Axial positioning and connecting structure of cam shaft

A technology of axial positioning and connection structure, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of poor economy, poor adjustment of pressure plate manufacturing, and large amount of pressure plate scrapping, so as to improve economic benefits and improve manufacturability , The effect of reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with specific drawings and embodiments.

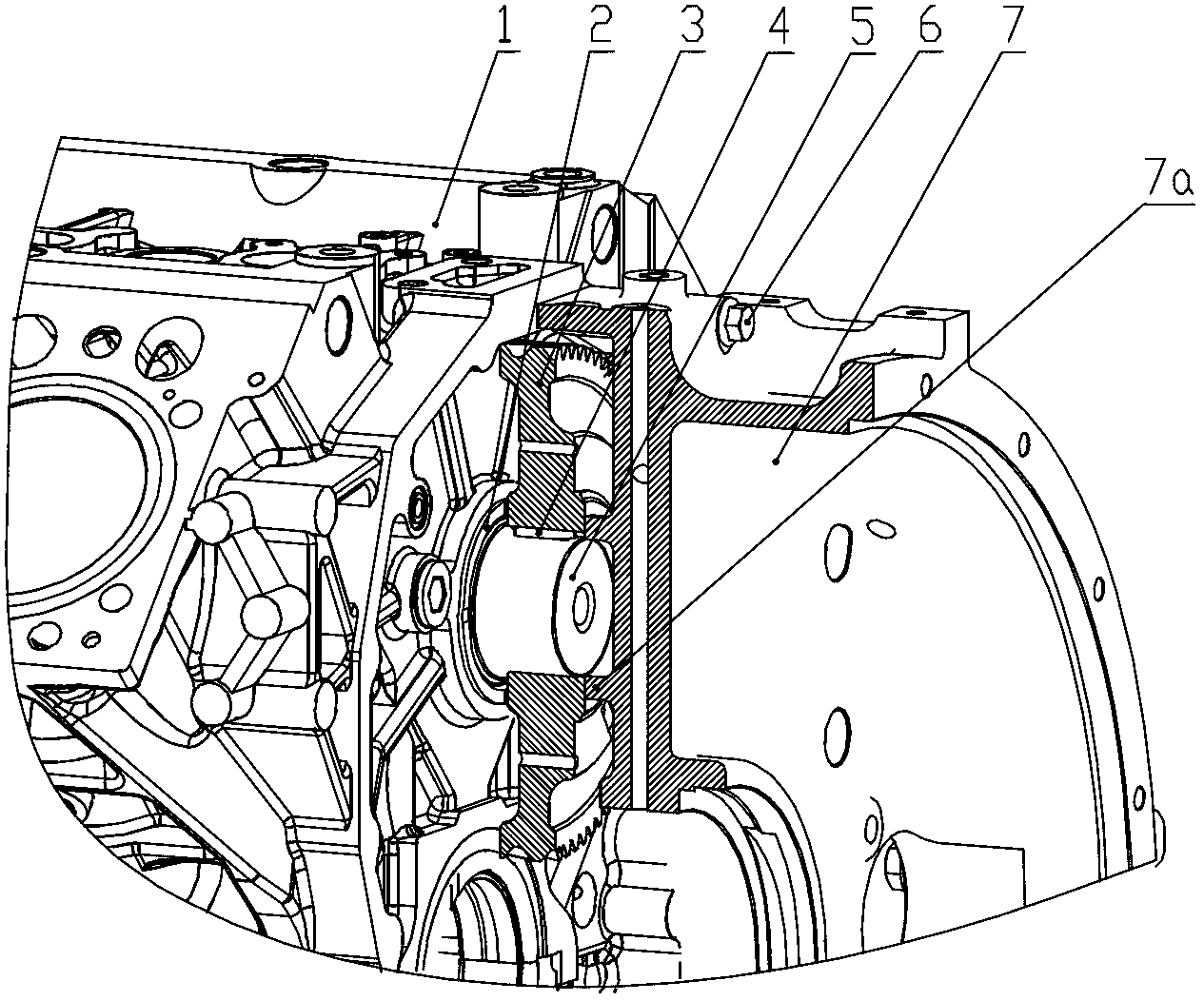

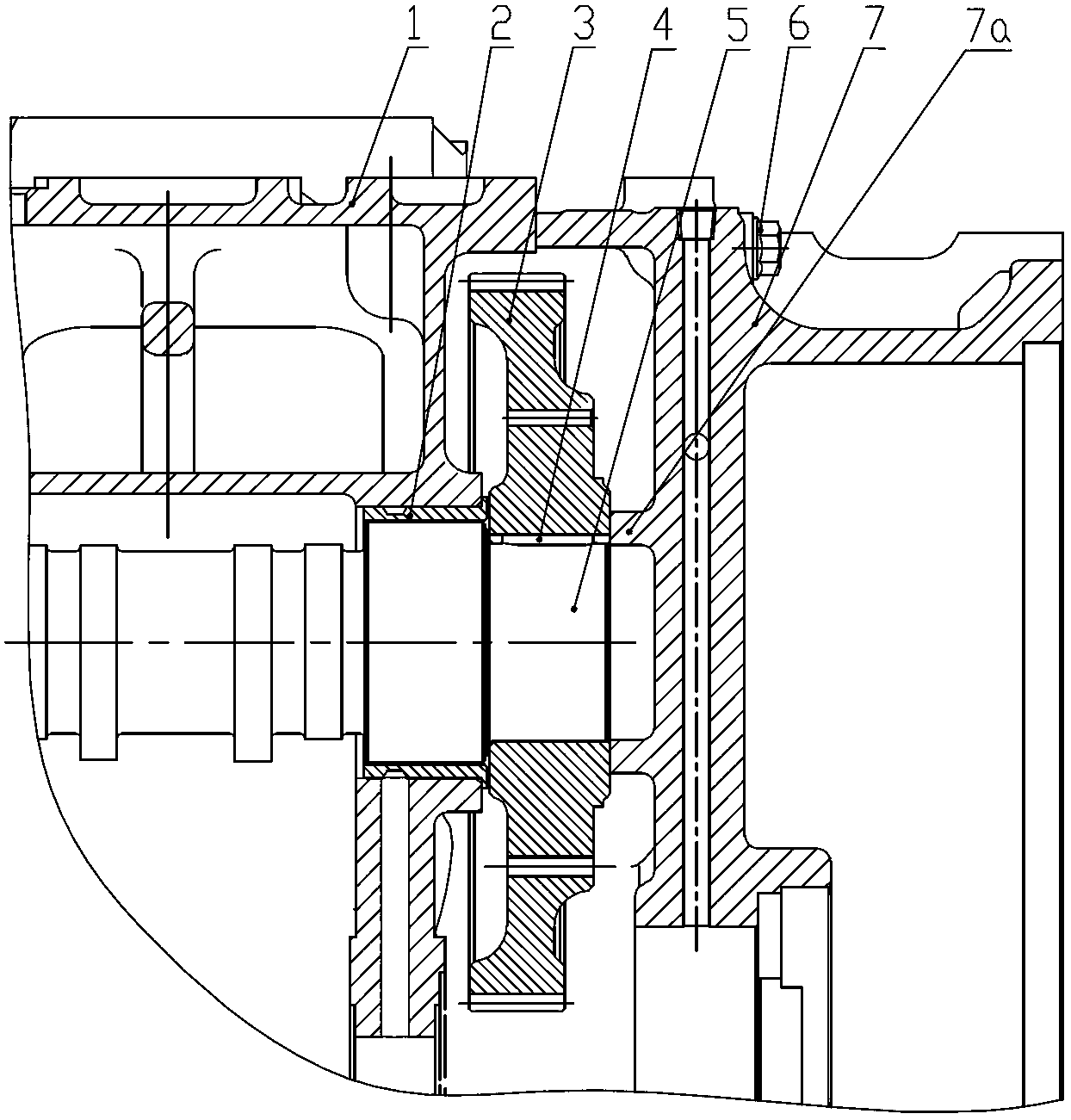

[0010] As shown in the figure: the camshaft axial positioning connection structure in the embodiment is mainly composed of an independent body 1, a camshaft thrust bush 2, a timing gear 3, a flat key 4, a camshaft 5, and a flywheel housing fastening bolt 6 Composed of components such as the flywheel housing 7, the independent body 1 in the embodiment is the body of a water-cooled engine.

[0011] Such as figure 1 , figure 2 As shown, the camshaft 5 is rotatably installed in the independent body 1, the timing gear 3 is installed on the camshaft 5 and connected to the transmission with the flat key 4, and the flywheel housing 7 is fastened to the independent body by the fastening bolt 6 of the flywheel housing. 1; the side of the flywheel housing 7 opposite to the timing gear 3 is provided with an axial positioning block 7a, and the axial positioning block 7a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com