Segmental loaded tunneling testing apparatus of full-face tunnel boring machine

A full-face roadheader and segmented loading technology, which is applied in soil material testing, material inspection products, etc., can solve the problem of comprehensive tunneling tests, inability to complete slag discharge, grouting, receiving, and large deviations between test data and engineering reality. problems, to achieve the effect of avoiding movement, firm structure, and safe and reliable test process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

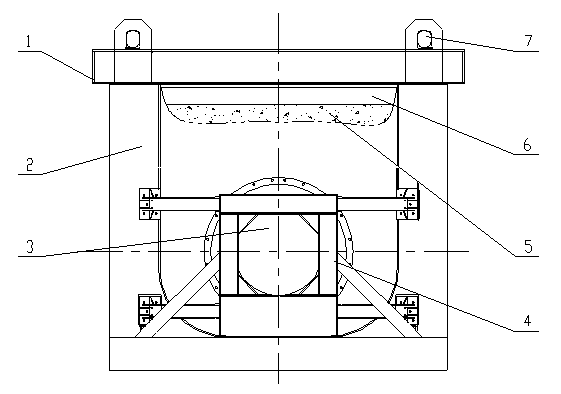

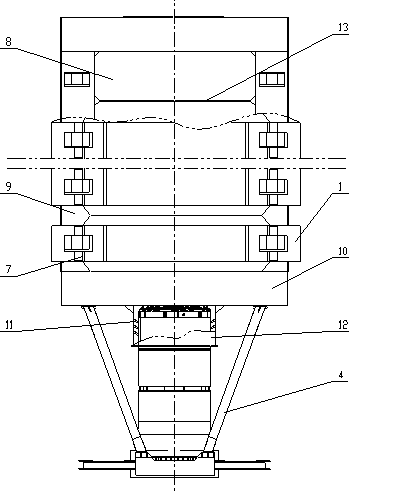

[0010] With reference to the accompanying drawings, a full-section roadheader segmental loading tunneling test device is composed of a loading beam 1, a test box 2, a full-section roadheader 3, a reaction frame 4, a simulated formation medium 5, a segmental loading water bag 6, a lock tight pin 7, arc base 8, side wall 9, end cover 10, seal brush 11, guide pipe 12, pressure spacer beam 13, fill and tamp the simulated formation medium 5 in the test box 2, and bury the soil pressure, Water pressure sensor, 8 sets of segmented loading water bladders 6 are installed separately with 7 pressure-bearing partition beams 13; test box 2 is composed of arc base 8, left and right side walls 9 and front and rear end covers 10, which is an integral welded structure. 8 loading beams 1 for carrying the reaction force of segmented loading water bag 6 are installed on 2 through locking pin 7, the reaction force frame 4 is fixed with the end cover 10 of the test box 2 by bolts, and the full-secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com