Method for extracting macadimia nut oil

A technology of argan oil and nuts, which is applied in the direction of fat oil/fat production and fat generation, can solve the problems of extraction of macadamia nut oil that have not been reported, and achieve the effects of shortening extraction time, avoiding oxidation, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

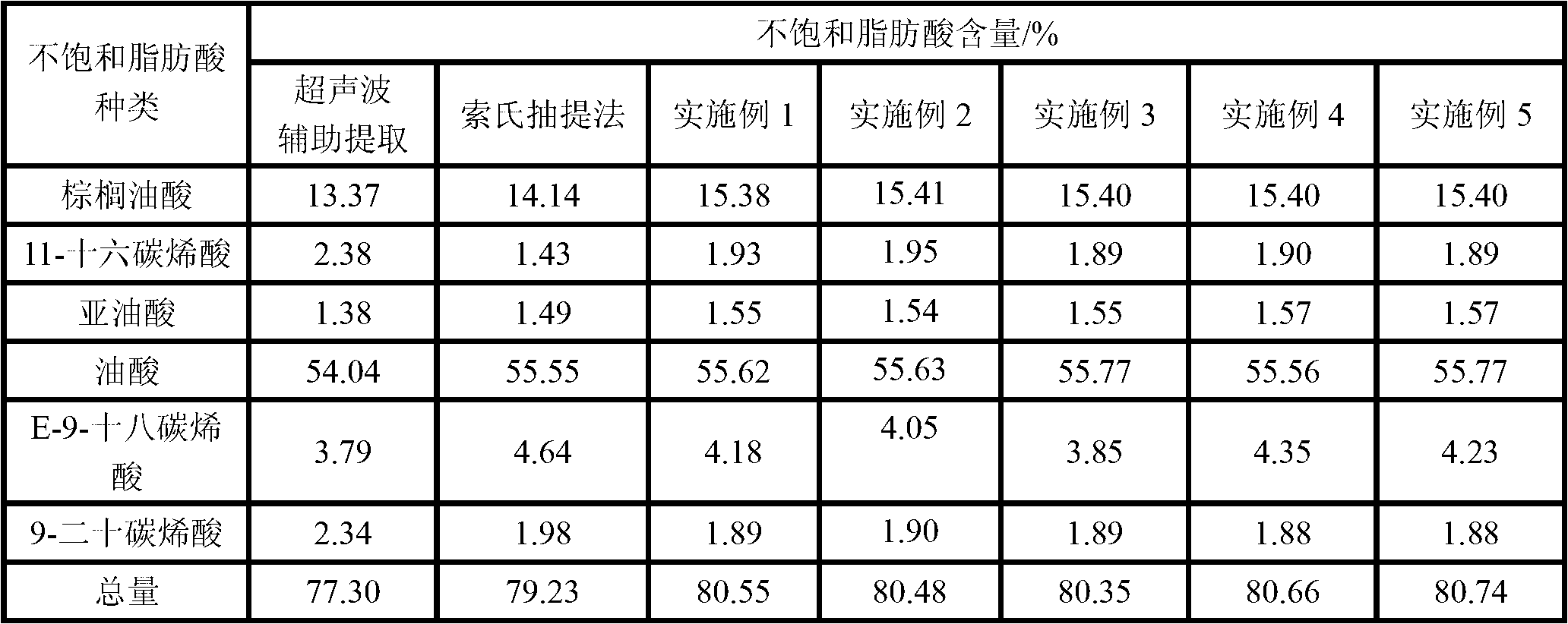

Examples

Embodiment 1

[0024] Follow the steps below to extract macadamia nut oil:

[0025] 1. Shell fresh macadamia nuts, crush the nuts to 20 meshes, dry them in an oven at 60°C to constant weight, weigh 1kg and place them in the barrel of a 2L extraction kettle;

[0026] 2. Turn on the refrigeration and cold cycle, and set the temperature of the water tank to 2°C;

[0027] 3. Turn on the heating power, set the extraction temperature to 45°C, the temperature of the separation kettle Ⅰ to 50°C, and the temperature of the separation kettle Ⅱ to 35°C;

[0028] 4. Fully open the cylinder valve, CO 2 Intake valve, CO 2 After the gas passes through the purifier, it enters the cold box for liquefaction. After the temperature reaches the set value, the CO is turned on. 2 pump, CO 2 The gas is pumped into the extraction kettle after passing through the purifier and heater, and the pressure is adjusted to 35MPa to make it into supercritical carbon dioxide. In the extraction kettle, it is fully contacted...

Embodiment 2

[0031] Follow the steps below to extract macadamia nut oil:

[0032] 1. Shell the fresh macadamia nuts, crush the kernels to 40 meshes, dry them in an oven at 60°C to constant weight, weigh 1.5kg and place them in the barrel of a 2L extraction kettle;

[0033] 2. Turn on the refrigeration and cold cycle, and set the temperature of the water tank to 2°C;

[0034] 3. Turn on the heating power, set the extraction temperature to 50°C, the temperature of the separation tank I to 55°C, and the temperature of the separation tank II to 32°C;

[0035] 4. Fully open the cylinder valve, CO 2 Intake valve, CO 2 After the gas passes through the purifier, it enters the cold box for liquefaction. After the temperature reaches the set value, the CO is turned on. 2 pump, CO 2 The gas is pumped into the extraction kettle after passing through the purifier and heater, and the pressure is adjusted to 20MPa to make it into supercritical carbon dioxide. In the extraction kettle, it is fully conta...

Embodiment 3

[0038] Follow the steps below to extract macadamia nut oil:

[0039] 1. Shell the fresh macadamia nuts, crush the kernels to 60 meshes, dry them in an oven at 60°C to constant weight, weigh 2kg and place them in the barrel of a 2L extraction kettle;

[0040] 2. Turn on the refrigeration and cold cycle, and set the temperature of the water tank to 3°C;

[0041] 3. Turn on the heating power, set the extraction temperature to 32°C, the temperature of the separation kettle Ⅰ to 60°C, and the temperature of the separation kettle Ⅱ to 35°C;

[0042] 4. Fully open the cylinder valve, CO 2 Intake valve, CO 2 After the gas passes through the purifier, it enters the cold box for liquefaction. After the temperature reaches the set value, the CO is turned on. 2 pump, CO 2 The gas is pumped into the extraction kettle after passing through the purifier and heater, and the pressure is adjusted to 35MPa to make it into supercritical carbon dioxide. In the extraction kettle, it is fully co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com