Sludge dehumidify and drying machine

A drying machine and sludge technology, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of reducing oxygen content, low energy utilization rate, safety risks, etc., and achieve flexible flow adjustment and spreading effect. Uniform, long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

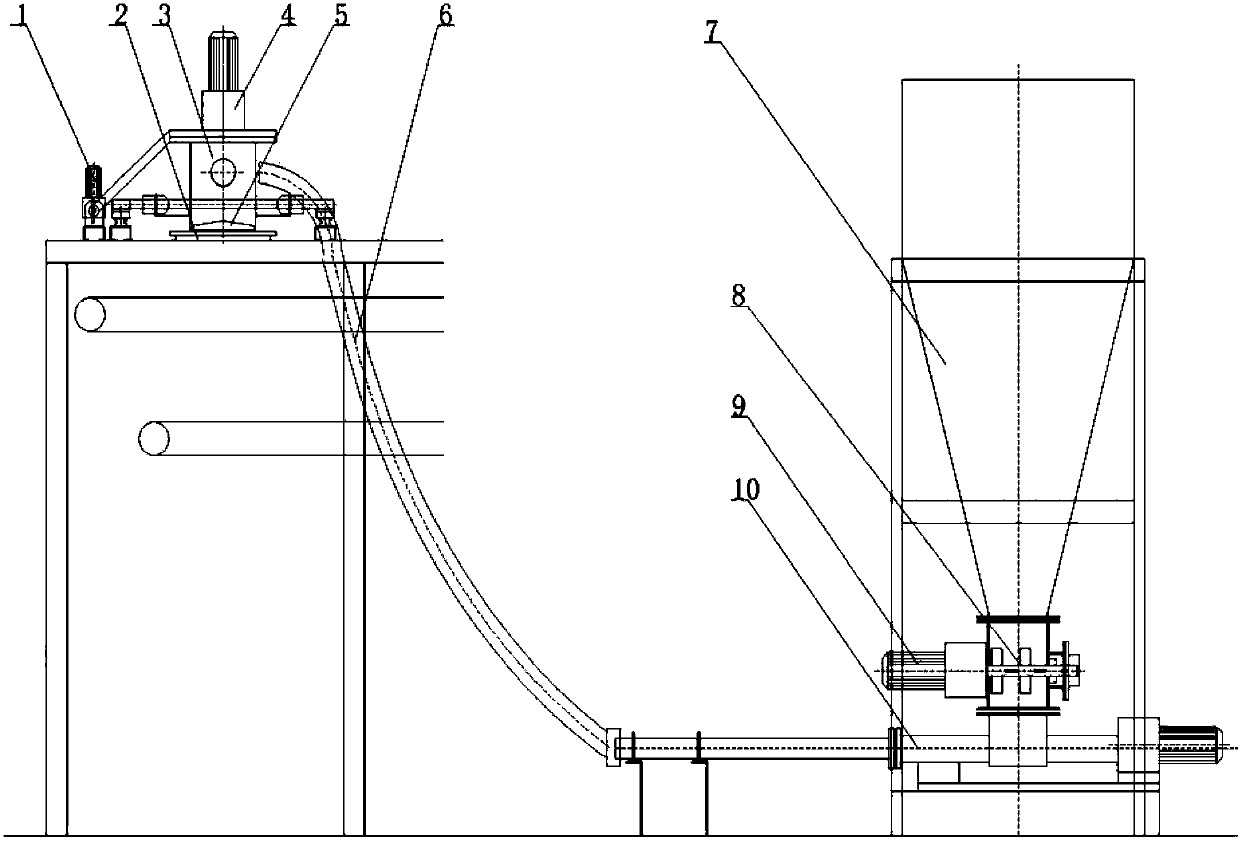

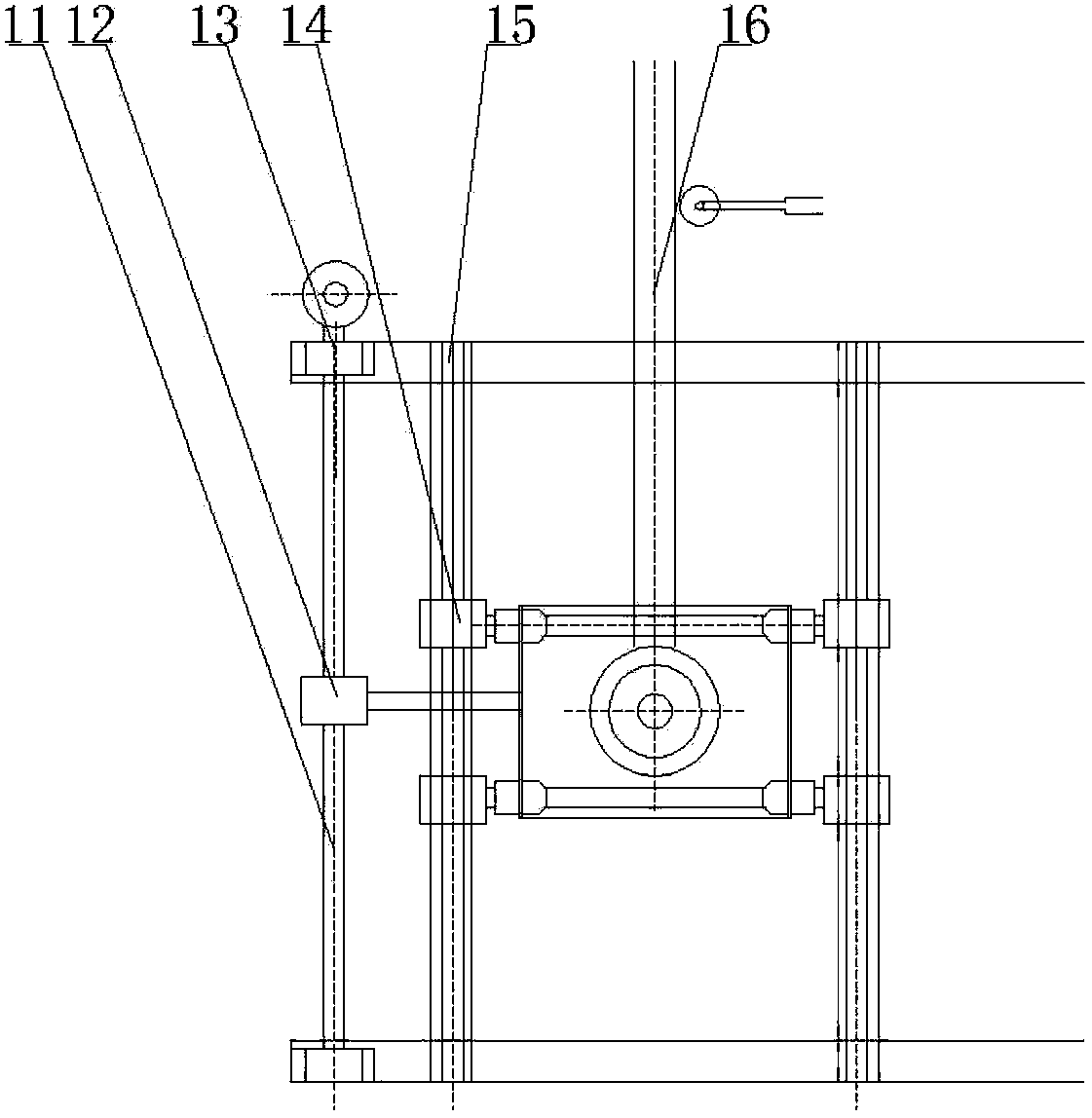

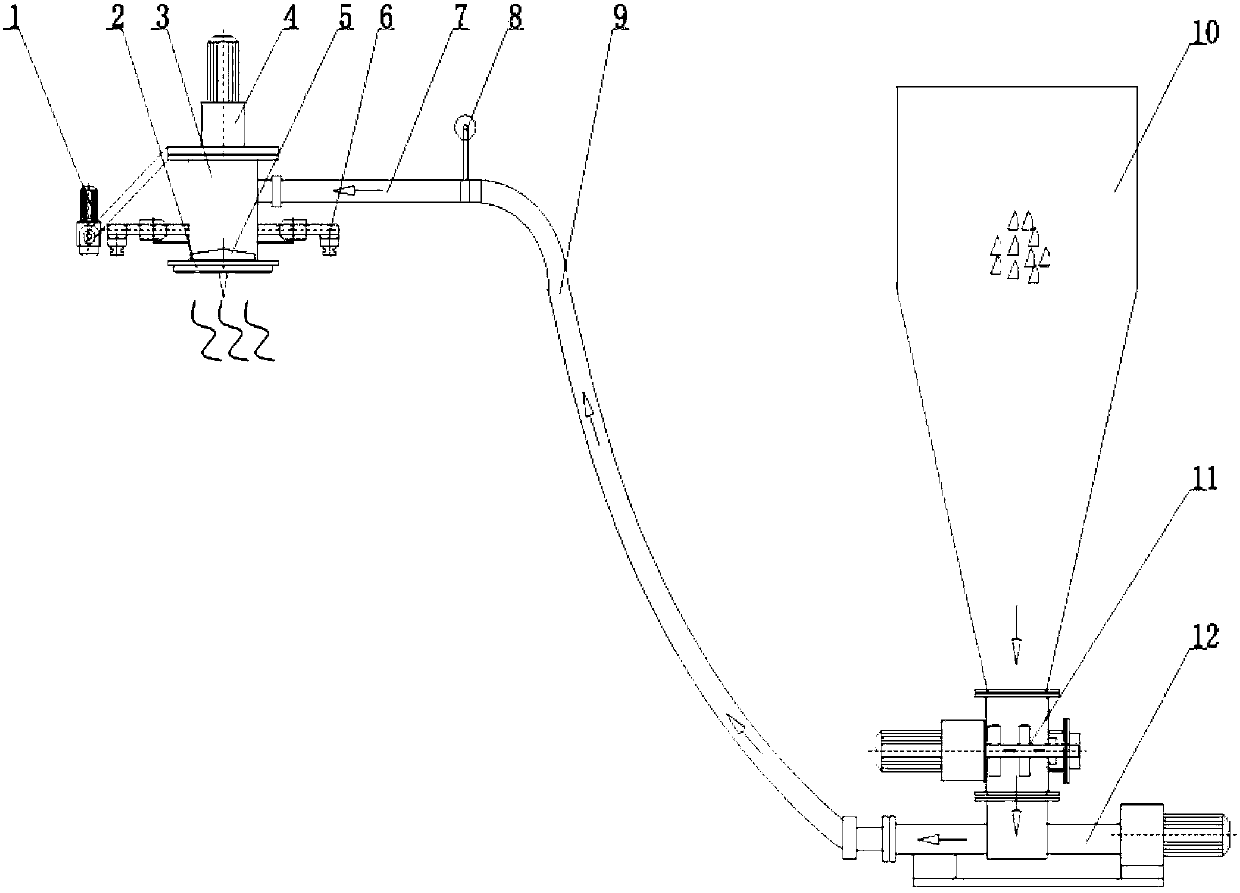

[0044] Sludge dehumidification dryer, such as Figure 5 and Figure 6 As shown, it includes an extruded strip feeding device 21, at least one layer of mesh belt and a heat pump dehumidification drying device 23, the mesh belt is arranged in the drying box 24, and the extruded strip feeding device 21 is arranged on one end of the mesh belt , used to transport the sludge to be dried to the mesh belt. The heat pump dehumidification and drying device 23 is installed in an auxiliary box on the side of the drying body 24 , and the heat pump dehumidification and drying device 23 is connected to the bottom of the drying box through an air supply pipe 33 . Wherein, the mesh belt is arranged in two layers, the first layer of mesh belt 26 and the second layer of mesh belt 27 are layered from top to bottom, and the lower part of the end of the first la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com