Preparation method of energy-saving heat mirror film insulating glass

A technology of hot mirror and glass, which is applied in the field of preparation of energy-saving hot mirror film insulating glass, which can solve the problems of film laying failure, door and window profiles, increased pressure on hardware, edge folds of hot mirror film, etc., and achieve simple process operation Ease of operation, good appearance and performance, and easy control of process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

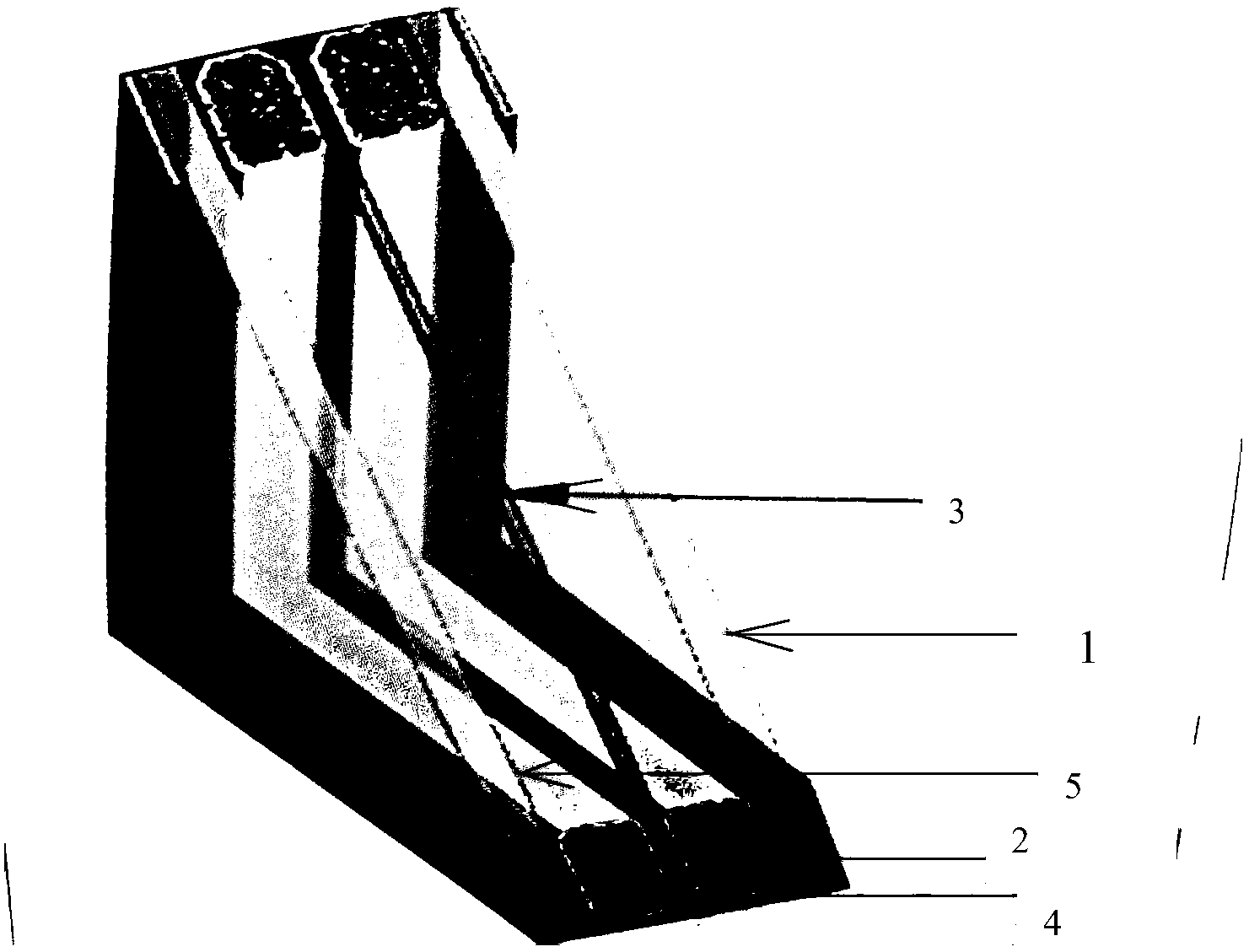

[0036] like figure 1 The configuration of the shown energy-saving heat mirror film insulating glass:

