A Double Vibration Device for Equal-stroke Asphalt Paver

A technology of vibrating device and paver, applied in the directions of roads, road repair, roads, etc., can solve the problems of negative interference of screed, unfavorable performance of paver, decline of machine performance, etc. Impact reduction, reduction of unwanted vibration effects, elimination of reciprocating inertial forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

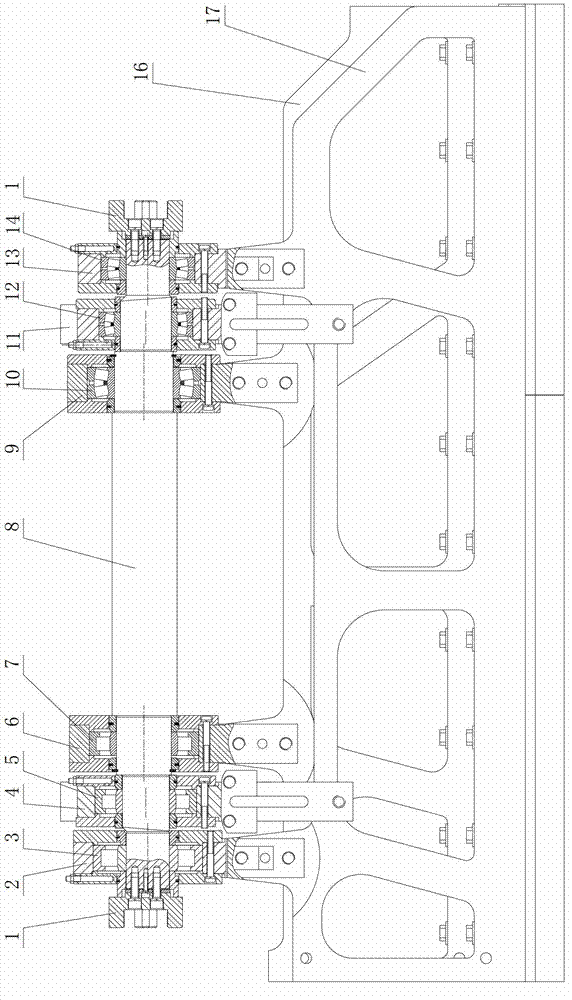

[0036] Such as figure 1 As shown, an equal-stroke asphalt paver double vibrating device includes an eccentric shaft and a front vibrating device, a rear vibrating device, a left fixed support part and a right fixed support part installed on the eccentric shaft.

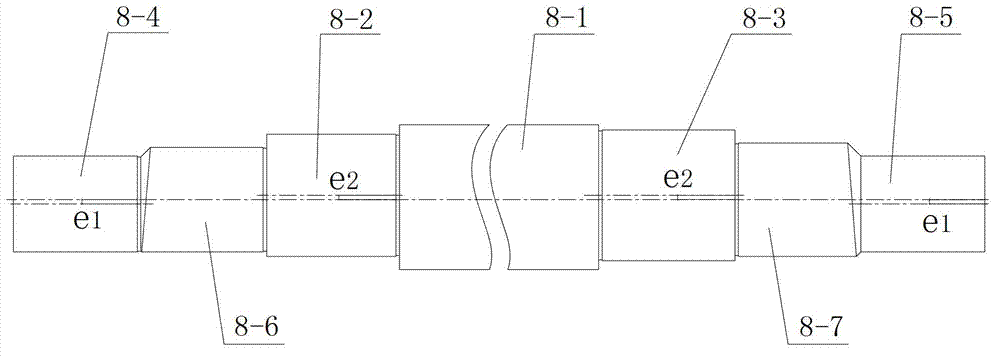

[0037] Such as figure 2As shown, the eccentric shaft includes a left outer eccentric section 8-4, a left non-eccentric section 8-6, a left inner eccentric section 8-2, and a central non-eccentric section 8-1 arranged in sequence from left to right and connected to each other. , the right inner eccentric section 8-3, the first right non-eccentric section 8-7 and the right outer eccentric section 8-5, the eccentric directions of the left outer eccentric section 8-4 and the right outer eccentric section 8-5 are the same and The eccentricity is e1, the eccentric direction of the left inner eccentric section 8-2 and the right inner eccentric section 8-3 are the same and the eccentricity is e2, the e1=e2, the left outer e...

Embodiment 2

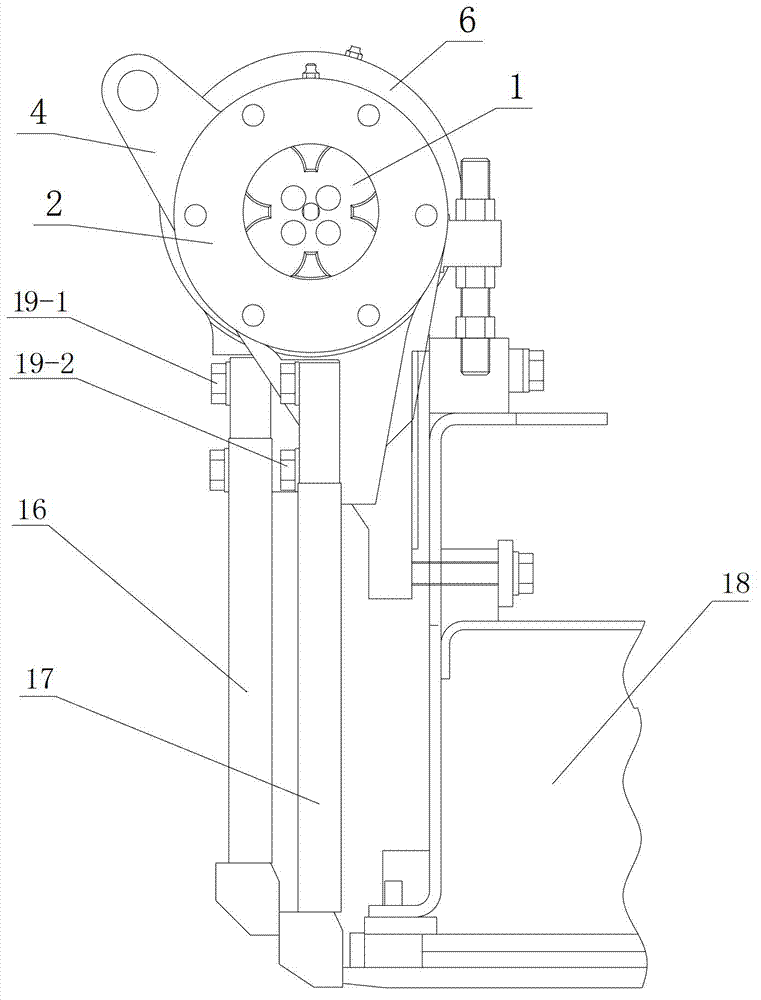

[0046] Such as Figure 4 with Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the eccentric shaft also includes a second right non-eccentric section 8-8 arranged at the right end of the right outer eccentric section 8-5, and the second right non-eccentric section Segment 8-8 connects with right outboard eccentric segment 8-5. During actual production, the left outer eccentric section 8-4, the left non-eccentric section 8-6, the left inner eccentric section 8-2, the center non-eccentric section 8-1, the right inner eccentric section 8-3, the first right The side non-eccentric section 8-7, the right outer eccentric section 8-5 and the second right non-eccentric section 8-8 are integrally formed. This embodiment is suitable for installation on the screed of the foundation section of the paver. During operation, both the left support bearing seat 4 and the right support bearing seat 11 are fixed on the screed box body 18 by bolts, and on the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com