Thermal setted coextruded heat shrinkable sleeving and method for producing same

A technology of heat shrinkable sleeve and manufacturing method, which can be applied to insulators, electrical components, circuits, etc., and can solve problems such as reliability reduction, sealing failure, vibration shedding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Specific embodiments of the present invention are described with reference to the above drawings.

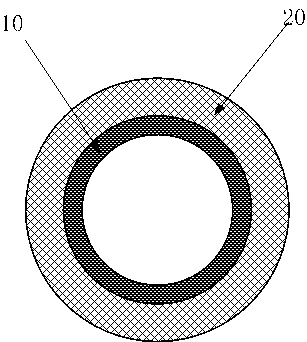

[0013] Depend on figure 1 It can be seen from the figure that this thermosetting composite heat-shrinkable sleeve includes a reactive hot-melt adhesive layer 10 in the inner layer, and the outer layer is a heat-shrinkable layer 20 whose main material is thermoplastic polyolefin, and the main material is thermoplastic The components of the polyolefin heat-shrinkable layer 20 are proportioned by volume: 55-80 parts of low-density or medium-density polyethylene; 15-30 parts of modified materials; 5-15 parts of additives.

[0014] Among them, the components of 15-30 parts of the modified material are distributed according to the volume ratio of 5-10 parts of EPDM rubber and 10-20 parts of polyolefin elastomer. The index of polyolefin elastomer is: the melt index is 1.5-5.0, The VA content is 14-28%.

[0015] The auxiliary agent is carbon black, flame retardant, sensitizer, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com