Liftable cab of monorail crane

A cab and monorail crane technology, applied in cable railways, motor vehicles, transportation and packaging, etc., can solve the problems of inconvenient up and down, inapplicability, etc., and achieve the effect of convenient operation, simple structure and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

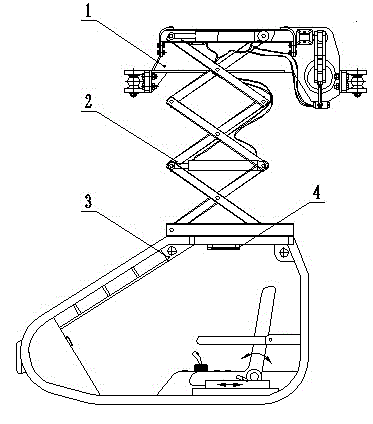

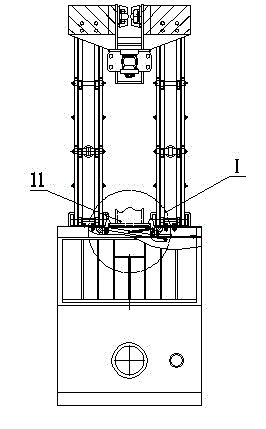

[0016] like figure 1 and figure 2 A monorail crane liftable cab is shown, including: a walking frame 1, a lifter 2 and a cab 3. The walking frame 1 above the cab 3 cooperates with the monorail crane track suspended on the roof of the coal mine roadway. That is: the walking frame 1, lifter 2, and driver's cab 3 are sequentially installed and connected from top to bottom.

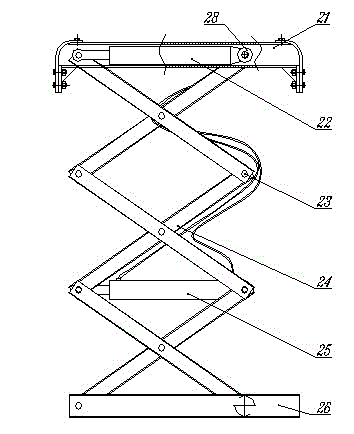

[0017] like image 3 and Figure 4 The structure of the lifter 2 shown is: two groups of telescopic arms 24 are arranged in parallel, the top of each group of telescopic arms 24 is respectively connected with an upper pulley track 21, and the bottom of each group of telescopic arms 24 is respectively connected with a lower pulley The track 26, the telescopic arm 24 is a scissor row in which two rows of multiple scissors are stacked in the vertical direction, and parallel connecting rods 23 are connected between the corresponding hinges of the two rows of scissor rows; the telescopic arm 24 One end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com