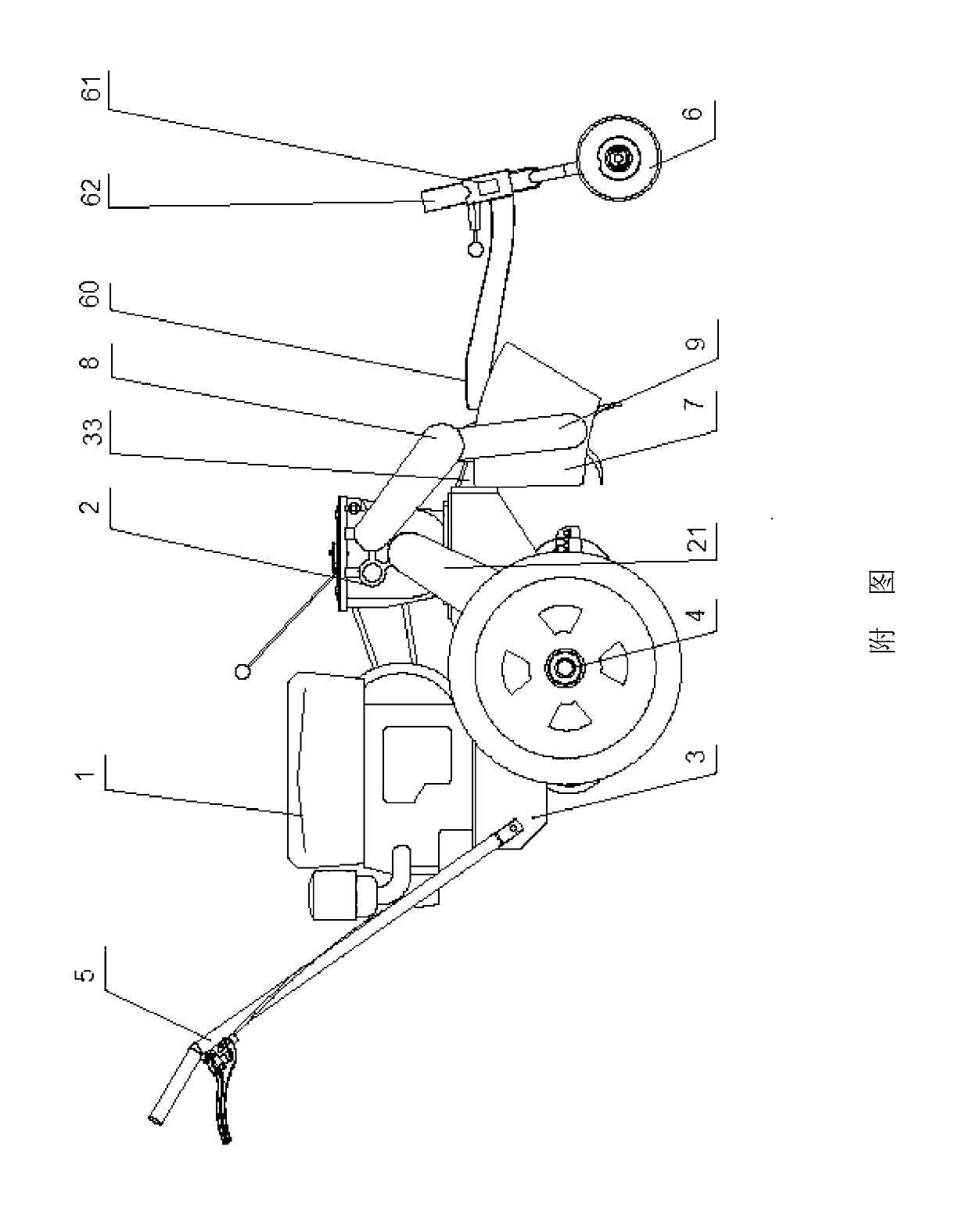

[0006] The hand-held stubble removal and returning operation machine disclosed in the patent application of the present invention is composed of a power walking main machine and a stubble removal assembly. The power walking host is composed of a frame 3, an engine 1 installed on the frame 3, a gearbox 2 and a walking part, the handle 5 is mounted on the rear end of the frame 3, the engine 1 is installed at the rear above the frame 3, and the gearbox 2 Compared with the engine 1, which is installed on the front part above the frame 3, the first variable speed output shaft of the gearbox 2 is driven by a belt or chain transmission mechanism 21 to rotate the walking wheel shaft 4 installed below the frame 3, and the two ends of the walking wheel shaft 4 are equipped with road wheels. , Horizontal ridge guide wheel 6 and support 60 thereof are installed on frame 3 front ends, and horizontal ridge guide wheel 6 and walking wheel glue front and rear support drive complete machine ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com