Cold treatment and mosquito-preventing fabric and processing method thereof, and textile cold feeling finishing agent for mosquito prevention

A processing method and anti-mosquito technology, applied in fiber processing, textiles and papermaking, etc., can solve problems such as unsustainable effect, unsuitable for frequent use, human injury, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Fabric 30STK / 1 slub yarn jersey (dyed finished product)

[0023] 2. Cooling anti-mosquito finishing process:

[0024] The finishing process is: 1 dipping 1 rolling → fully drying → baking → testing indicators

[0025] Cooling finishing agent TK COOL SP-6 (manufactured by Takamatsu Oil Co., Ltd.) 100g / L;

[0026] Supporting softener YH-106RS (produced by Shanghai Linping Chemical Co., Ltd.) 40g / L;

[0027] Surplus rate: 80%;

[0028] Drying conditions: temperature: 80°C; time: 5min;

[0029] Baking conditions: temperature: 170°C; time: 1min.

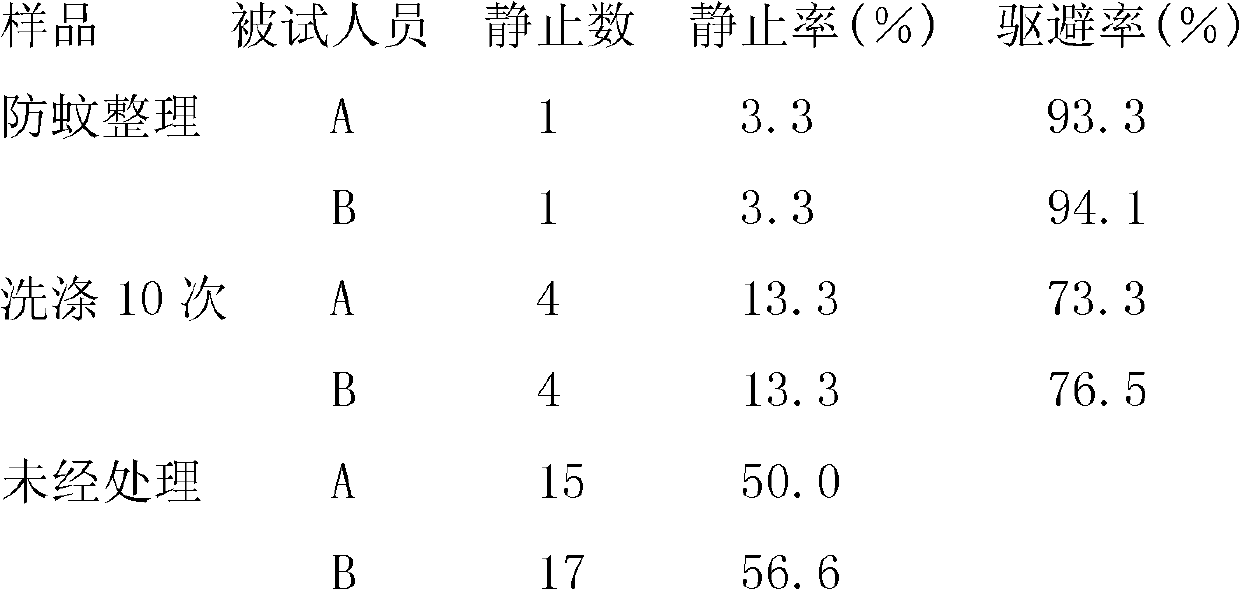

[0030] 3. Anti-mosquito performance test:

[0031] Anti-mosquito performance test method:

[0032] Put 30 mosquitoes in a mosquito breeding box (25° C.±2° C., humidity 60-70%) with a size of about 30×30×30 cm. Wrap the cloth tube around the subject's arm, and then leave it in the mosquito breeding box for 2 minutes. Test the number of mosquitoes on the arm within 2 minutes to investigate the anti-mosquito effect.

[003...

