Cheese and preparation method thereof

A cheese and dry powder technology, applied in the field of cheese and its preparation, can solve problems such as poor cheese flavor, and achieve the effects of excellent taste, unique flavor and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

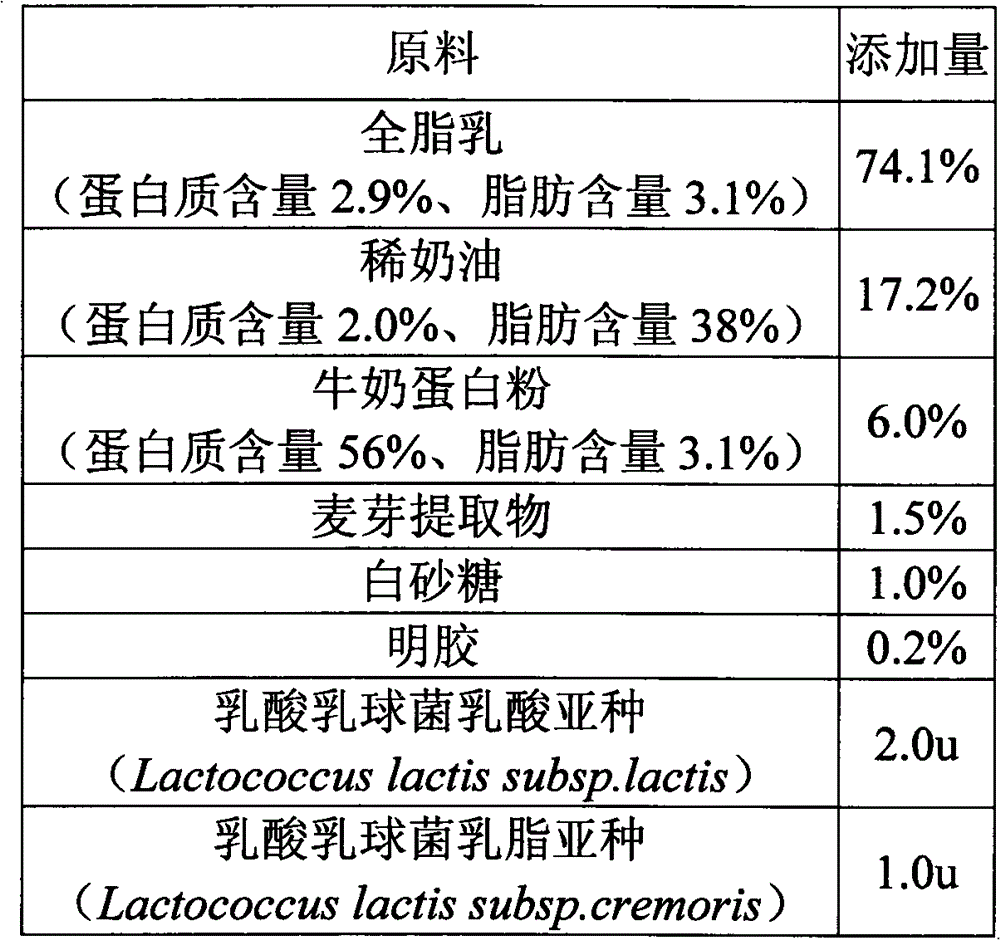

[0061] Raw material formula:

[0062]

