Shoe pad and making method thereof

A production method and insole technology, applied in the field of polyurethane insole and its production, can solve the problems of discomfort, insole sliding, inconvenient walking, etc., and achieve the effect of convenient production and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

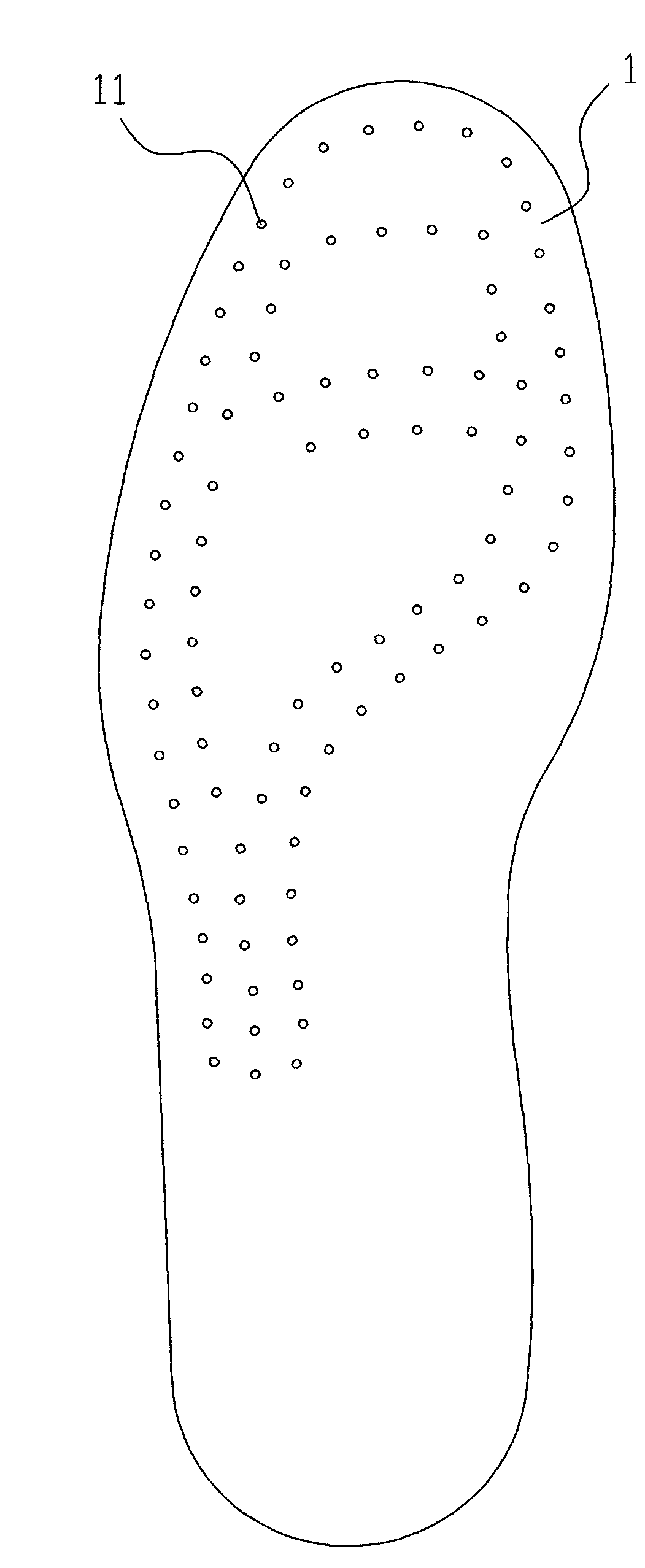

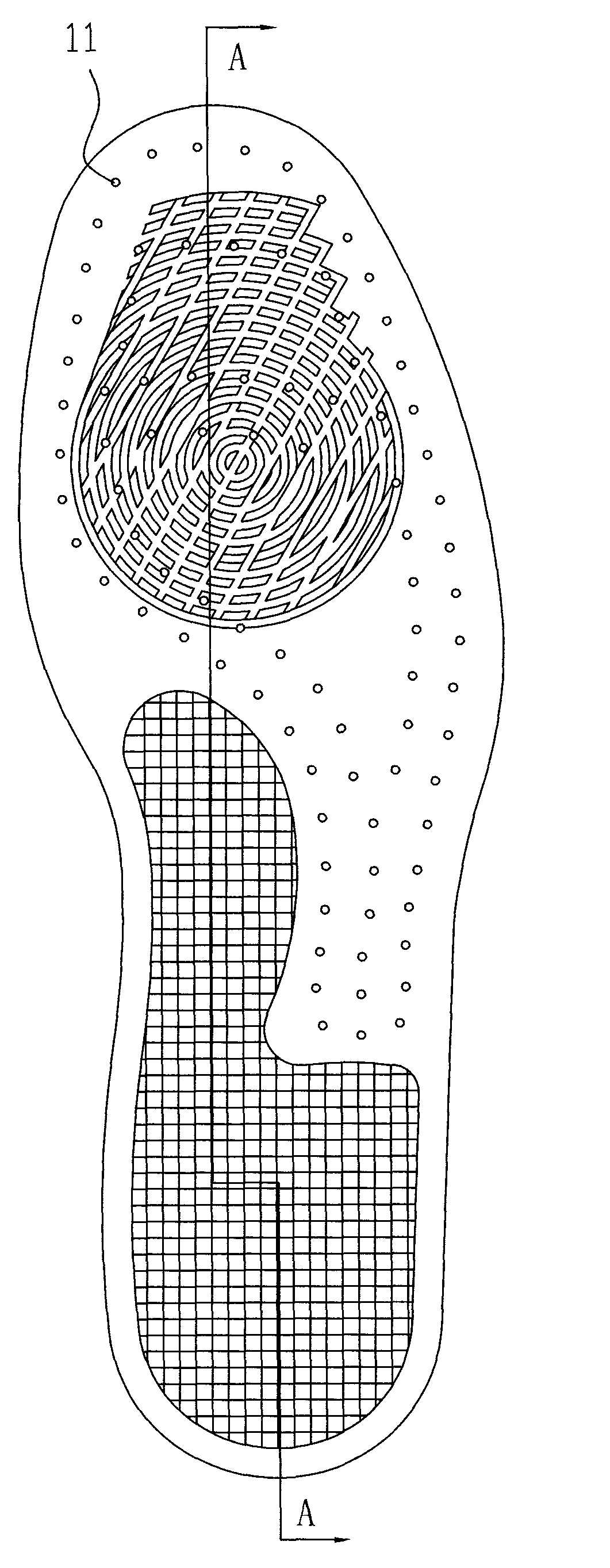

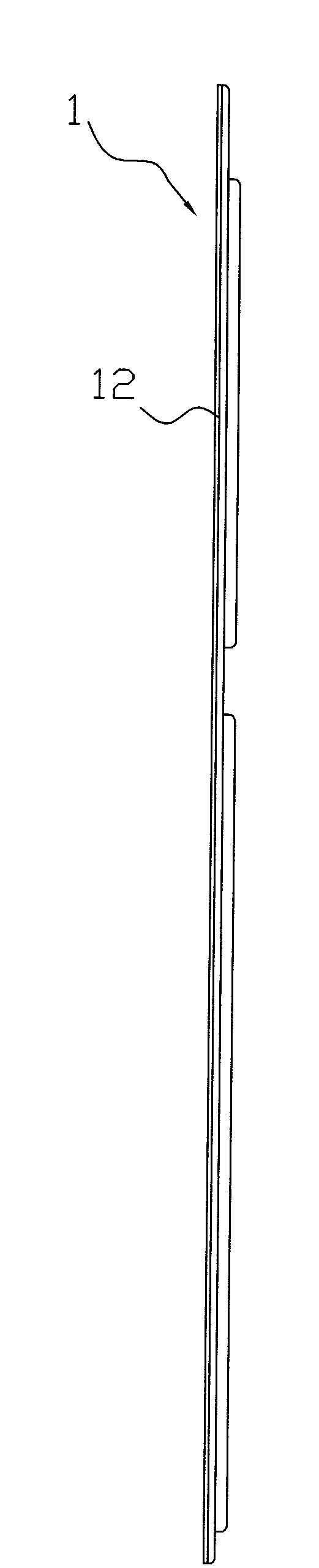

[0028] Example one, such as Figure 1 to Figure 10 As shown, the manufacturing method of the insole of this embodiment sequentially includes the following steps:

[0029] 1. Raw materials and ingredients: Select the insole surface layer cloth 12 as the raw material, and place the ingredients as component a and component b. The composition of component a is: polyether polyol 50%, polyester polyol 37%, Butanediol 1%, Hexanediol 1%, Dipropylene glycol 1%, Stannous octanate 1%, Dibutyltin dilaurate 1%, Bismuth isooctanoate 1%; Triisopropanolamine 1%, Trihydroxypropane 1 %, silicone oil 5%; the composition of component b is: polyether polyol 40%, polycarbonate diol 22%, isocyanate 30%, adipyl chloride 0.1%, phosphoric acid 0.1%, oleic acid 0.1%, butane Diol 0.7%, neopentyl glycol 3%, hexanediol 4%, the above is the weight percentage.

