Mechanical energy-consumption-type buffer

An energy-consuming and mechanical technology, which is applied in the field of mechanical energy-consuming elevator buffers and energy-absorbing safety collision devices, can solve the problems of high disassembly and assembly, easy damage of hydraulic oil and seals, and high price of hydraulic buffers. and other problems, to achieve the effect of simple structure and moderate impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

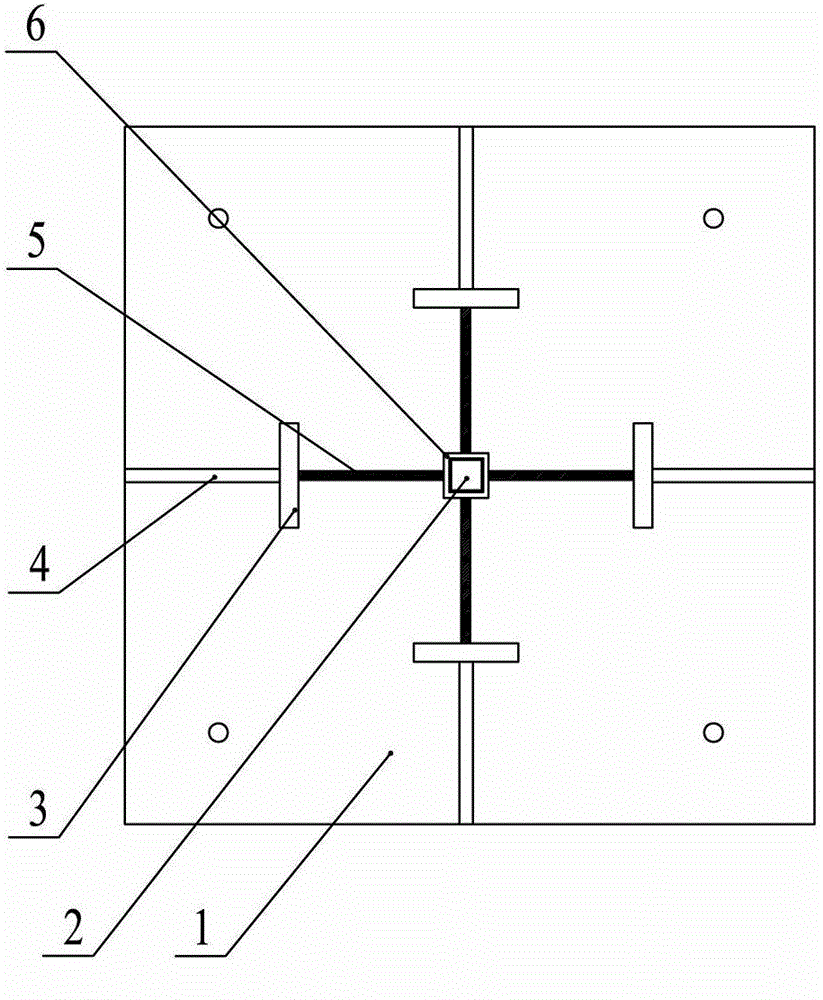

[0026] Such as Figure 1~Figure 3 As shown, the mechanical energy-dissipating elevator buffer in Example 1 is mainly composed of a bottom plate 1, a guide rod 2, a fixed plate 3, a rib plate 4, an extremely soft steel energy-dissipating damper 5, a guide groove tube 6 and a top plate 7 and other components.

[0027] Such as Figure 1~Figure 3 As shown, the guide rod 2 is vertically fixed on the bottom plate 1, and the guide groove tube 6 is movably socketed on the guide rod 2; four fixed plates evenly distributed in the circumferential direction are arranged around the guide rod 2 3. The fixing plates 3 are vertically fixed on the bottom plate 1, and each fixing plate 3 is correspondingly connected to one end of a very soft steel energy dissipation damper 5, and the other end of the very soft steel energy dissipation damper 5 is connected to the guide On the force groove pipe 6, the top plate 7 for supporting the bottom of the elevator car is fixed on the top of the force gu...

Embodiment 2

[0035] Such as Figure 6~Figure 8 As shown, the mechanical energy-dissipating elevator buffer in Embodiment 2 is mainly composed of a base plate 1, a guide rod 2, a fixed plate 3, a rib plate 4, an extremely soft steel energy-dissipating damper 5, a guide groove tube 6, and a top plate 7 and connecting plate 8 and other components, the difference from Embodiment 1 is only that: the end of the connection between the extremely soft steel energy dissipation damper 5 and the fixed plate 3 is provided with a connecting plate 8, and the connecting plate 8 is connected to the fixed plate 3. The fixing plates 3 are connected by fasteners. The advantage of this is that the installation of the entire elevator buffer is more convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com