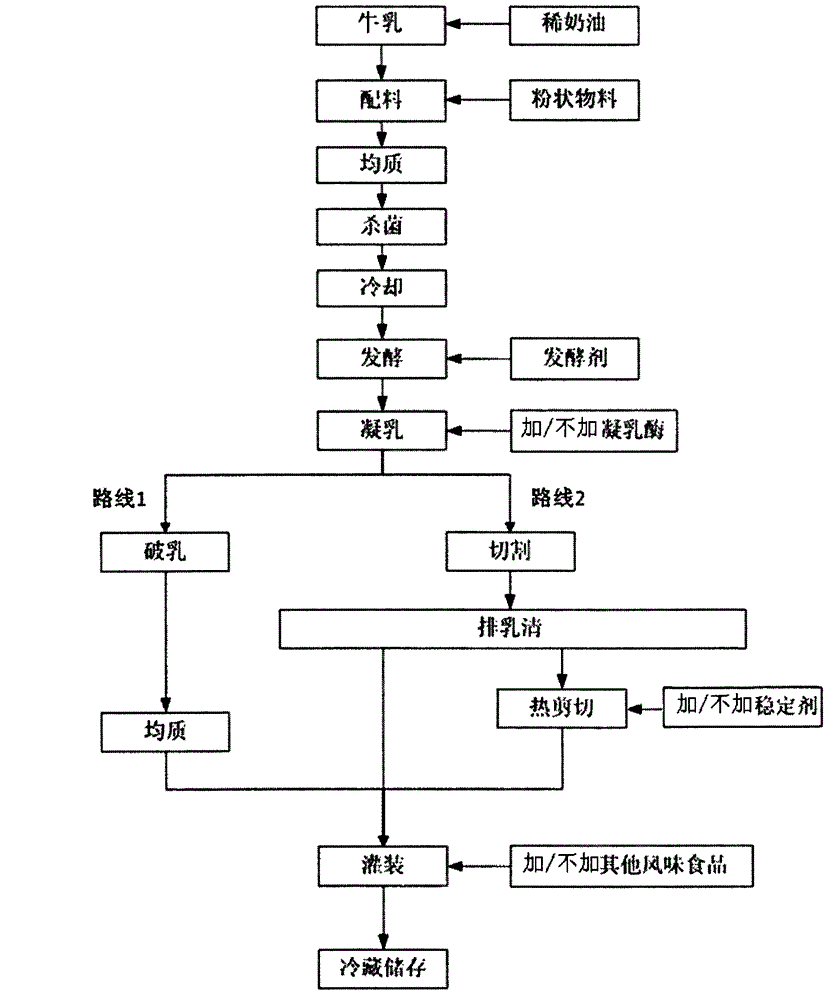

[0063] Preparation process: refer to figure 1 Route 2

[0064] (1) Mix malt extract, milk protein powder and white granulated sugar evenly to obtain a dry powder mixture;

[0065] (2) Mix whole milk and cream, slowly heat up to 50°C, and mix it with the dry powder mixture in step (1) under stirring to obtain a slurry, and stir evenly; the stirring speed is 1800rpm, and the stirring time 40min; after stirring, cool to 8°C for hydration, the hydration temperature is 8°C, and the hydration time is 45min;

[0066] (3) Raise the temperature of the above slurry to 65°C for homogenization, the temperature of homogenization is 65°C, and the pressure of homogenization is 150bar; sterilization, the temperature of sterilization is 80°C, and the time of sterilization is 15s; after cooling to 30°C;

[0067] (4) Fermenting the above-mentioned slurry and starter, the temperature of fermentation is 30°C, the time of fermentation is 15h, and the e...

