Method and device for mechanically removing sand and draining liquid from pit shaft of oil/gas well in underbalanced state

A liquid drainage device and an underbalanced technology, which are applied in the directions of driving devices for drilling in boreholes, boreholes/well components, drilling equipment and methods, etc., can solve problems such as application limitations, downhole complexity, and no liquid drainage process, etc. Achieving good economic and social benefits, avoiding formation damage, and wide practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

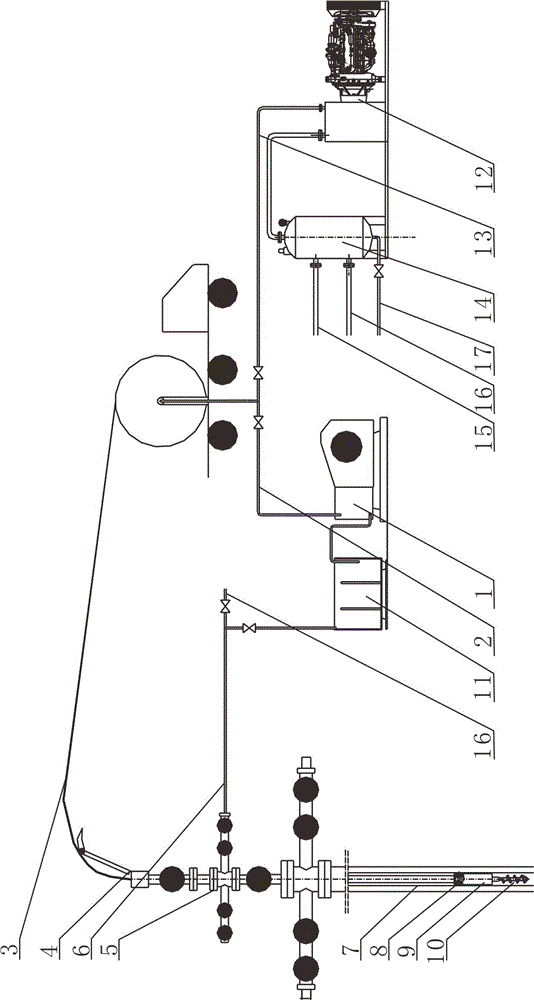

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings, but they are not further limitations on the present invention.

[0028] The invention provides a method for mechanically removing sand and draining liquid from the shaft of an oil and gas well in an under-balanced state: in an under-balanced state, the kinetic energy of the working fluid is converted into the mechanical energy of the auger bit to cut the sand body and fish out the sand. , lift the sand, and return to the ground with the working fluid to improve the sand removal efficiency and avoid the damage and pollution of the formation by the high-pressure liquid; after the sand removal is completed, inject the liquid drainage process gas into the wellbore to discharge the liquid in the wellbore, and restore the production of oil and gas wells.

[0029] The above-mentioned working fluid is a low-density working fluid. According to the composition of the formation, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com