Method for testing internal volume of container by gas tightness detector by aid of gas-release process

A technology of air tightness detection and internal volume, which is applied in the direction of volume measurement instrument/method, liquid tightness measurement using liquid/vacuum degree, container/cavity capacity measurement, etc., which can solve the problem of large volume error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

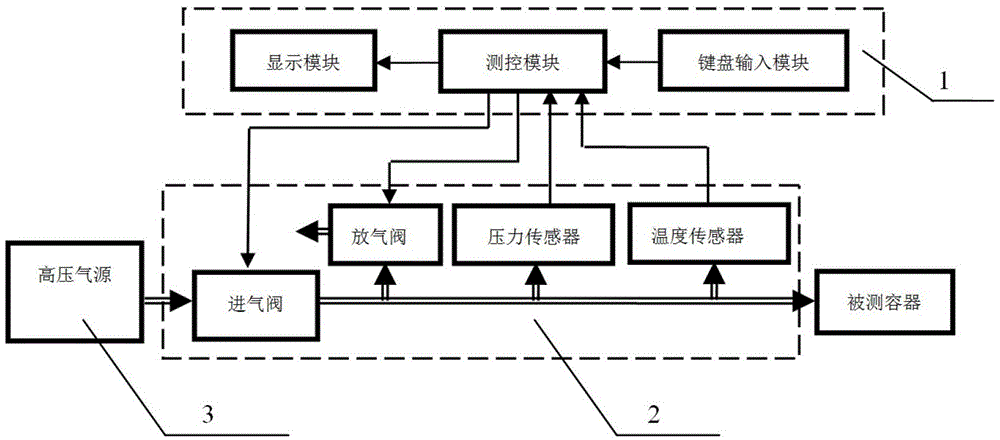

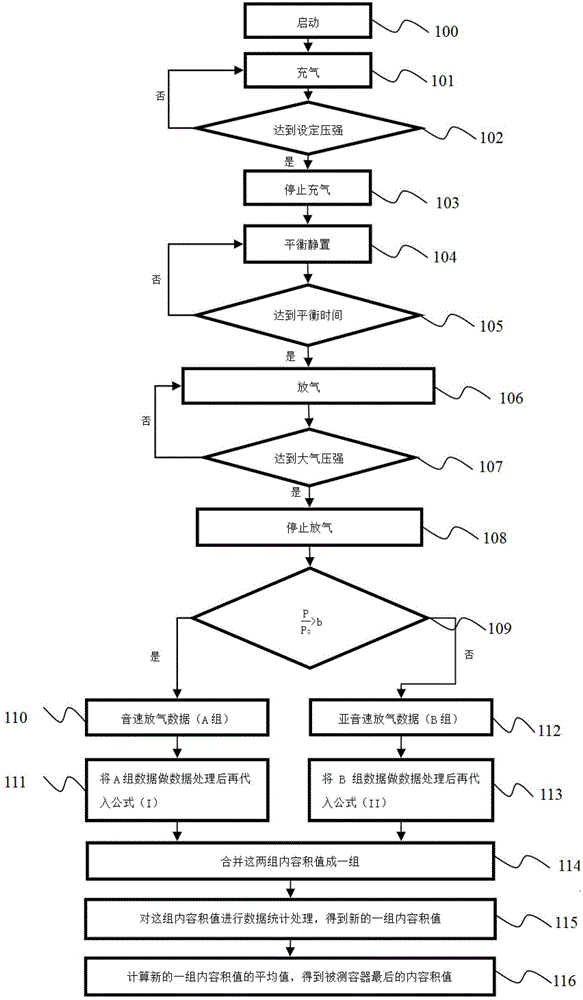

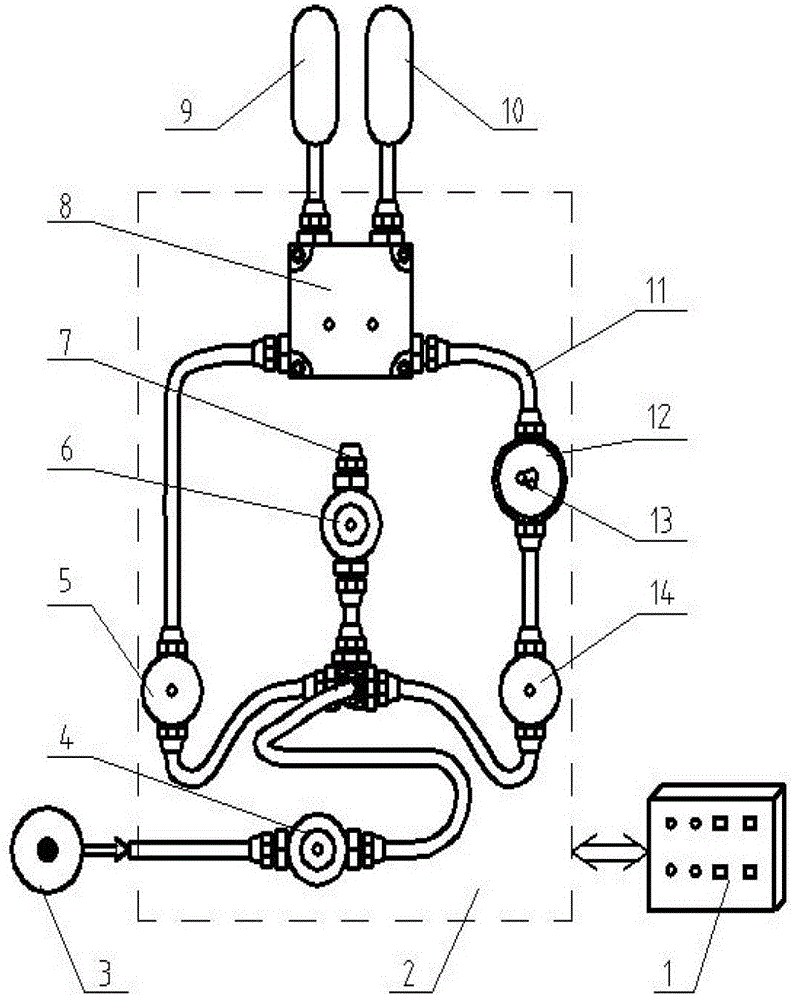

[0112] image 3 It is a structural frame diagram of the differential pressure type air tightness detector used in the embodiment of the present invention; Figure 4 Process the sampled pressure-time data value for the embodiment of the present invention; Figure 5 It is group A data, group B data and related data of the embodiment of the present invention; Figure 6 It is the pressure-time data value coordinate diagram collected during the deflation process of the measured container in the embodiment of the present invention.

[0113] exist image 3 Among them, the differential pressure type air tightness detector used in the embodiment includes: microcontroller 1, air tightness detector air circuit 2, high pressure air source 3, intake valve 4, test valve 5, air release valve 6, air release valve Air interface 7, differential pressure sensor 8, standard container 9, measured container 10, gas pipe 11, pressure sensor 12, temperature sensor 13;

[0114] The measurement and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com