Embodiment 2

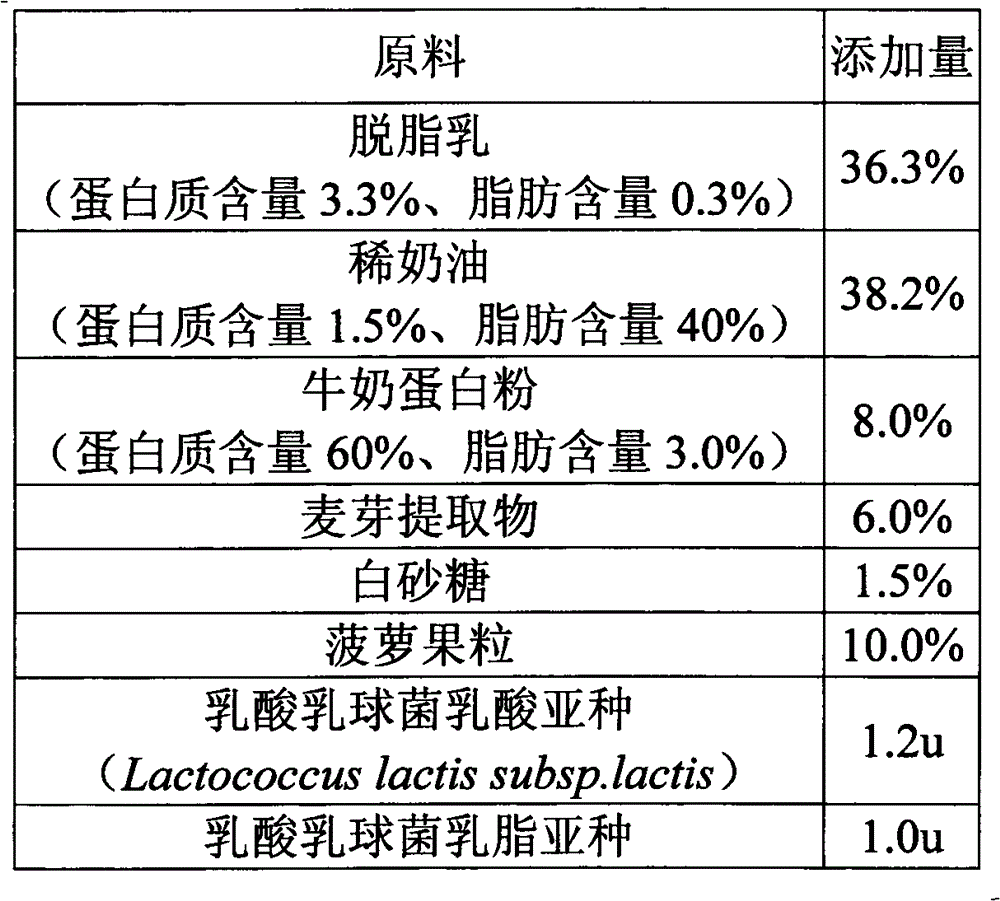

[0072] Raw material formula:

[0073]

[0074]

[0075] Preparation process: refer to figure 1 Route 1

[0076] (1) Mix malt extract, milk protein powder and white granulated sugar evenly to obtain a dry powder mixture;

[0077] (2) Mix skim milk and cream, slowly heat up to 50°C, and mix it with the dry powder mixture in step (1) under stirring conditions to obtain a slurry, and stir evenly; the stirring speed is 2200rpm, and the stirring time is 20min; after stirring, cool to 4°C for hydration, the hydration temperature is 4°C, and the hydration time is 70min;

[0078] (3) Raise the temperature of the above slurry to 60°C for homogenization, the temperature of homogenization is 60°C, and the pressure of homogenization is 50 bar; sterilization, the temperature of sterilization is 85°C, and the time of sterilization is 300s; after cooling to 29°C;

[0079] (4) Ferment the above-mentioned slurry and starter, the temperature of fermentation is 29°C, the time of ferment...

Embodiment 3

[0083] Raw material formula:

[0084]

[0085]

[0086] Preparation process: refer to figure 1 Route 2

[0087] (1) uniformly mixing malt extract, milk protein powder, whole milk powder and white granulated sugar to obtain a dry powder mixture;

[0088] (2) Mix whole milk and cream, slowly heat up to 45°C, and mix it with the dry powder mixture in step (1) under stirring conditions to obtain a slurry, and stir evenly; the stirring speed is 2000rpm, and the stirring time for 20 minutes; after stirring, cool to 2°C for hydration, the hydration temperature is 2°C, and the hydration time is 30 minutes;

[0089] (3) Raise the temperature of the above slurry to 55°C, homogenize, the temperature of homogenization is 55°C, and the pressure of homogenization is 200bar; sterilization, the temperature of sterilization is 85°C, and the time of sterilization is 300s; after cooling to 35°C;

[0090] (4) Mix and ferment the above slurry and starter, the fermentation temperature is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com