Bamboo and wood composite container bottom plate manufactured by one-step hot pressing and having high elastic modulus and manufacture method thereof

A container floor, bamboo and wood composite technology, applied in the direction of lamination devices, manufacturing tools, wood layered products, etc., can solve the problems of high labor costs, energy consumption, materials and labor, and low elastic modulus of the floor for bamboo mats. To achieve the effect of long continuous use, short cycle and fast growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

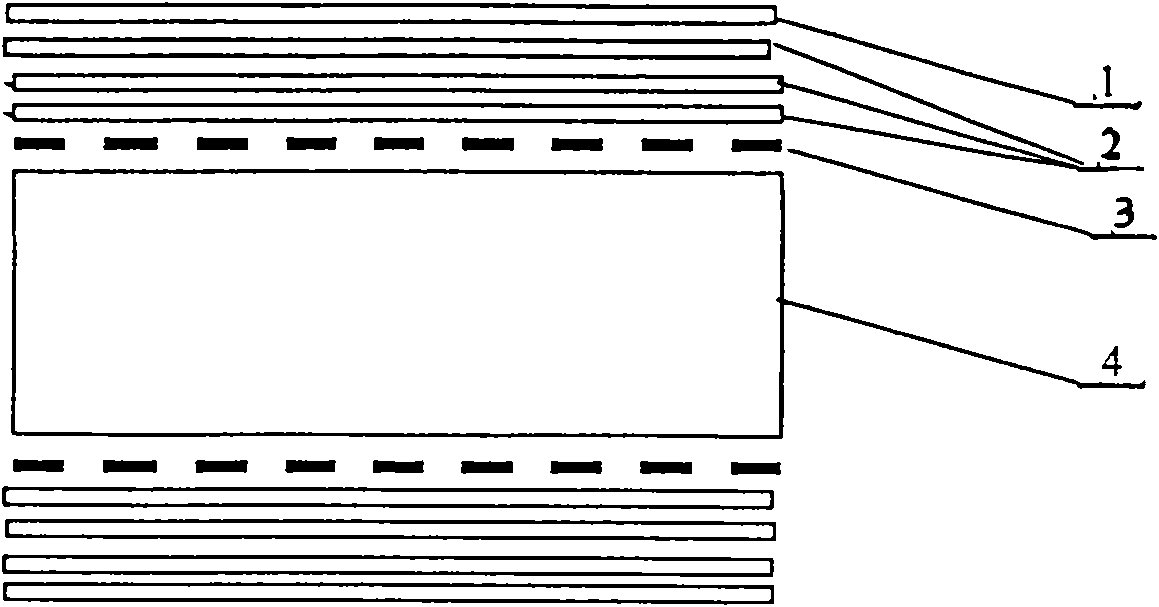

[0019] The structure of the bamboo-wood composite container floor is as follows: figure 1 ,

[0020] The manufacturing method of the bamboo-wood composite container bottom plate is as follows:

[0021] a. Sorting and finishing of wooden veneers and bamboo curtains, the moisture content of wooden veneers is ≤10%, according to the required double-sided glue coating, the glue amount is 250-350g / m 2 , aging or low-temperature drying; and dry the vertical texture thin bamboo curtain 1 and the vertical texture bamboo curtain 2 to a moisture content below 12%, and dry it at a low temperature to a moisture content below 18% after impregnating phenolic glue (or melamine glue). Add 2.4 grams of insecticide to 1 kilogram of glue (solid content 45%);

[0022] b. Particleboard core board for structure, the thickness of the particleboard substrate for structure is sanded to 20-22mm, and then used as the core board;

[0023] C. Blank assembly, from outside to inside: 1 layer of thin bambo...

