Ultrahigh-strength high-hardenability Al, Zn, Mg and Cu alloy

An al-zn-mg-cu, high hardenability technology, applied in the field of metal alloys, can solve the problems of difficult to meet demand, large differences in the performance of the surface and the core of the product, and the amount of Er added cannot be too high, so as to reduce quenching. effect of sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

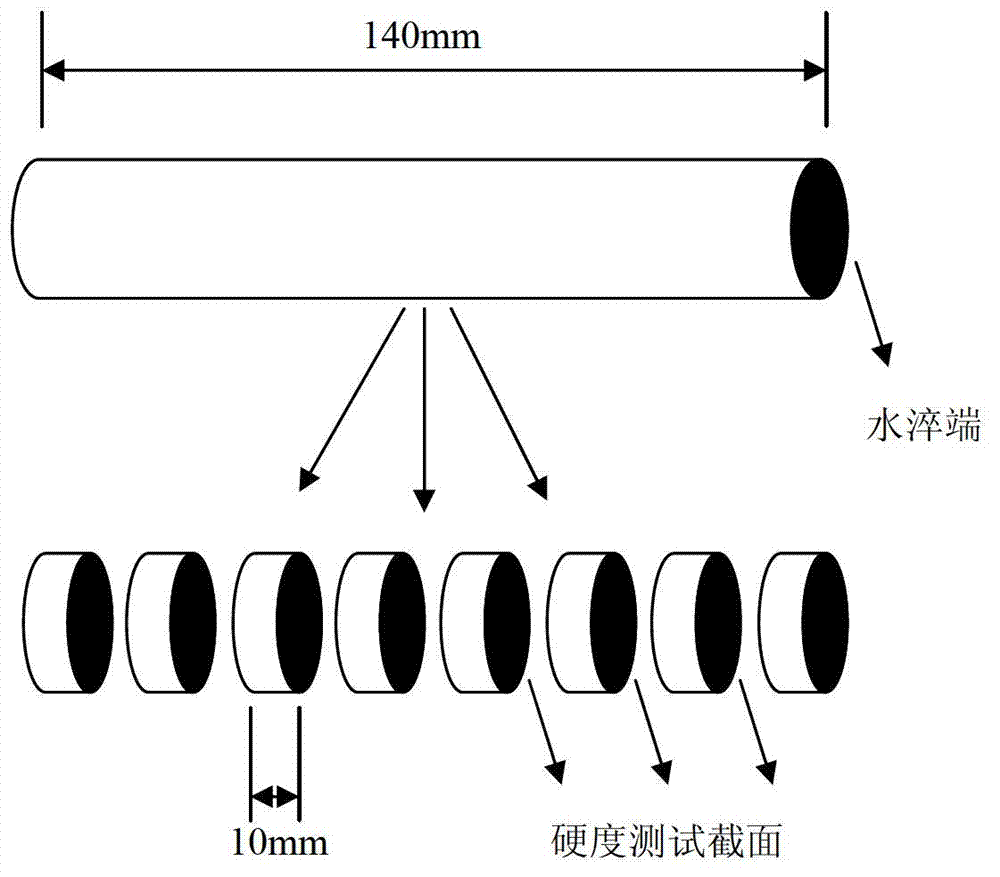

[0037] The bar of alloy Al-10.0Zn-1.6Mg-1.4Cu-0.12Zr was treated in the same way, and its end quenching hardness value was obtained as shown in Table 3. The hardness of the water-quenched end is 209HV, the hardness of the most distal end is 186HV, the absolute value of the hardness decrease is 23, the decrease percentage is 11.0%, and the single-end hardening depth is about 82mm.

[0038] Table 3 Al-10.0Zn-1.6Mg-1.4Cu-0.12Zr end quenching hardness test results

[0039]

[0040] The end quenching curve of comparative example 1 alloy is shown in Figure 4 , the end quenching curve of the comparative example 2 alloy is shown in Figure 5 , the end quenching curve of the alloy of the present invention is shown in Image 6 , the comparison of the end quenching curves of the three alloys is shown in Figure 7 .

[0041] The three alloys are within the effective hardness range (hardness loss 10%), the depth of Comparative Example 1 and Comparative Document 2 is 60mm, while the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com