Method of driving non-volatile logic circuit and non-volatile logic circuit

A logic circuit, non-volatile technology, applied to logic circuits using basic logic circuit components, logic circuits using specific components, logic circuits with logic functions, etc., can solve problems such as short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0100] (Structure of the nonvolatile logic circuit 20)

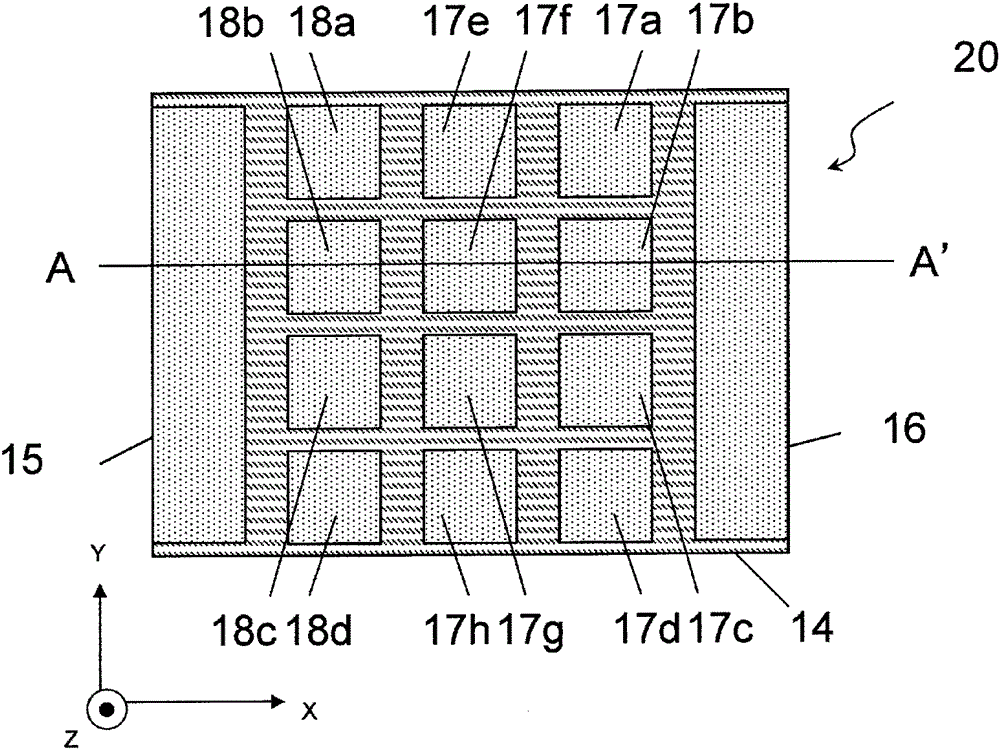

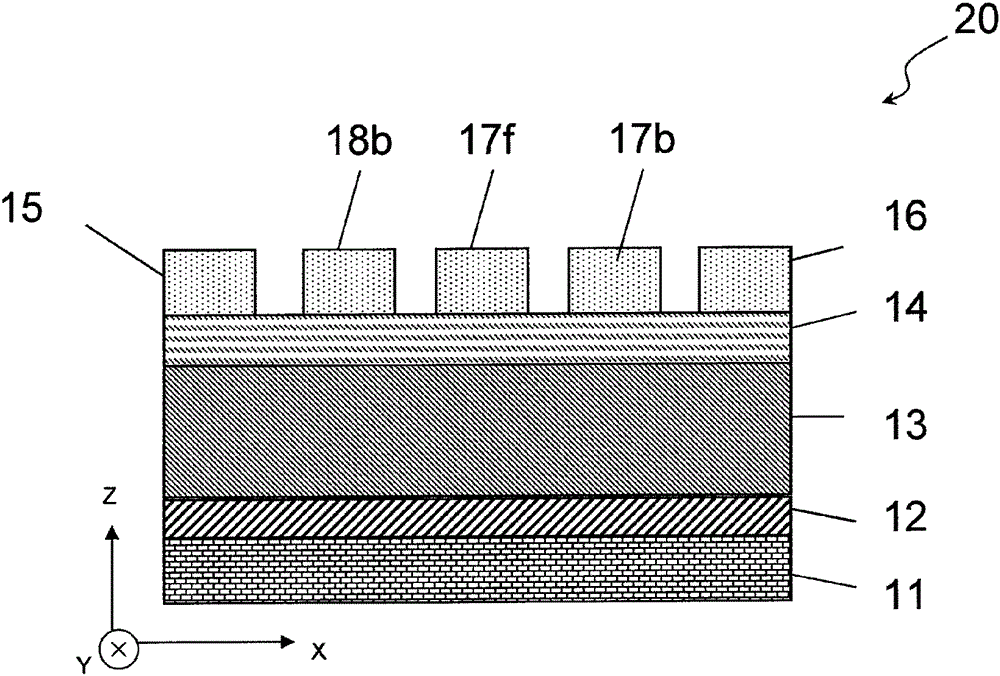

[0101] Figure 1A A plan view of the nonvolatile logic circuit 20 according to Embodiment 1 is shown. Figure 1B express Figure 1A The cross-sectional view of A-A' in.

[0102] like Figure 1B As shown, a control electrode 12 , a ferroelectric film 13 , a semiconductor film 14 , and electrode groups 15 to 18 are sequentially stacked on a substrate 11 .

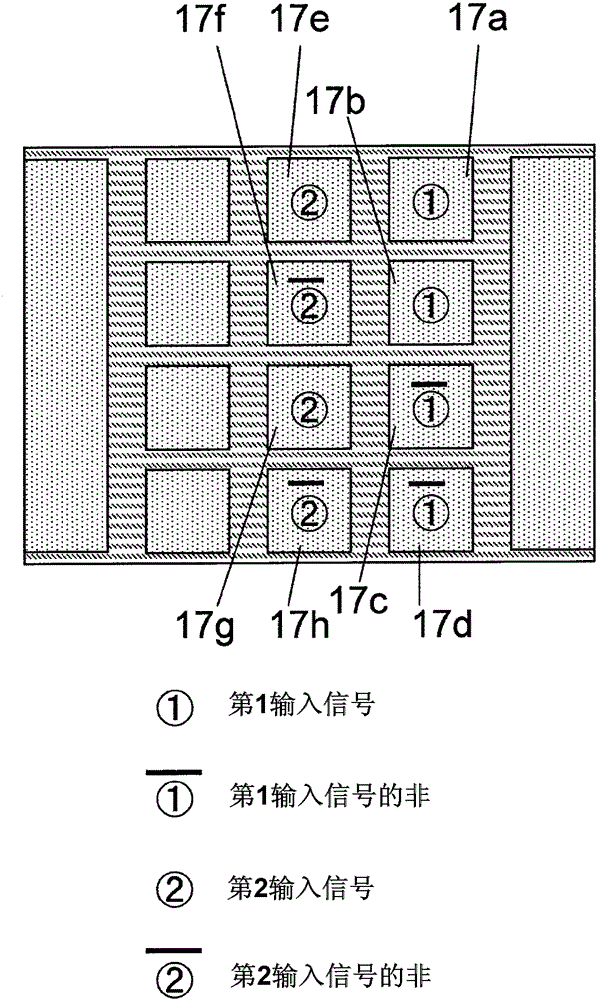

[0103] The electrode group has a power supply electrode 15, an output electrode 16, first to eighth input electrodes 17a to 17h, and first to fourth logic setting electrodes 18a to 18d.

[0104] like Figure 1A and Figure 1B As shown, the X direction, the Y direction, and the Z direction are the longitudinal direction, the direction perpendicular to the longitudinal direction, and the stacking direction of the ferroelectric film (13), respectively.

[0105] Along the X direction, the first to eighth input electrodes 17 a to 17 h and the first to fourth logic set...

Embodiment 1

[0199] (1) On the silicon substrate 11 having a surface covered with a silicon oxide film, a titanium film having a thickness of 5 nm and a platinum film having a thickness of 30 nm were sequentially formed using an electron gun evaporation method. Furthermore, SrRuO with a thickness of 10 nm was formed by pulsed laser deposition 3 (hereinafter referred to as SRO) film. In this manner, control electrode 12 is formed on silicon substrate 11 .

[0200] (2) The substrate was heated to 700°C. In the PLD cavity, a Pb(Zr,Ti)O 3 constituted ferroelectric film 13.

[0201] (3) The temperature of the substrate was set to 400° C., and a semiconductor film 14 made of ZnO was formed to have a thickness of 30 nm in the PLD chamber.

[0202] (4) On the semiconductor film 14, a resist pattern is formed by photolithography. Thereafter, portions of the semiconductor film 14 not covered with the resist are removed by etching using nitric acid.

[0203] (5) On the semiconductor film 14, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com