[0037] 15 white steel homogeneous (glass) + 12A junction (spacer) + hot mirror film + 12A junction (spacer) + 15 white steel homogeneous (glass)

[0038] 10 white steel+12A junction+hot mirror film+12A junction+8 white steel+1.52PVB+8 white steel

[0039] (2) Specification: 1985*8815

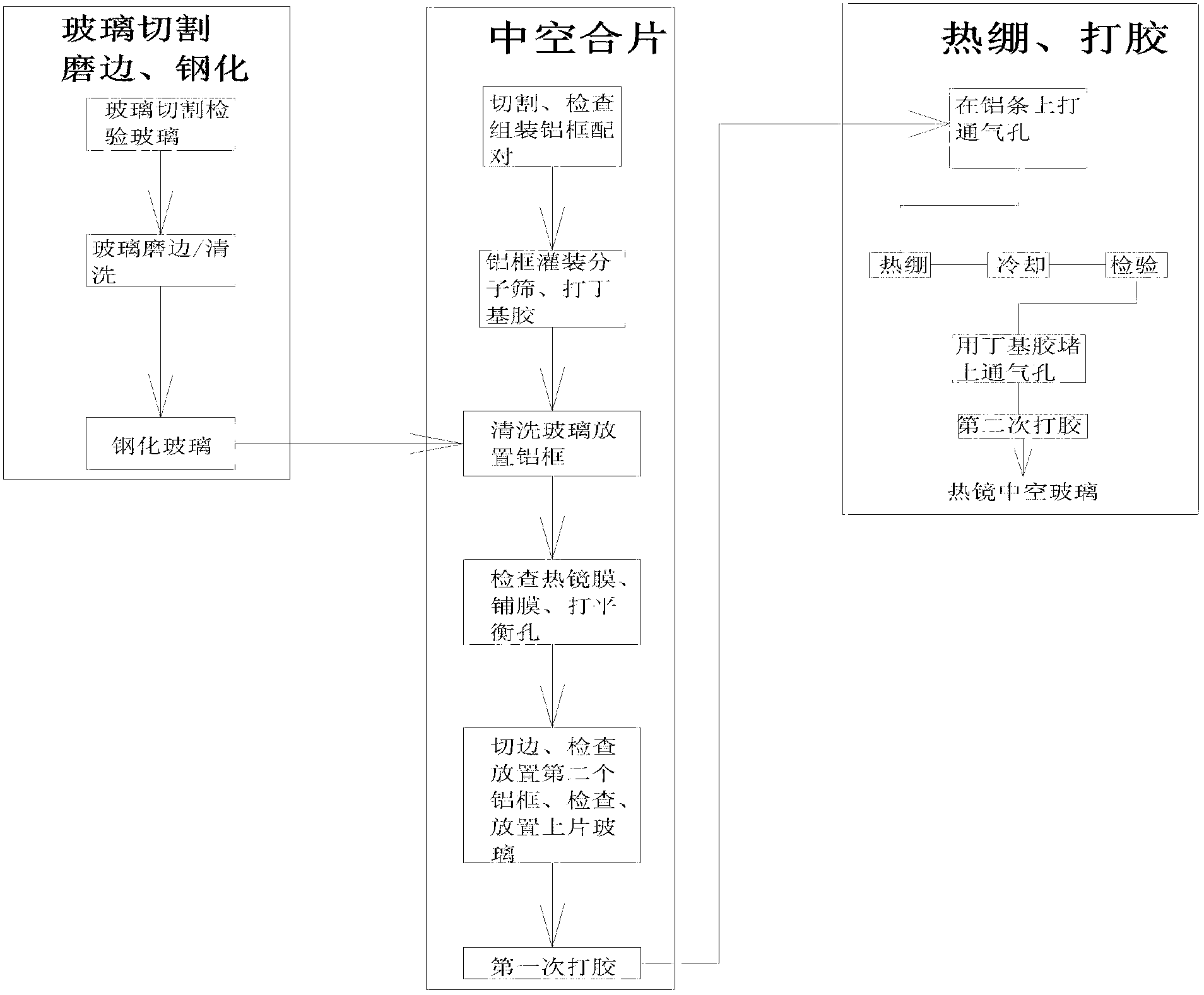

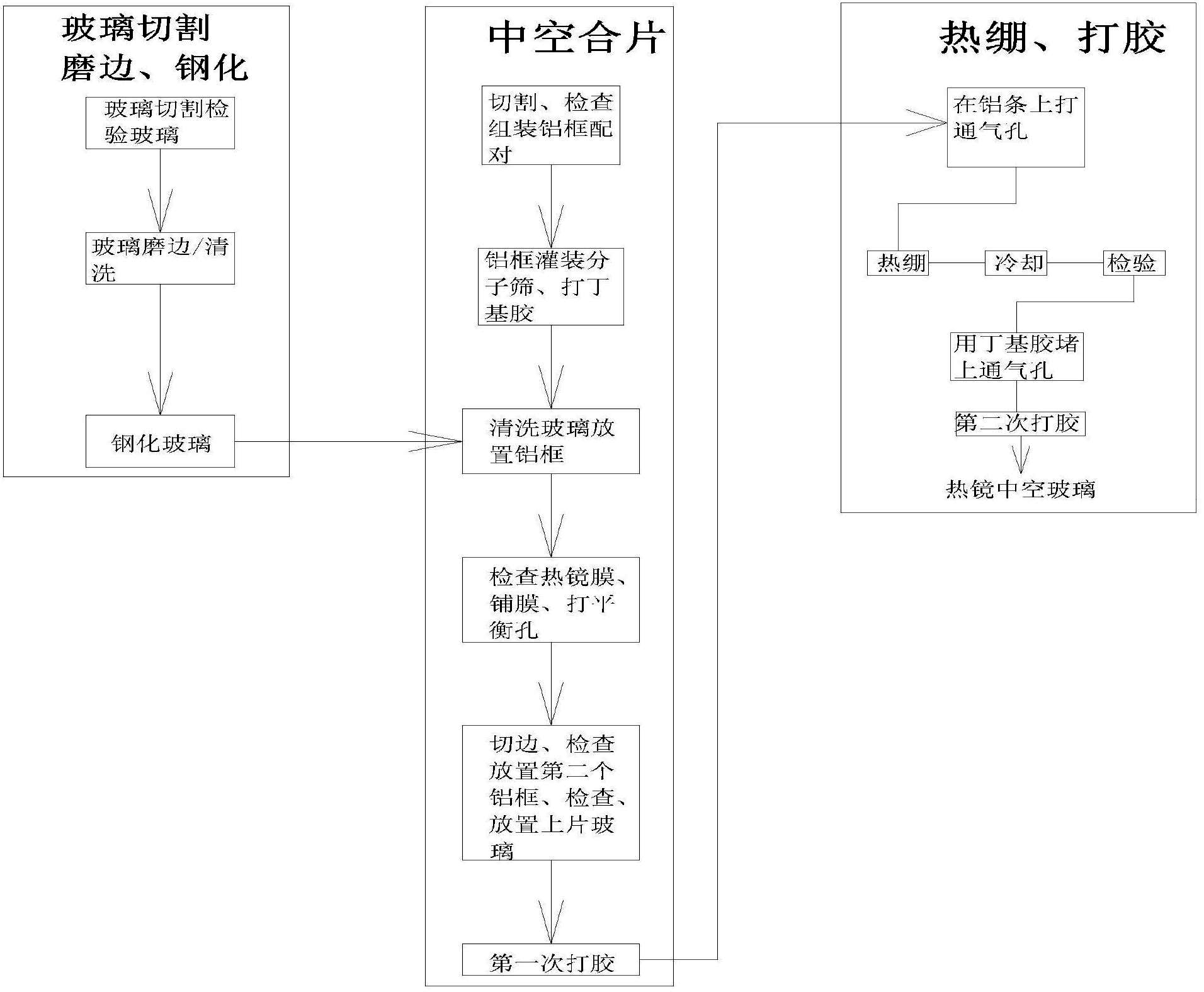

[0040] The preparation process is as follows:

[0041] 1. A 100,000-level purification room is used, and the temperature is required to be controlled at 20±3°C, and the relative humidity is within 25%; to prevent the space environment from polluting the hot mirror film layer; and to facilitate the storage of the hot mirror film.

[0042] 2. Before laying the film, the staff should wear special gloves, masks, and protective clothing; prevent sweat and spit from oxidizing the film layer.

[0043] 3. Clean the surface of the first piece of glass, and fix the aluminum frame. When pulling the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com