Novel heat-conducting conductive elastomer material and preparation method thereof

An elastomer material and elastomer technology, which is applied in the field of new thermally and electrically conductive elastomer materials and its preparation, can solve the problems that electromagnetic shielding cannot achieve better results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

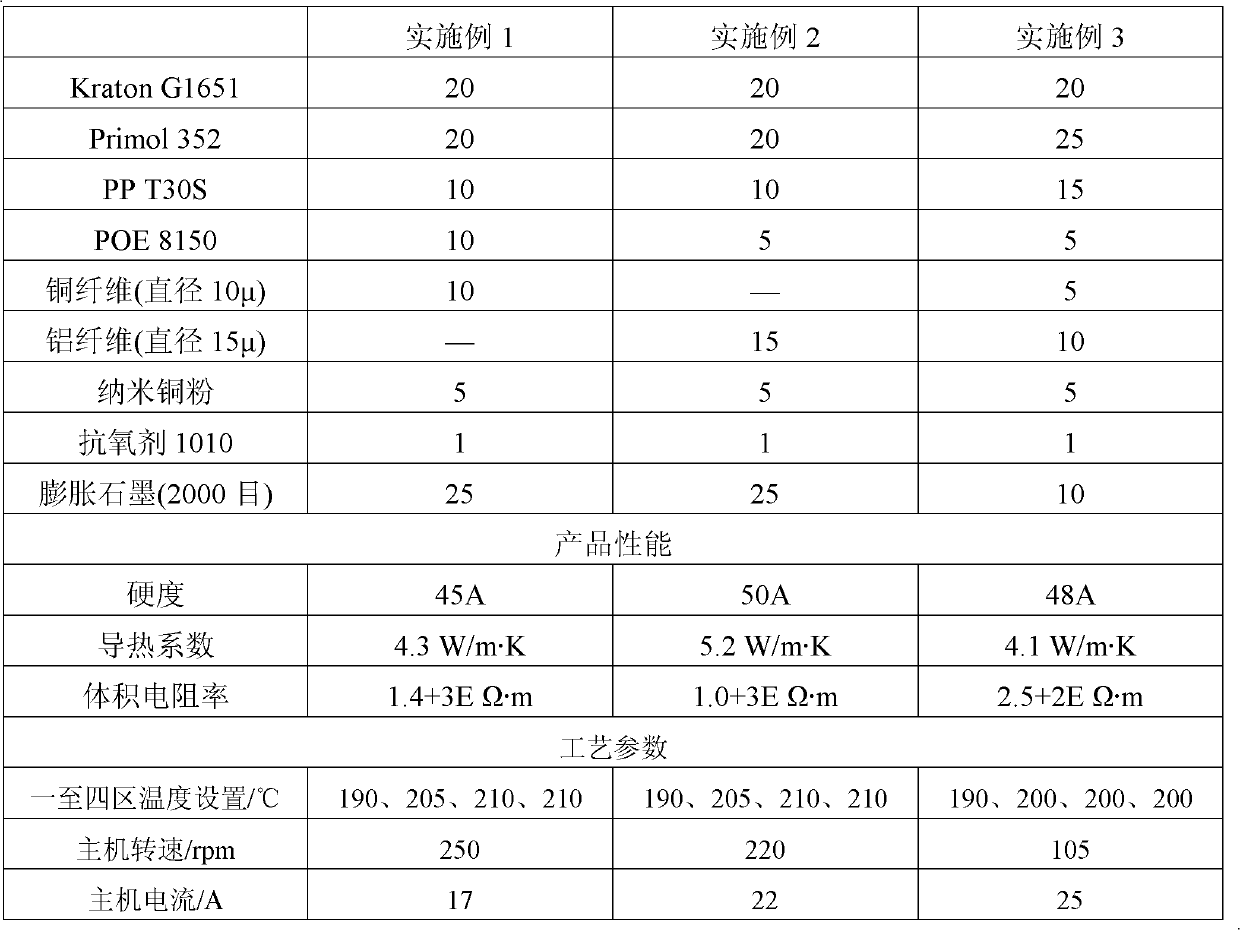

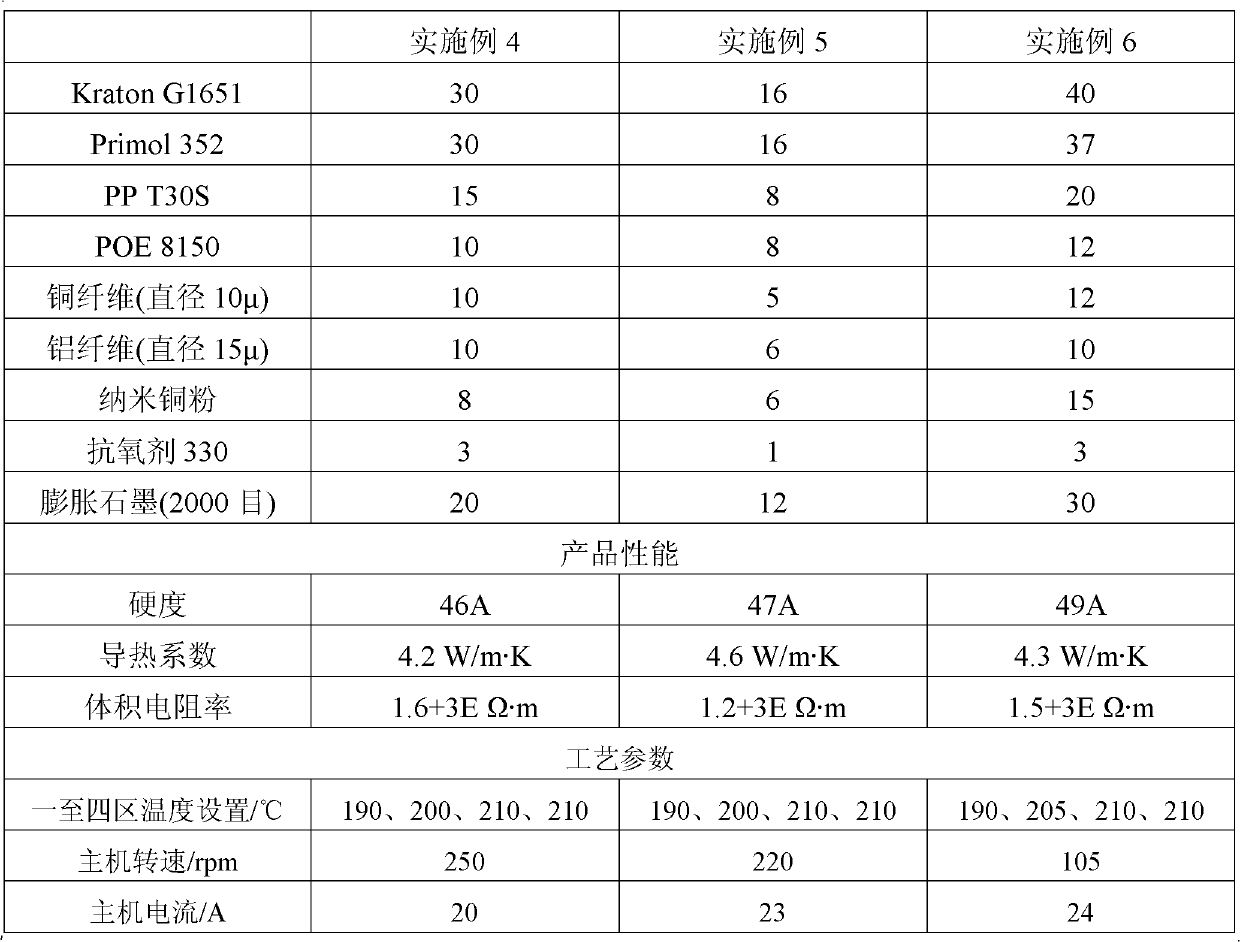

[0023] According to the amount of each component in Table 1 and Table 2, add the raw material styrene elastomer, mineral oil, polyolefin, nano-copper powder, antioxidant and expanded graphite into the high mixer, and mix at a low speed for 8 minutes; mix the raw materials Add it into the feeding hopper of the twin-screw extruder of the equipment; add the metal fiber into the side feeding hopper of the twin-screw extruder; start the twin-screw extruder to extrude and granulate to obtain the product. The process parameters of each embodiment are shown in Table 1 and Table 2, the product performance test results obtained in Examples 1-3 are shown in Table 1, and the product performance test results obtained in Examples 4-6 are shown in Table 2.

[0024] The consumption of each component in the embodiment 1~3 of table 1, product performance testing result and process parameter

[0025]

[0026] The consumption of each component in table 2 embodiment 4~6, product performance tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com