Embodiment 2

[0040] 1. Fabric 32STK / 1SZ twist + 16stk / 1 non nap twill terry (dyed finished product)

[0041] 2. Cooling anti-mosquito finishing process

[0042] The finishing process is: 1 dipping 1 rolling → fully drying → baking → testing indicators

[0043] Cooling finishing agent TK COOL SP-6 (manufactured by Takamatsu Oil Co., Ltd.) 80g / L;

[0044] Supporting softener YH-106RS (produced by Shanghai Linping Chemical Co., Ltd.) 40g / L;

[0045] Surplus rate: 85%;

[0046] Drying conditions: temperature: 100°C; time: 2min;

[0047] Baking conditions: temperature: 150°C; time: 2min.

[0048] 3. Anti-mosquito performance test:

[0049] Anti-mosquito performance testing method is the same as in Example 1.

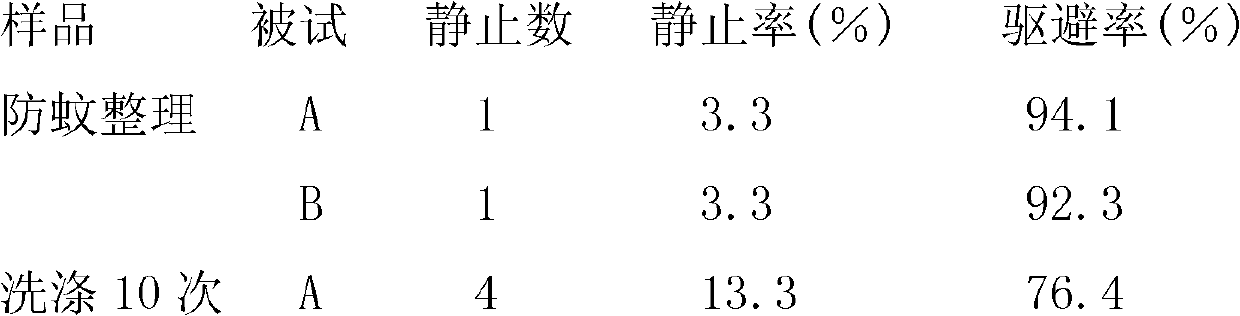

[0050] Anti-mosquito performance test results:

[0051]

[0052]

Embodiment 3

[0054] 1. Fabric 30s / 1TK organic cotton compact jersey (dyed finished product)

[0055] 2. Cooling anti-mosquito finishing process

[0056] The finishing process is: 1 dipping 1 rolling → fully drying → baking → testing indicators

[0057] Cooling finishing agent TK COOL SP-6 (manufactured by Takamatsu Oil Co., Ltd.) 50g / L;

[0058] Supporting softener YH-106RS (produced by Shanghai Linping Chemical Co., Ltd.) 40g / L;

[0059] Surplus rate: 90%;

[0060] Drying conditions: temperature: 90°C; time: 3min;

[0061] Baking conditions: temperature: 160°C; time: 2min.

[0062] 3. Anti-mosquito performance test:

[0063] Anti-mosquito performance testing method is the same as in Example 1.

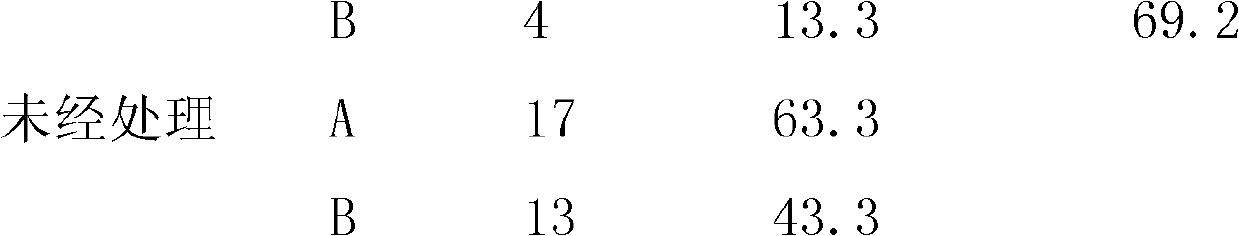

[0064] Anti-mosquito performance test results:

[0065]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com