Multi-reflection inhibiting method in in-situ measurement of high reflection metal structural component

A technology for metal structural parts and reflection suppression, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of improving the difficulty of strong reflective metal structural parts and difficult control of ambient light interference, so as to improve feasibility and practicability. Ensure correctness and practicality, and solve measurement problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to better understand the present invention, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

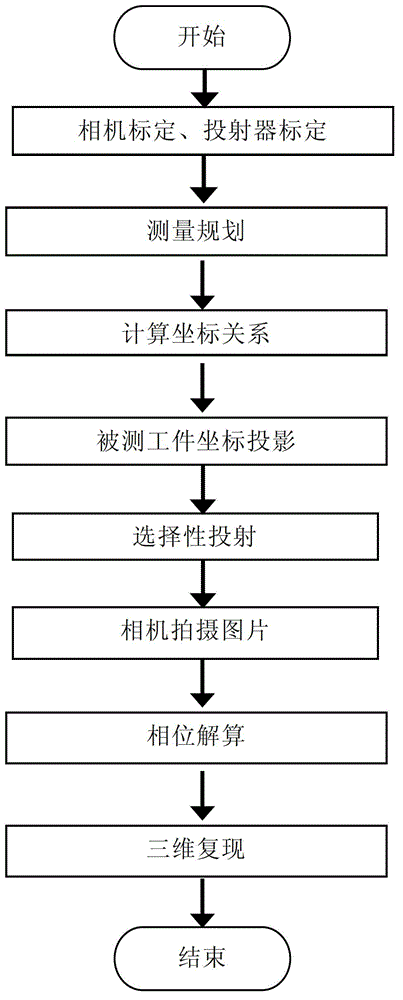

[0033] Refer to attached figure 1 , a method for suppressing multiple reflections in in-situ measurement of a highly reflective metal structure, comprising the following steps:

[0034] Before the in-situ measurement of highly reflective metal structures, the measurement system needs to carry out pre-measurement preparations, including debugging measurement software, projectors, etc.;

[0035] Step 1: Use the camera calibration algorithm based on the planar target to calibrate the internal parameters of the left camera, right camera and projector, and calibrate the external parameters between the left camera and the right camera and the external parameters between the left camera and the projector.

[0036] First place the plane target in front of the projector and the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com