Barrier fluid circulation system for mechanical seals

A mechanical seal and circulation system technology, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve problems such as changes, pressure cannot be adjusted accordingly, sealing medium leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

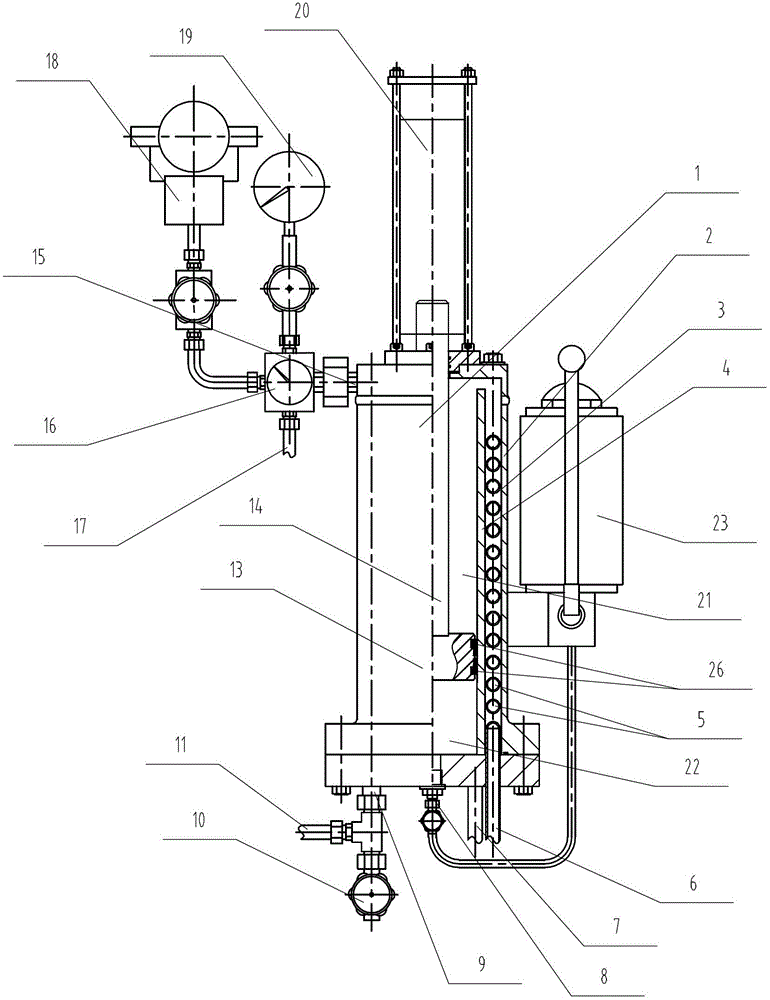

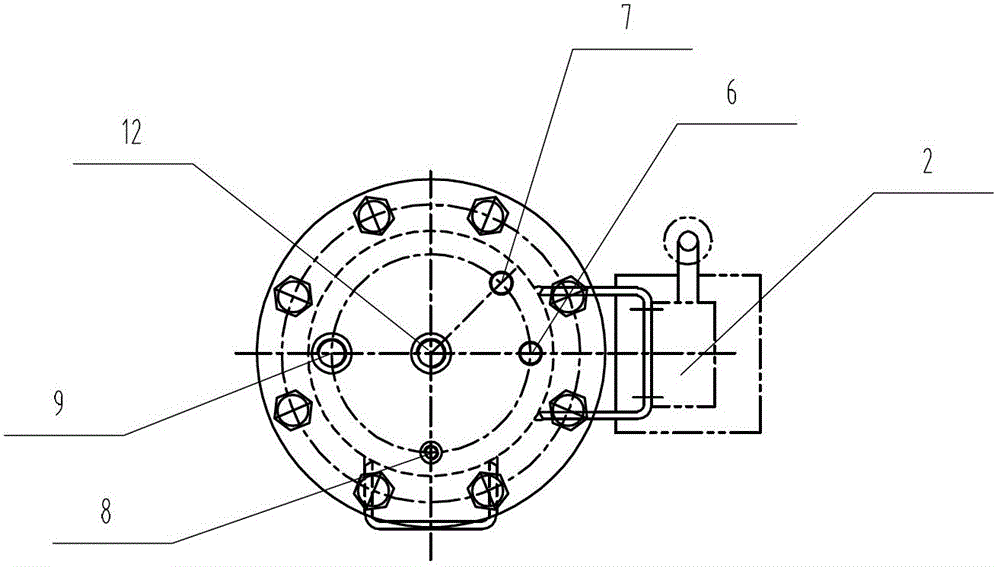

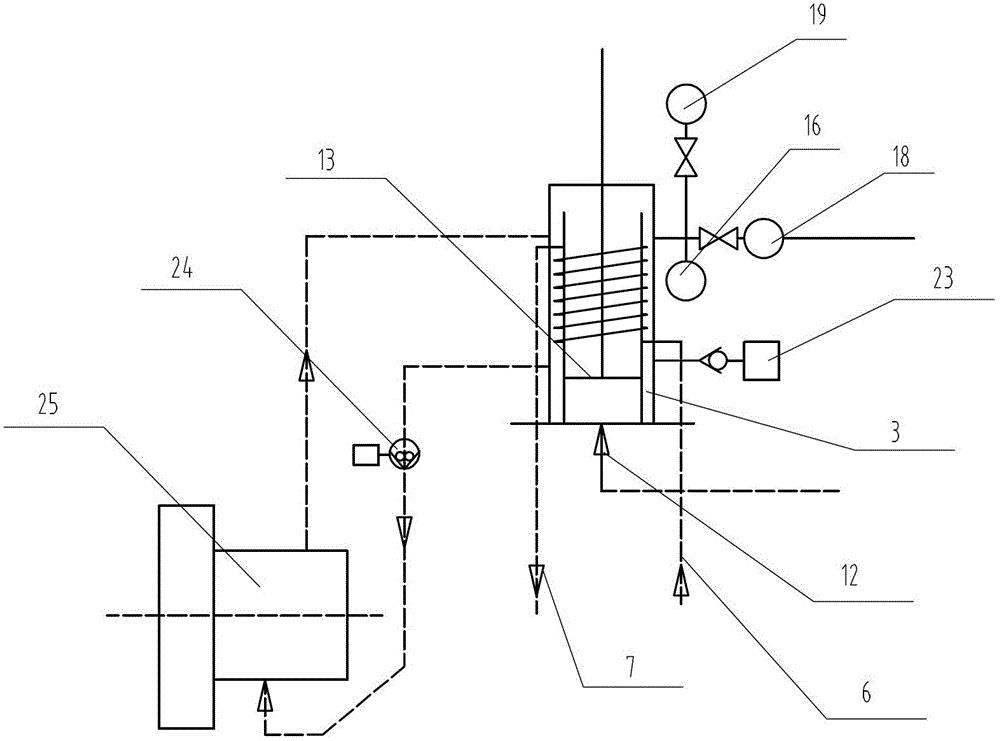

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0020] combined with figure 1 to attach image 3, an isolation liquid circulation system for mechanical seals, which includes a liquid storage tank, the liquid storage tank includes a tank body 1, the tank body 1 is provided with a liquid replenishment port, a liquid outlet 9 and a liquid inlet 15, and the outlet The liquid port 9 and the liquid inlet port 15 form a circulation circuit through the pipeline and the mechanical seal cavity 25 on the mechanical seal for containing the spacer liquid. The tank body 1 is a hollow structure with both ends sealed, and the tank body 1 is also equipped with A tubular interlayer wall 4 that separates the tank body 1 into two inner and outer chambers, the outer chamber is the interlayer chamber 3, and the inner main chamber 21 is equipped with a piston 13. The piston 13 is sealed The ring 26 divides the main chamber 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com