[0030] 2. Open the hinged mold 2 and spray the release agent on the inner surface of the upper mold body 21, and at the same time place the insole surf...

Embodiment 2

[0033] Embodiment two, such as Figure 1 to Figure 10 As shown, the manufacturing method of the insole of this embodiment sequentially includes the following steps:

[0034] 1. Raw materials and ingredients: Select the insole surface layer cloth 12 as the raw materials, and place the ingredients as component a and component b respectively. The composition of component a is: polyether polyol 60%, polyester polyol 30%, Butanediol 1.25%, Hexanediol 0.75%, Dipropylene glycol 0.5%, Stannous octanate 0.5%, Dibutyltin dilaurate 1.5%, Bismuth isooctanoate 1.5%; Triisopropanolamine 0.5%, Trihydroxypropane 0.5% %, silicone oil 3%; the composition of component b is: polyether polyol 50%, polycarbonate diol 25%, isocyanate 20%, adipyl chloride 0.05%, phosphoric acid 0.03%, oleic acid 0.07%, butyl Glycol 0.85%, neopentyl glycol 2%, hexanediol 2%, the above is the weight percentage.

[0035] 2. Open the mold 2 which is opened up and down, spray the mold release agent on the inner surface of th...

Embodiment 3

[0038] Example three, such as Figure 1 to Figure 10 As shown, the manufacturing method of the insole of this embodiment sequentially includes the following steps:

[0039] 1. Raw materials and ingredients: select the insole surface layer cloth 12 as the raw material, and place the ingredients as component a and component b respectively. The composition of component a is: polyether polyol 50%, polyester polyol 46%, Butanediol 1.5%, Hexanediol 0.5%, Dipropylene glycol 1.16%, Stannous octanol 0.1%, Dibutyltin dilaurate 0.1%, Bismuth isooctanoate 0.09%; Triisopropanolamine 0.2%, Trihydroxypropane 0.25 %, silicone oil 0.1%; the basic composition of component b is: polyether polyol 60%, polycarbonate diol 30%, isocyanate 5%, adipyl chloride 0.1%, phosphoric acid 0.1%, oleic acid 0.1%, Butanediol 2%, neopentyl glycol 0.2%, hexanediol 2.5%, the above is the weight percentage.

[0040] 2. Open the hinged mold 2 and spray the release agent on the inner surface of the upper mold body 21, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com