Embodiment 2

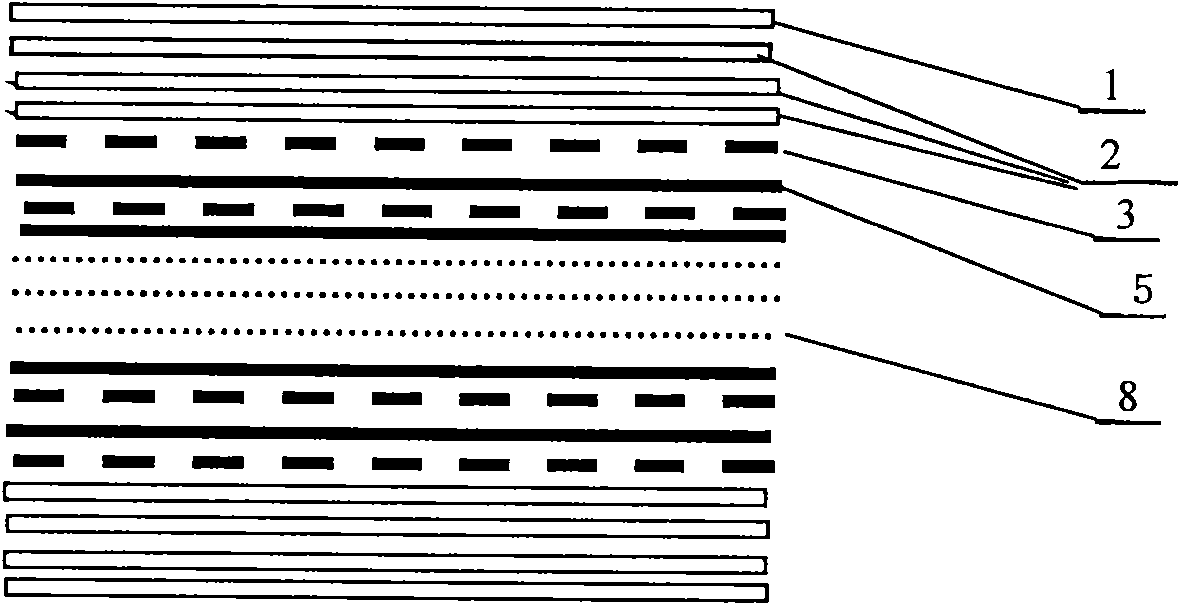

[0030] The structure of the bamboo-wood composite container floor is as follows: figure 2 ,

[0031] The manufacturing method of the bamboo-wood composite container bottom plate is as follows:

[0032] a. Sorting and finishing of wooden veneers and bamboo curtains. The moisture content of wooden veneers is ≤8%. Glue is applied on both sides according to the requirements, and the amount of glue applied is 250-350g / m 2 , aging or low-temperature drying; and dry the vertical texture thin bamboo curtain 1 and the vertical texture bamboo curtain 2 to a moisture content below 15%, and dry it to a moisture content below 20% after impregnating phenolic glue (or other weather-resistant glue). Add 2.4 grams of insecticides to 1 kilogram of glue (solid content 45%);

[0033]b. Blank assembly, from the outside to the inside: 1 layer of thin bamboo curtain with longitudinal texture impregnated with phenolic glue and dried at low temperature 1, 3 to 4 layers of bamboo impregnated with ph...

Embodiment 3

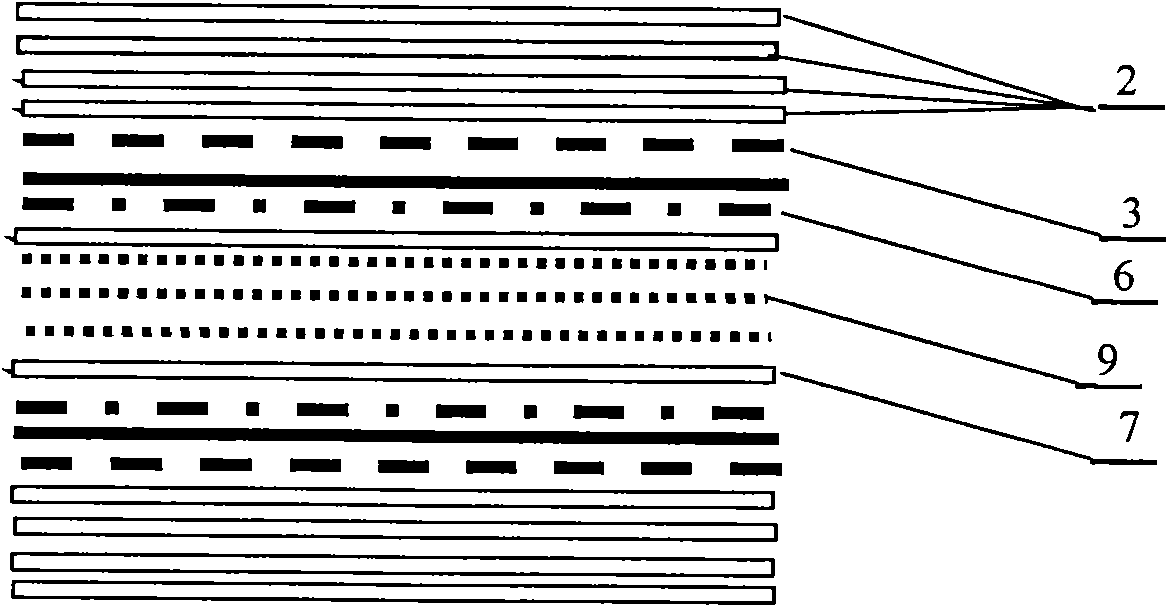

[0040] The structure of the bamboo-wood composite container floor is as follows: image 3 ,

[0041] The manufacturing method of the bamboo-wood composite container bottom plate is as follows:

[0042] a. Sorting and finishing of wooden veneers and bamboo curtains. The moisture content of wooden veneers is ≤8%. Glue is applied on both sides according to the requirements, and the amount of glue applied is 250-350g / m 2 , aging or low-temperature drying; and drying the vertical texture bamboo curtain 2, the horizontal texture bamboo curtain 6 and the longitudinal texture bamboo curtain 7 to a moisture content below 12%, and drying at a low temperature to a moisture content of 20% by impregnating phenolic glue (or melamine glue) Below, add the insecticide of 2.4 grams by 1 kilogram of glue (solid content 45%) in glue;

[0043] b. Blank assembly, from the outside to the inside: 3 to 5 layers of phenolic glue impregnated and dried at low temperature with a thickness of 1.0 to 1.5m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com