High-efficiency low-foam type degreasing agent

A degreasing agent, high-efficiency technology, applied in the direction of leather degreasing, detergent composition, surface active detergent composition, etc., to achieve the effect of removing fiber interstitial and high-efficiency degreasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add 34.1 g of fatty alcohol polyoxyethylene ether and 11.3 g of alkyl glycoside into the beaker, mix and stir evenly, and stir at a stirring speed of 100 r / min for 30 min. After adding 55.7 g of deionized water, stir for 30 minutes to obtain the product of the present invention.

Embodiment 2

[0032] Add 25g of fatty alcohol polyoxyethylene ether and 20g of alkyl glycoside into the beaker, mix and stir evenly, and stir at a stirring rate of 100r / min for 30min. After adding 55 g of deionized water, stir for another 30 minutes to obtain the product of the present invention.

Embodiment 3

[0034] Add 45 g of fatty alcohol polyoxyethylene ether and 55 g of deionized water, and then stir for 30 minutes at a stirring rate of 100 r / min to obtain the product of the present invention.

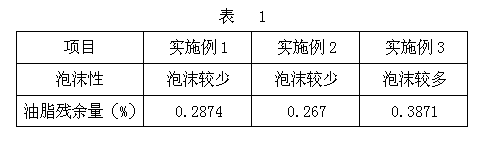

[0035] According to the product of above-mentioned preparation, carried out application comparative test, its result is as follows table 1:

[0036]

[0037] From the above test results, it can be seen that the synergistic effect of fatty alcohol polyoxyethylene ether and alkyl glycoside can effectively inhibit the generation of foam, and can make leather products achieve excellent degreasing effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com